An integrated pipe string for well cementing and sand control and its application method

A pipe string and well cementing technology, which is applied in the field of well cementing and sand control in oil development operations, can solve problems such as failure to achieve bumping pressure, and achieve the effects of reducing development costs, shortening the development cycle of a single well, and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

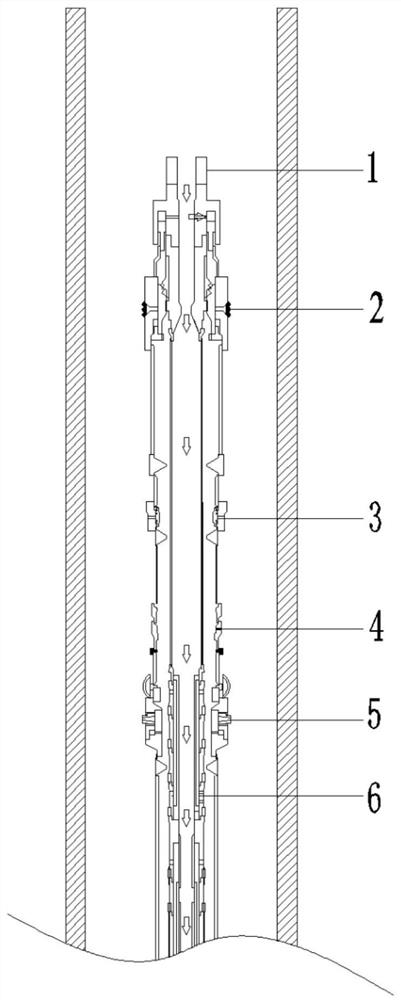

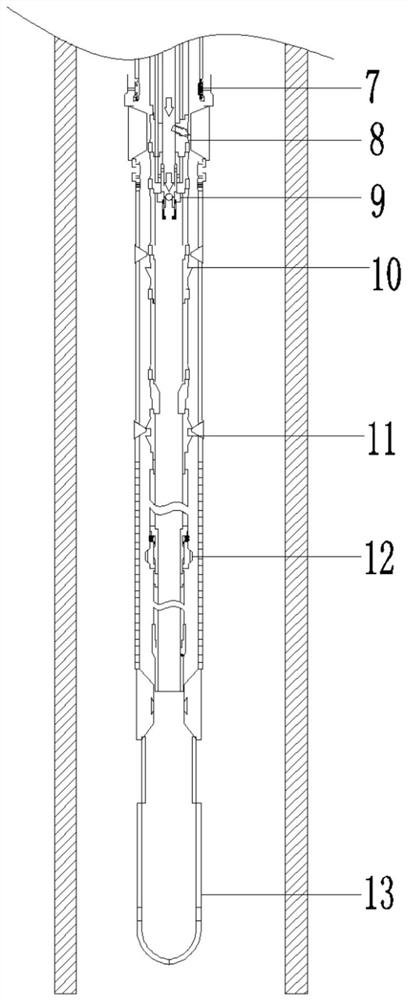

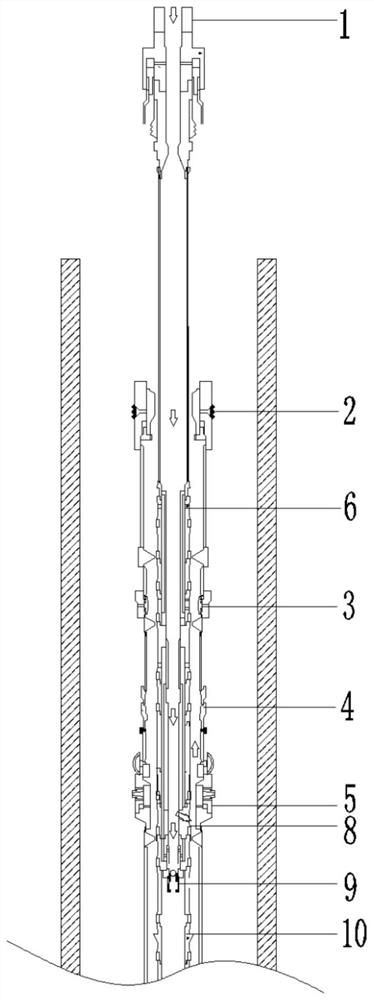

[0033] Below in conjunction with accompanying drawing, the present invention will be further described:

[0034] An integrated pipe string for cementing and sand control, which is composed of an outer pipe string and an inner pipe string. The outer pipe string is sequentially connected with a suspension packer 2, a circulating sliding sleeve 3, and a cementing sliding sleeve from top to bottom. Sleeve 4, outer pipe packer 5, filling sliding sleeve 7 and single-flow valve guide shoe 13, the inner pipe string includes bumper nipple 1, balance mechanism 6, filling mechanism 8, classification Ball seat 9, closing tool 10, switch tool 11, positioner 12. Through this pipe string, the cementing and sand control operation can be completed in one trip of the pipe string in the slim hole, and the effective sealing of the mudstone and water layer in the cementing section can be realized, and the operation requirements of gravel packing in the sand control section can be realized.

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com