A gas supply path and method for ensuring remote control online redundancy of multiple pneumatic valves

A pneumatic valve and air circuit technology, applied in the direction of valve operation/release device, valve details, valve device, etc., to reduce risk and improve reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

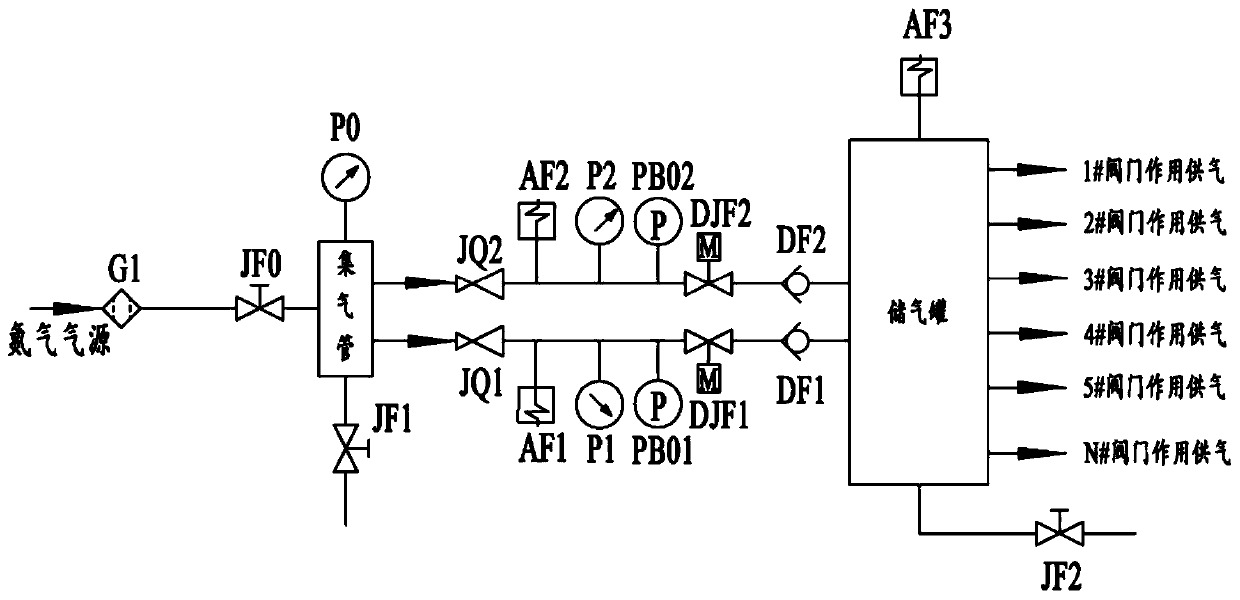

[0033] like figure 1 As shown, the present invention discloses a remote control online redundant air supply circuit that guarantees multiple pneumatic valves. There is an air source cut-off valve JF0 on the pipeline connecting the air inlet end of the air pipe to the air source, and the air supply can be realized by manually opening the air source stop valve JF0, and a filter is installed on the pipeline between the air source and the air source stop valve JF0. G1 is used to filter the excess. In this embodiment, the gas source is nitrogen gas source, and the gas collecting pipe is set in a circular structure as a whole to play a role in stabilizing the pressure. Three pressure gauges P0; the gas collection pipe has a first gas outlet and a second gas outlet, the gas storage tank has a first gas inlet and a second gas inlet, and the first gas outlet passes through the first gas inlet and the first gas inlet. The second gas outlet is connected to the second air inlet through t...

Embodiment 2

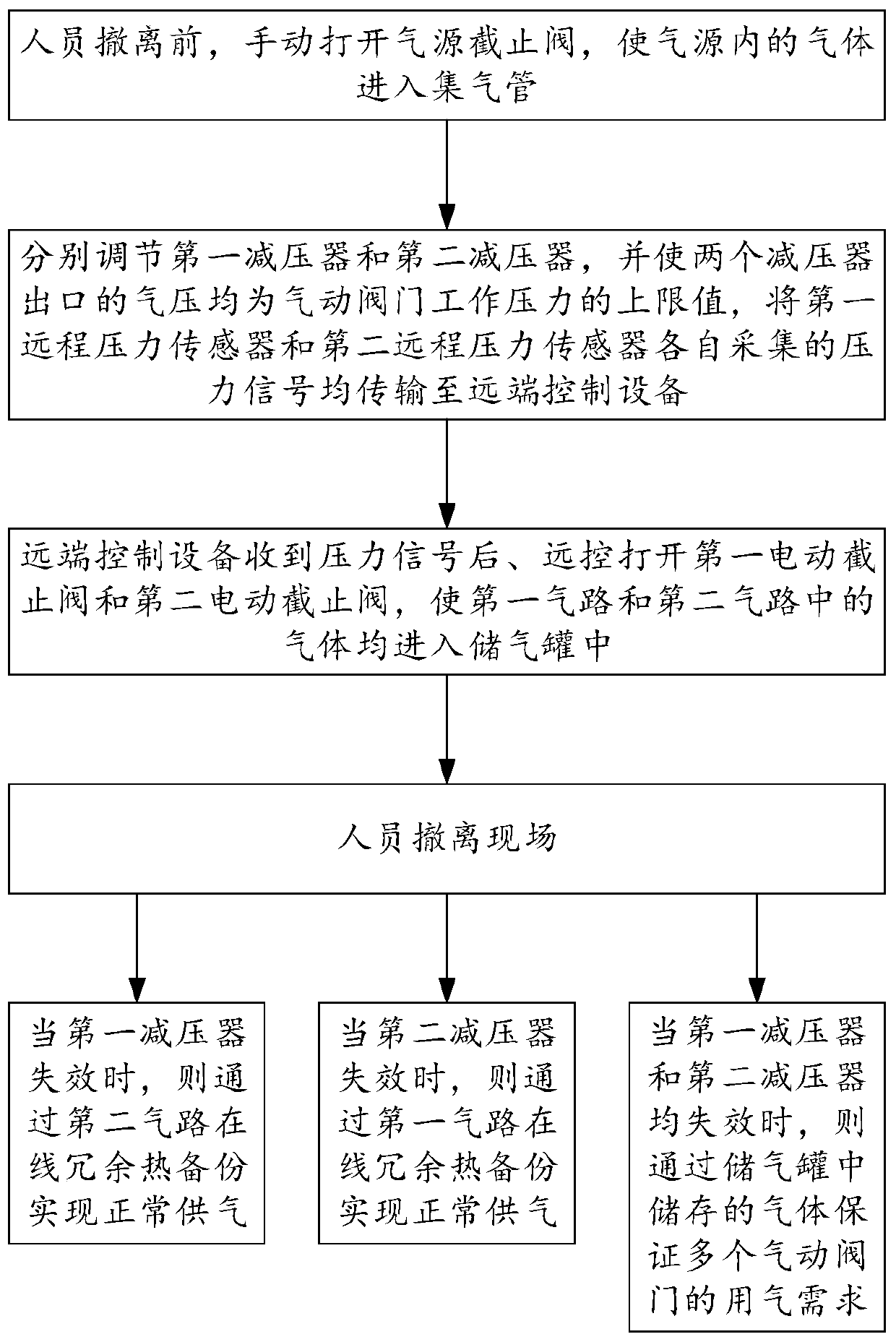

[0038] like figure 1 , 2 As shown, based on the same inventive concept as Embodiment 1, this embodiment discloses a gas supply method that uses the above-mentioned gas supply circuit to ensure remote control of multiple pneumatic valves and online redundancy. In the launch process, the supply The gas method includes the following steps:

[0039] Step 1. Before personnel evacuate, manually open the gas source cut-off valve JF0, then high-pressure nitrogen passes through the filter G1 to achieve the purpose of allowing the gas in the gas source to enter the gas collection pipe. The gas source pressure displayed on the third pressure gauge P0 is p0 .

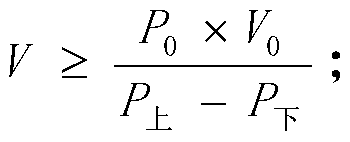

[0040] Step 2, adjust the first pressure reducer JQ1 and the second pressure reducer JQ2 respectively, and make the air pressure at the outlet of the two pressure reducers equal to the upper limit value P of the working pressure of the pneumatic valve 上 , then the air pressure displayed on the first pressure gauge P1 is p1, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com