Biomass marsh gas preprocessing system

A pretreatment and biomass technology, applied in the pipeline system, gas/liquid distribution and storage, fire rescue, etc., can solve the problem of low utilization rate of biogas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

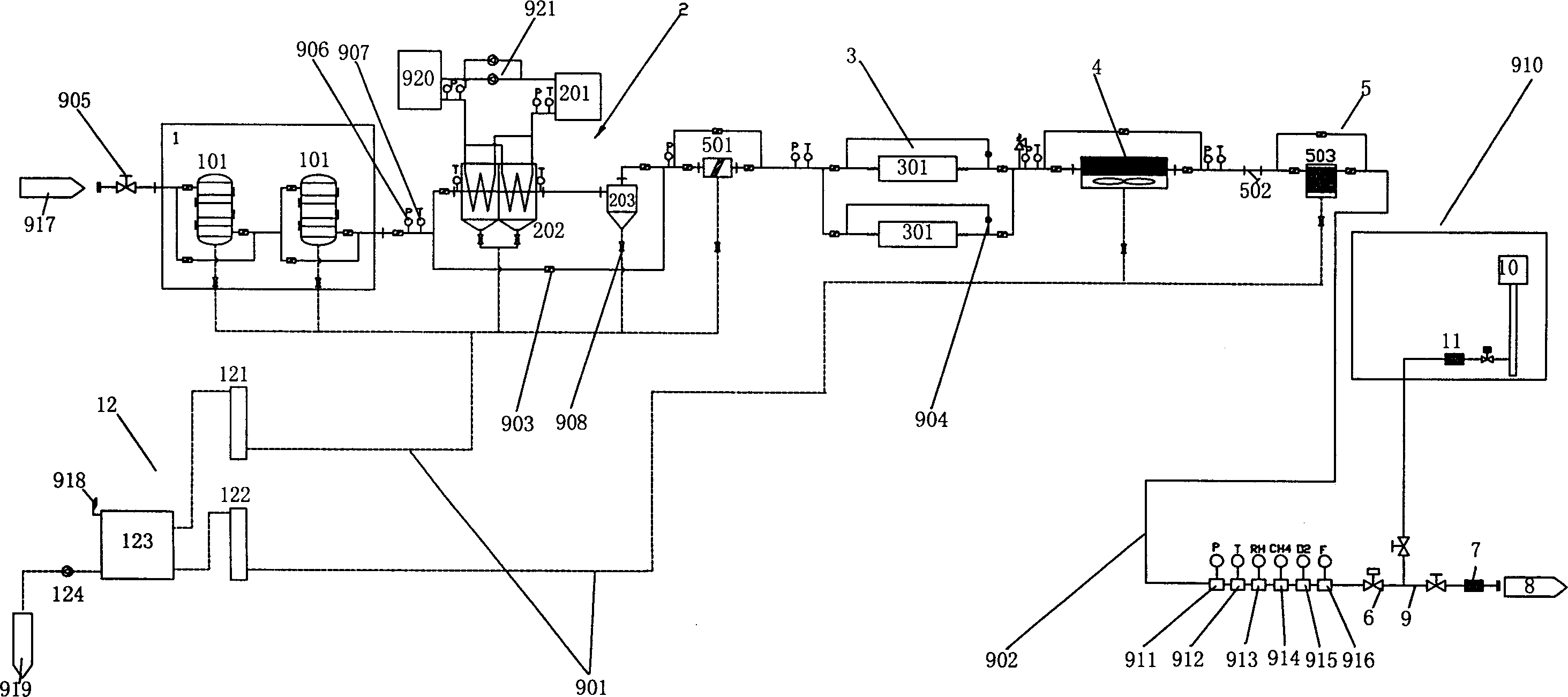

[0020] As shown in Figure 1.

[0021] A biomass biogas pretreatment system, which mainly consists of a desulfurization device 1 composed of two desulfurization tanks 101 connected in series, a water cooler 201, a two-stage shell-and-tube heat exchanger 202, and a cyclone dehydrator 203 Water-cooled biogas dehydration device 2, a Roots blower device composed of two Roots blowers 301 and two self-operated micro-pressure regulators 302 3, an air-cooled radiator 4, a primary filter 501, and a pipeline aisle filter device 5 composed of device 502 and coalescing filter 503, an electromagnetic cut-off valve 6, and a pipeline flame arrester 7; wherein the input end of desulfurization device 1, that is, the input end of desulfurization tank 101, is connected to the biogas pipeline, and the desulfurization device 1 The output end, that is, the output end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com