Splicing-type solar heating plate

A technology of solar energy and heating plate, applied in the direction of solar thermal energy, solar collector, solar heating system, etc., can solve the problems of wasting manpower, inconvenient disassembly, hurting people, etc., to improve the heating effect, easy to remove, easy to replace and maintain Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

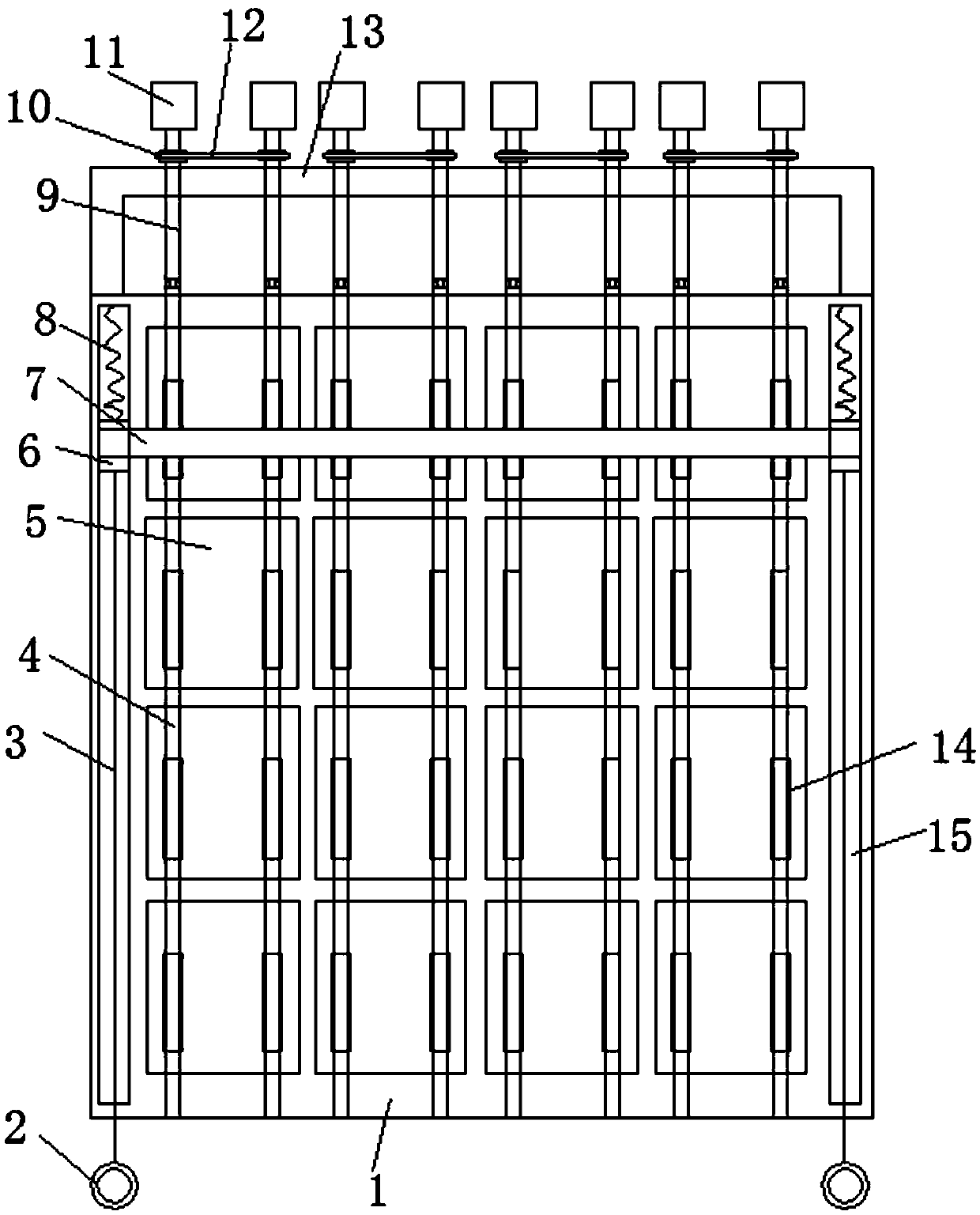

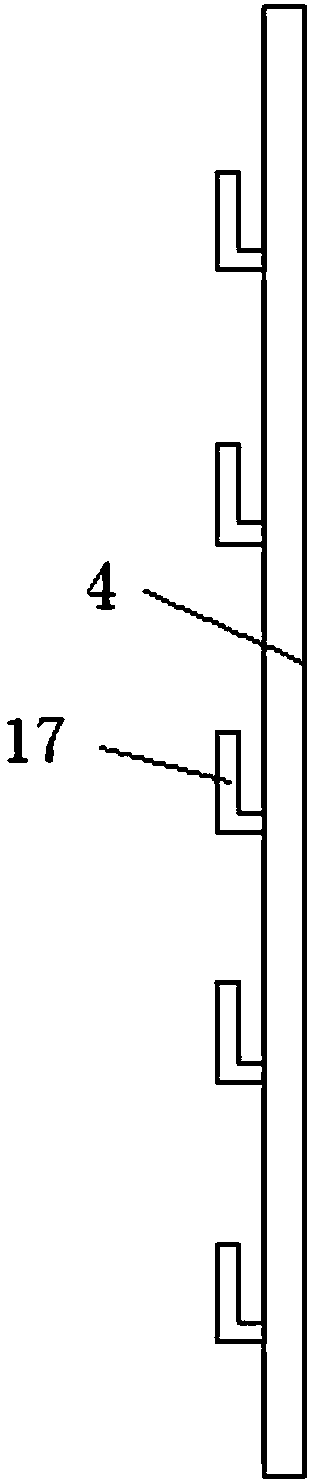

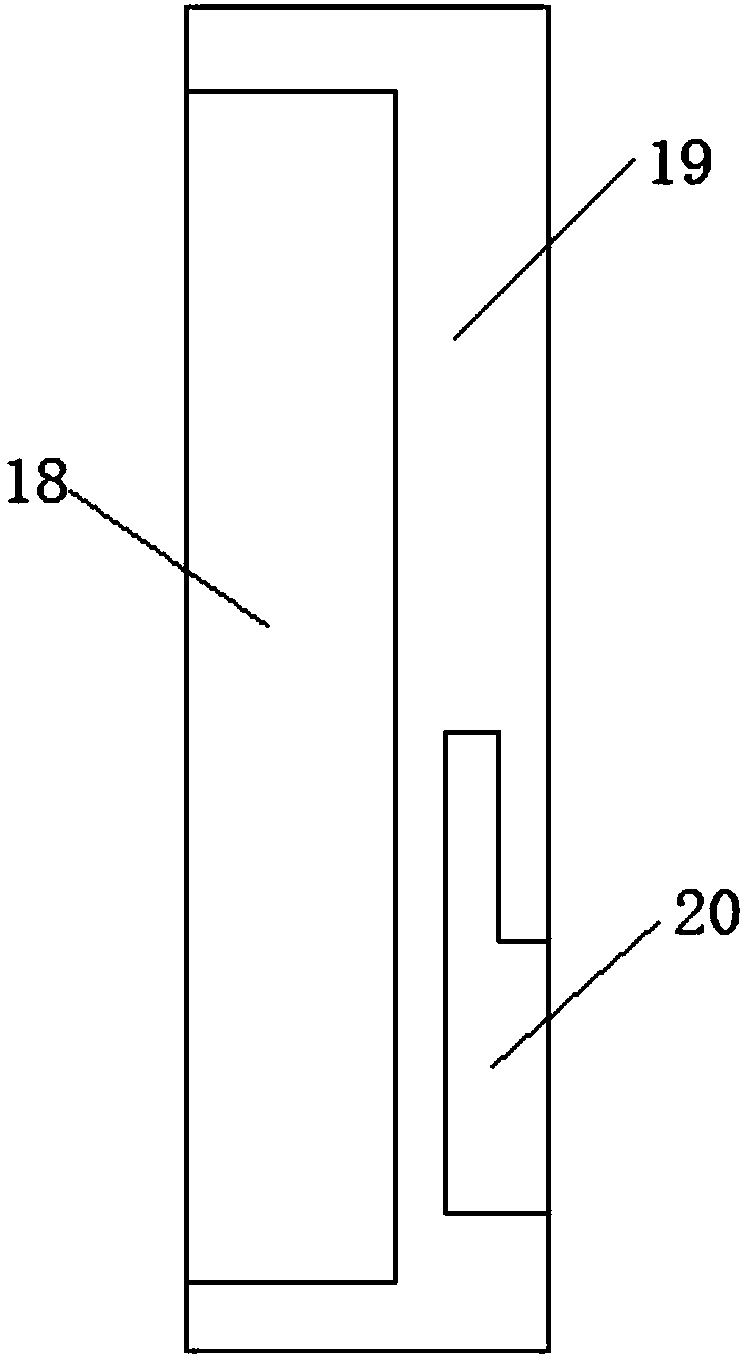

[0018] refer to Figure 1-5 , a spliced solar heating panel, including a fixed plate 1, a plurality of movable holes 21 are opened on the fixed plate 1, and a movable rod 4 is slidably connected to the movable hole 21, and a plurality of array rows are opened on one side wall of the fixed plate 1. The installation groove 5 of cloth, the bottom end of installation groove 5 has two connection holes 14, and the two ends of connection hole 14 communicate with each other with installation groove 5 and movable hole 21 respectively, are provided with installation frame 19 in the installation groove 5, and installation frame 19 is embedded with a solar heating plate 18 on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com