Propeller test device

A testing device and technology for propellers, applied in the field of propellers, can solve the problems of safety, economy, limitation of testing accuracy, inability to carry out physical tests, etc., and achieve the effects of facilitating promotion, improving testing efficiency, and low manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

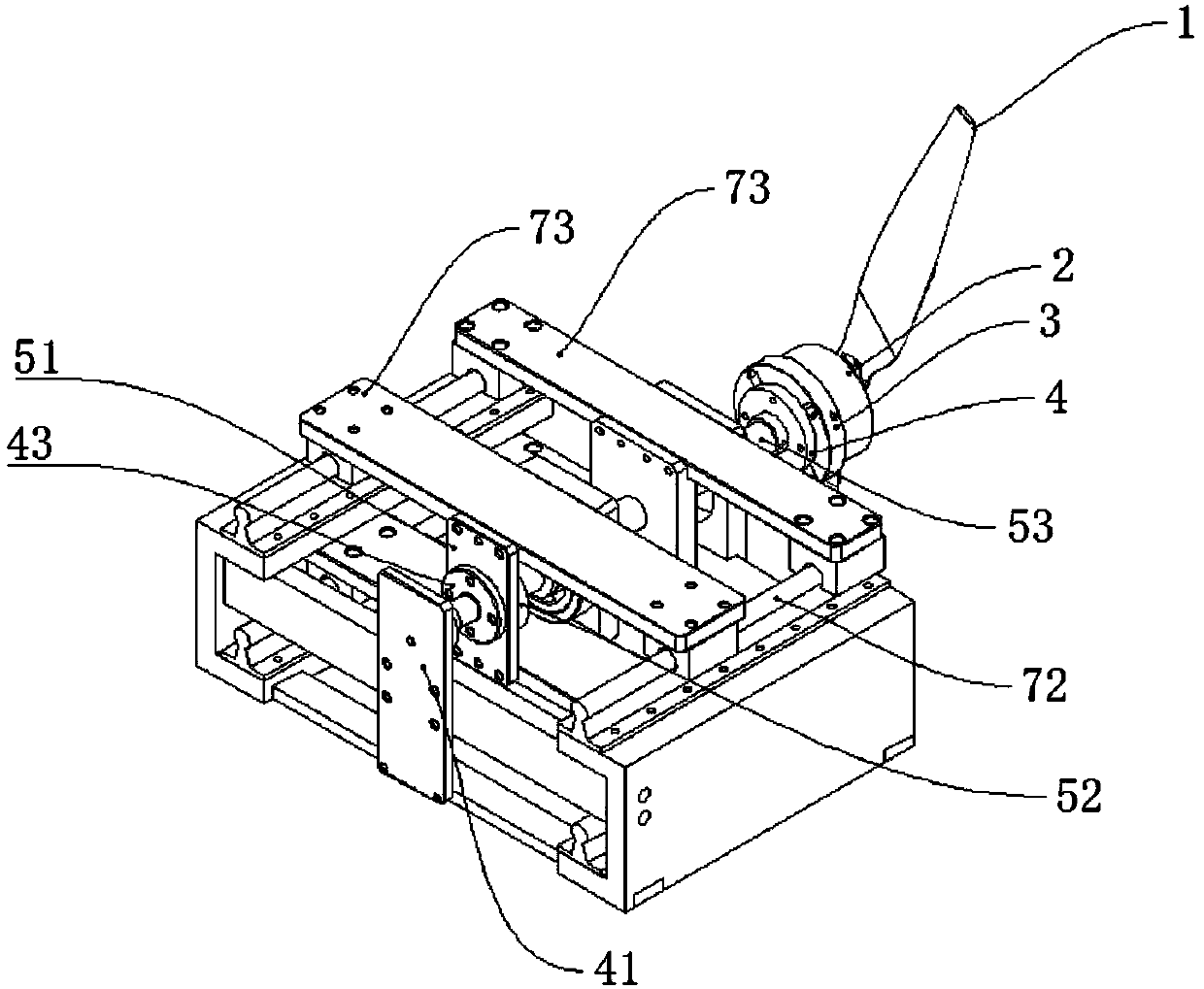

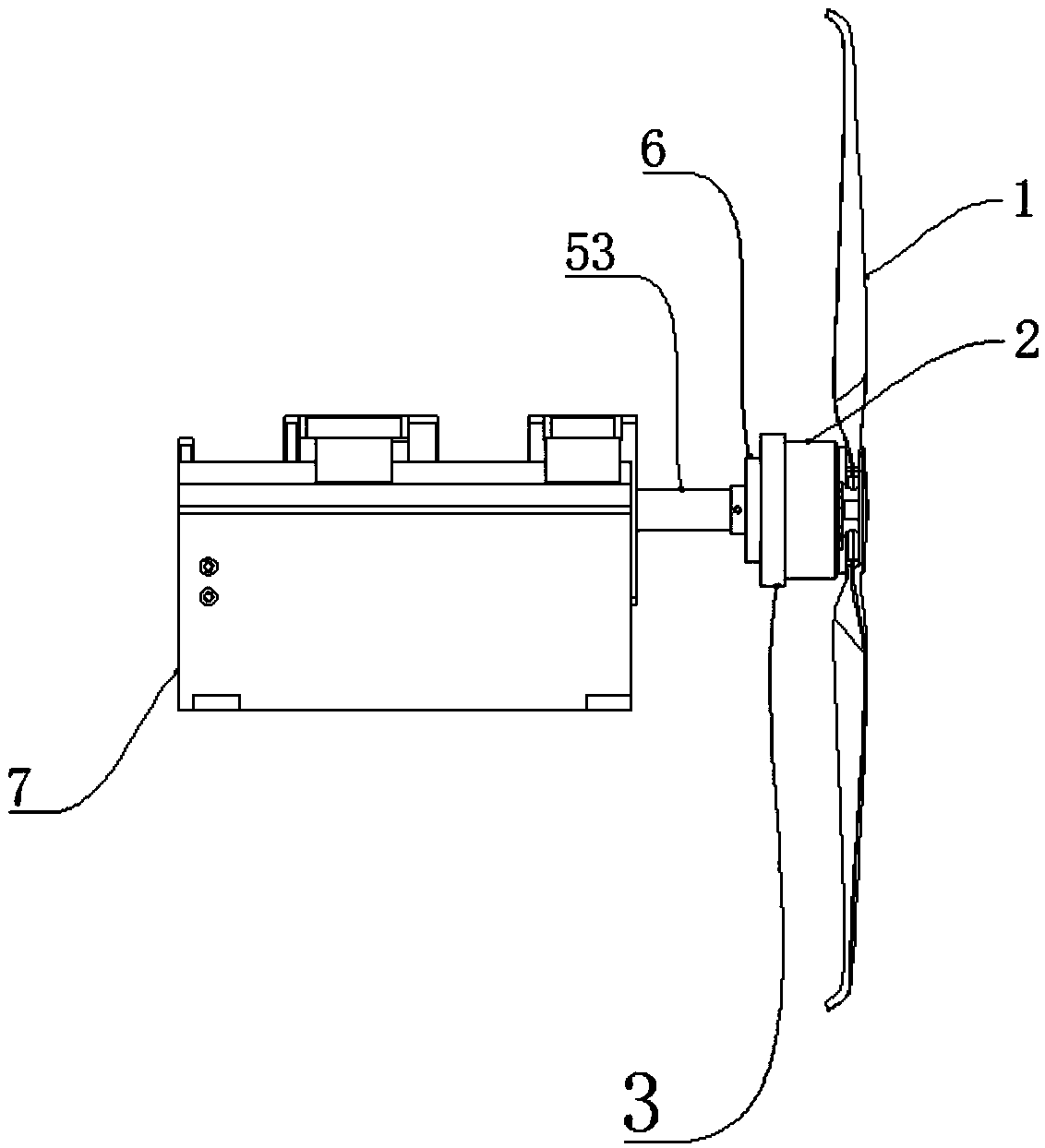

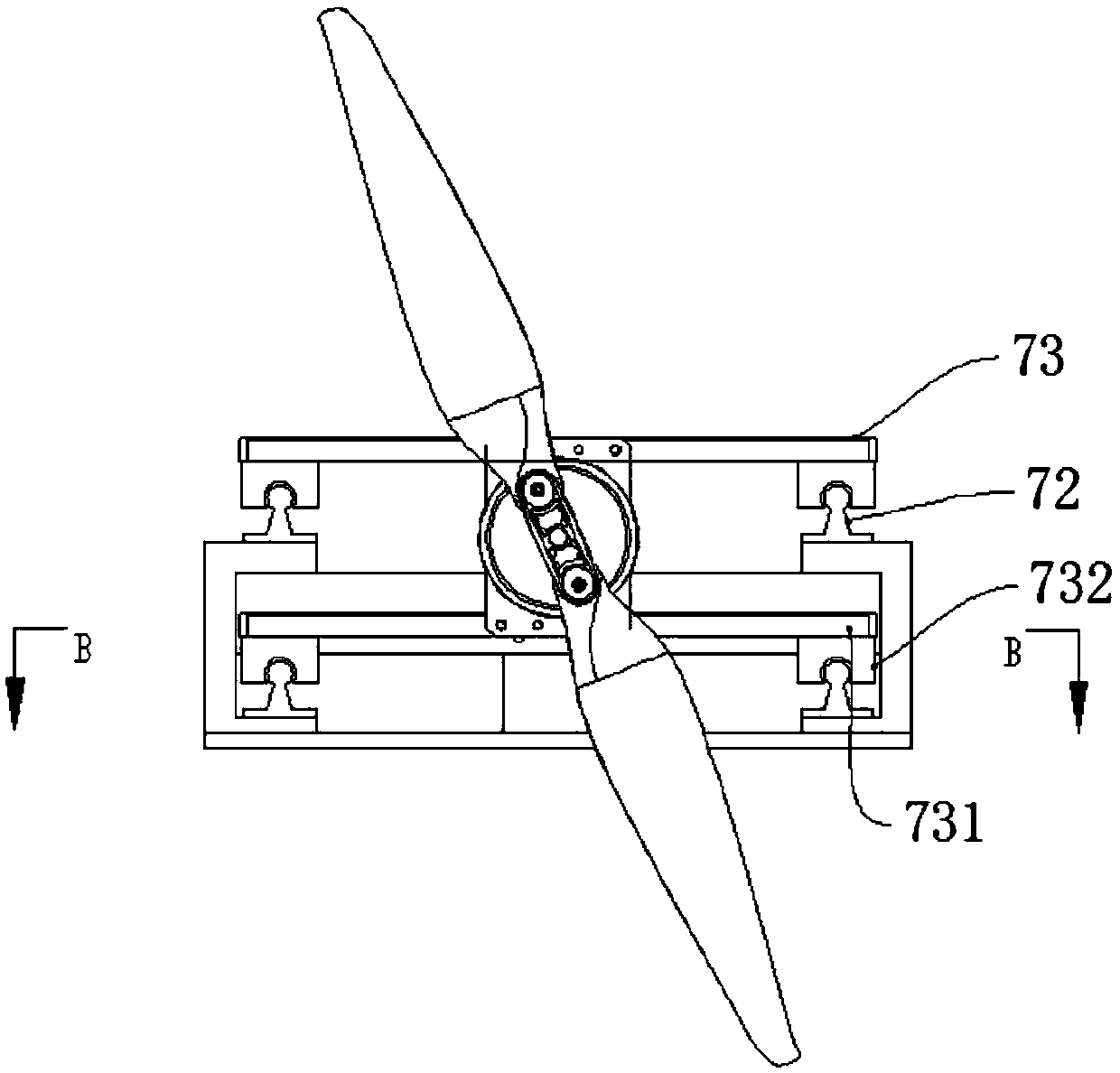

[0029] Such as figure 1 and figure 2 As shown, a propeller test device includes a propeller 1 and a motor 2 arranged at the rear end of the propeller 1 to provide rotational power for the propeller 1. The motor 2 is fixed on the motor base 3, and also includes a mounting frame 7 and is arranged on the mounting frame 7. The tension sensor 4 used to measure the tension parameter, the torque sensor 5 used to measure the torsion parameter, and the shock sensor 6 passing through one end of the mounting frame 7 and fixed on the motor base 3 for measuring the vibration parameter, the tension sensor 4, the torsion force The sensor 5 and the vibration sensor 6 respectively transmit the measured parameters to the display screen 84 arranged on one side of the installation frame 7 via wires.

[0030] In the prior art, the propeller testing machine is generally a single-function device. When testing the motion parameters of the propeller, generally only one of the parameters can be teste...

Embodiment 2

[0039] The structure of this embodiment is basically the same as the structure of Embodiment 1, and the similarities will not be repeated. The difference is that: Figure 7 , Figure 8 As shown, the propeller testing machine is arranged in the wind tunnel device 8, the wind tunnel device 8 includes a box body 81 and a wind tunnel 82 arranged in the box body 81 for testing the performance of the propeller 1, and two horizontally arranged in the wind tunnel 82 for The supporting beam 83 supporting the fixed installation frame 7 is provided with a display screen 84 for reflecting test parameters on one side of the box body 81, and a transformer cover 85 for installing a transformer is provided on the upper side of the box body 81, so that the gas can be studied through the wind tunnel device 8. Flow and its interaction with the propeller 1, in order to understand the aerodynamic characteristics of the actual propeller 1, the experimental conditions can be controlled more accurate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com