Changeable curved-surface stage

A stage and curved surface technology, applied in the field of multi-variable curved surface stage, can solve the problems of inability to adapt to the diversified needs of the performing arts market and the inability to change the plane structure, and achieve the effects of precise movements, good manufacturing process, and easy control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

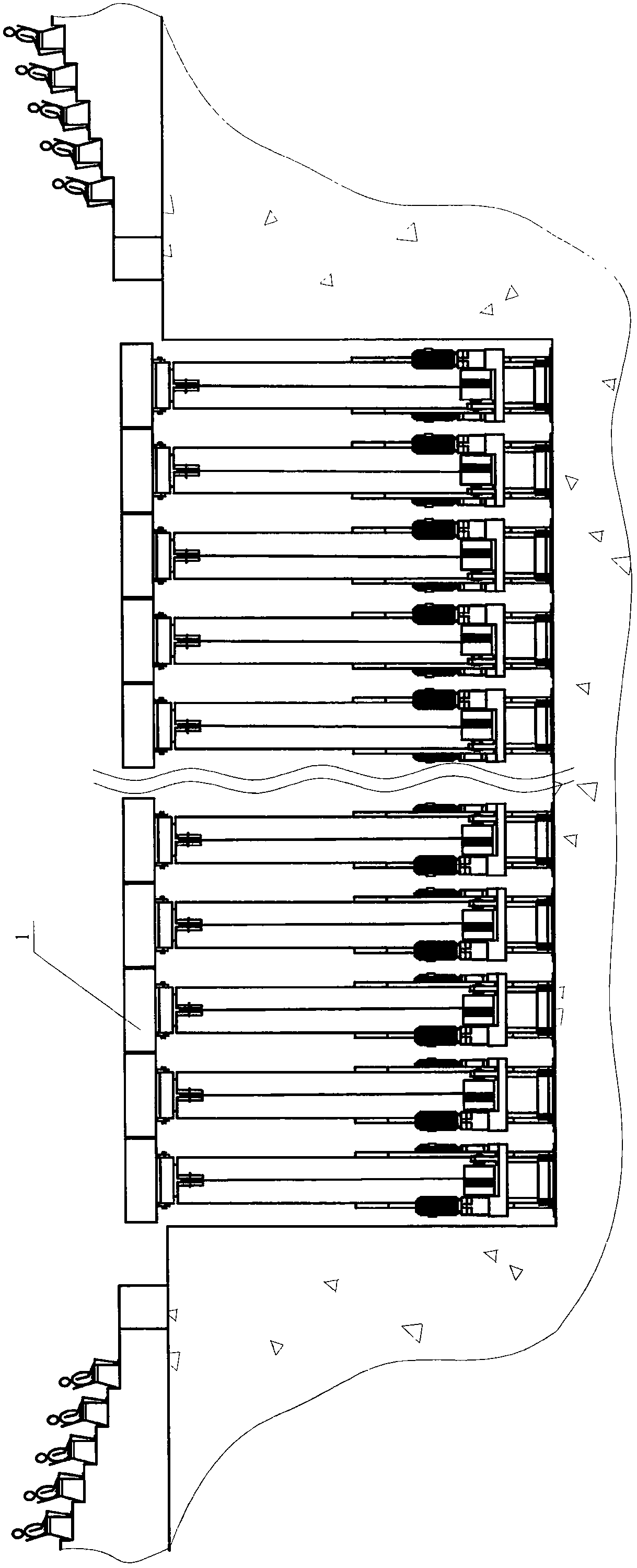

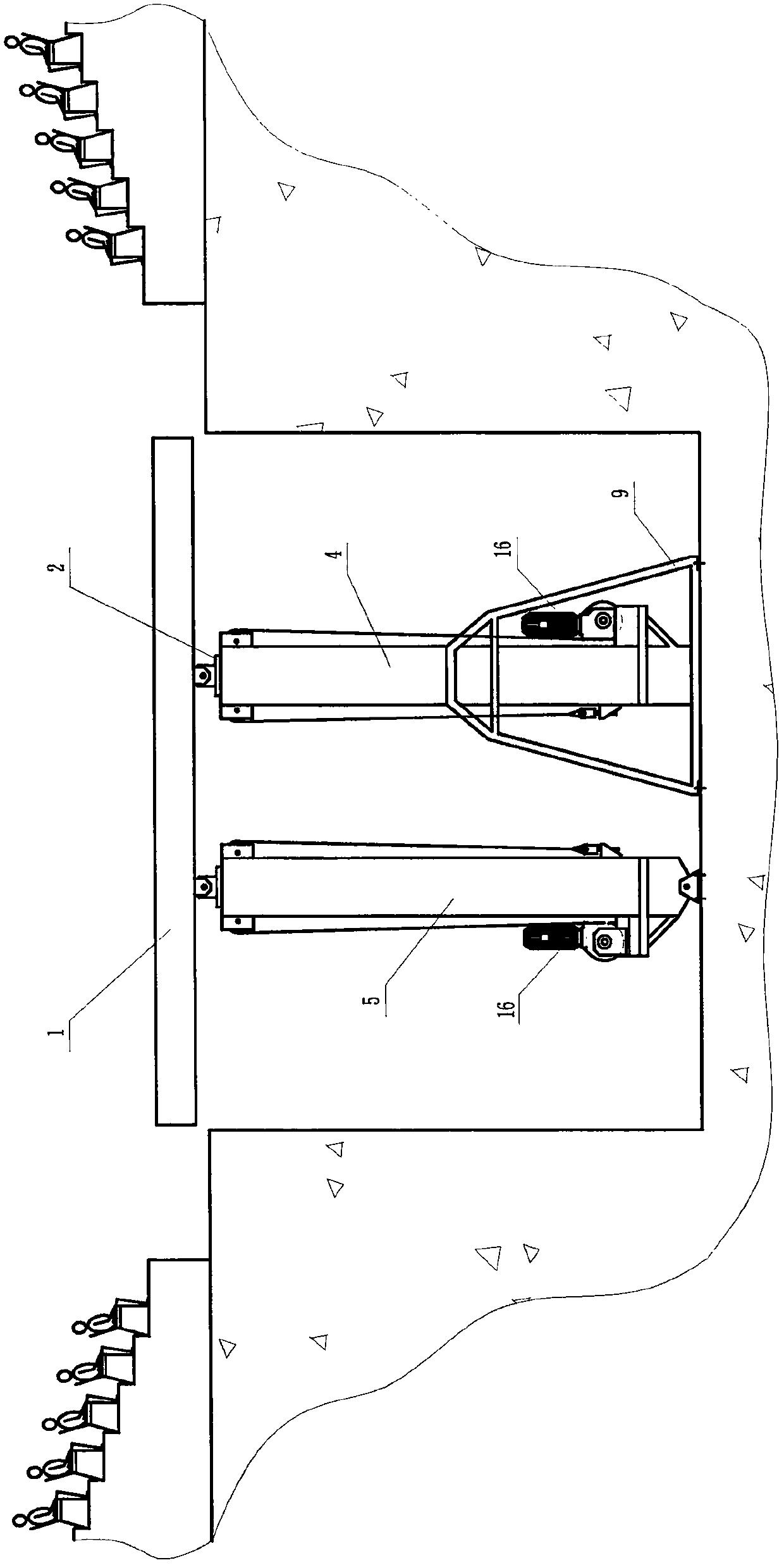

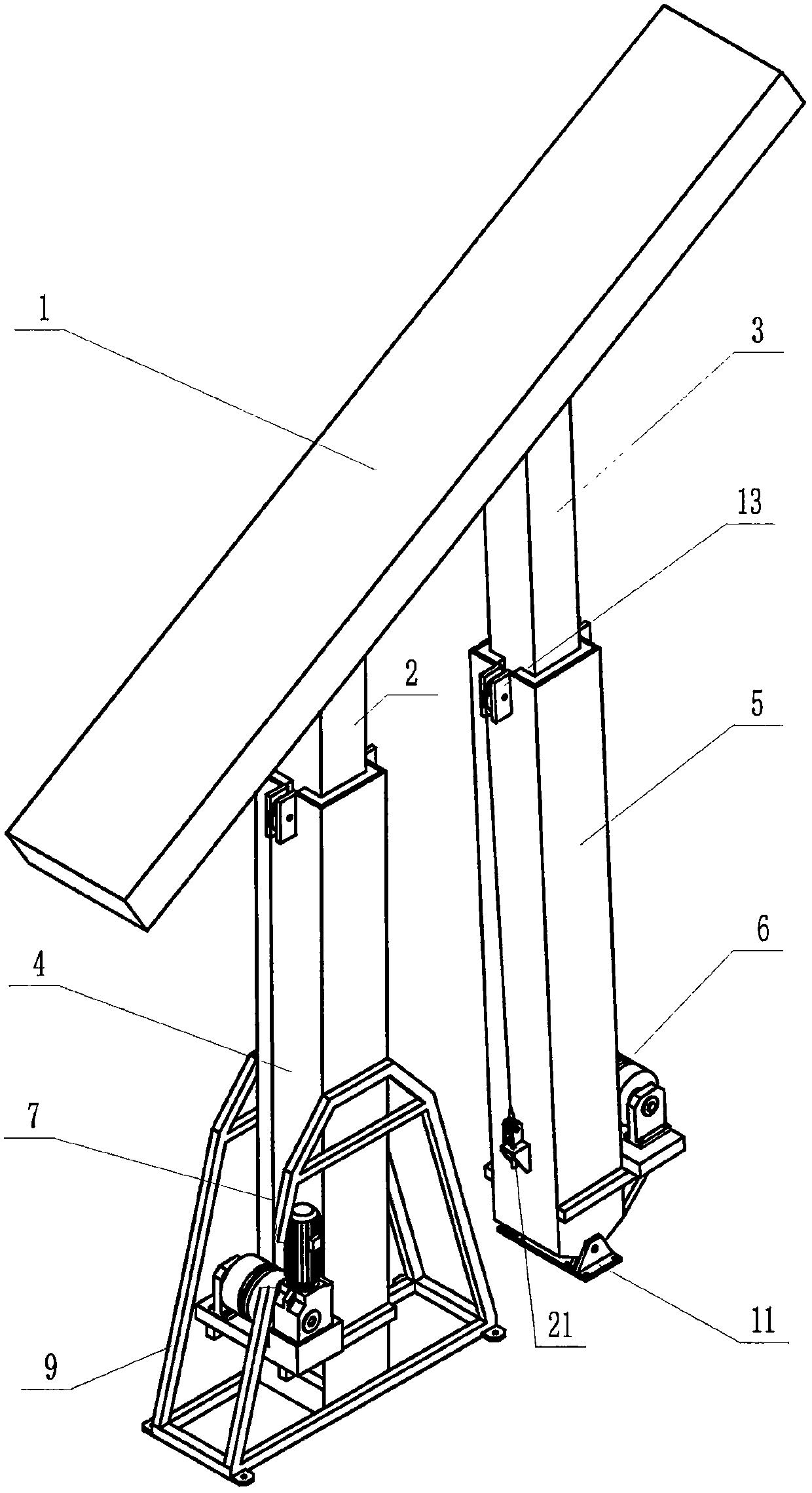

[0022] refer to Figure 1-10 , a stage with variable curved surface, which is composed of a plurality of mutually independent table top units, and the table top unit includes a table top 1 and an independent lifting adjustment device installed under the table top, and all the table tops in the initial state have gaps along the width arranged side by side;

[0023] The lifting adjustment device includes a longitudinally arranged first sliding column 2, a longitudinally arranged second sliding column 3, a fixed sliding sleeve 4, a swinging sliding sleeve 5, a winch 6 and a traction rope 7. The first sliding column and the second sliding sleeve The tops of the two sliding columns are respectively hinged with the lugs 8 at the two ends of the table panel, and the lower section of the first sliding column is built in the fixed sliding sleeve, and the first sliding column can slide up and down relative to the fixed sliding sleeve; the fixed sliding sleeve The sleeve is fixedly conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com