Hotpot condiment processing technique and device

A technology of hot pot bottom material and processing technology, which is applied in the direction of food science, etc., can solve the problems of low spicy and fresh flavor components, lack of spicy and fresh flavor, and cannot meet individual requirements, etc., and achieve the effect of bright red soup and long aftertaste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The hot pot bottom material processing technology of this embodiment adopts the "negative pressure extraction and concentration method" to produce the hot pot bottom material. In the still, the reaction kettle is vacuumed by negative pressure vacuum equipment, so that the raw materials of the hot pot bottom material are continuously rolled and rotated in the negative pressure vacuum to obtain the hot pot bottom material. During processing, the temperature in the reaction kettle is controlled at 120°C-150°C ℃, can quickly extract the spicy and fresh flavor in the hot pot bottom, and extract more than 80% of the spicy and fresh flavor; the processing time is 30-50 minutes, and the hot pot bottom material can be quickly and fully dissolved during the processing; the whole The system carries out industrialized production on the basis of the Chinese process, which includes a circulating water pump, a flask, a vacuum condenser, a cold water pump and an electric heating jacket....

Embodiment 2

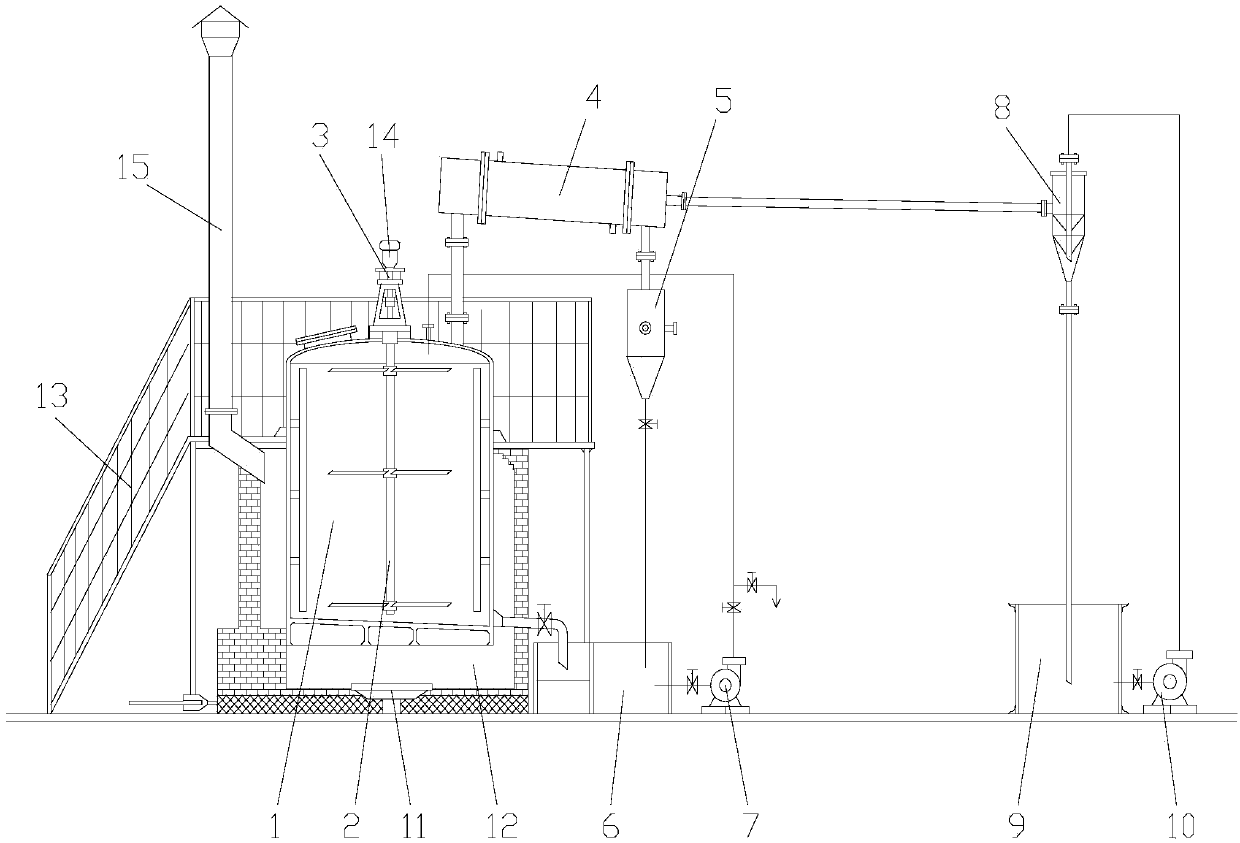

[0029] Such as figure 1Shown: the chafing dish bottom material processing equipment of the present embodiment, comprises the direct-fire heating cooking reactor 1 that is installed in combustion furnace 12 and is used to carry out the vacuumizing assembly that described direct-fire heating cooking reactor 1 is vacuumized; The bottom of the combustion furnace 12 is provided with a natural gas burner 11, and the side wall of the combustion furnace 12 is equipped with a flue gas discharge tube 15. The upper part of 1 is exposed above the combustion furnace 12, and the top of the direct-fire heating and cooking reaction kettle 1 is provided with a filling port, and the direct-fire heating and cooking reaction kettle 1 is provided with a propulsive stirring paddle 2; the direct-fire heating and cooking reaction kettle 1 The top of the furnace is equipped with a drive motor 14 and a reducer 3 for driving the propulsion type stirring paddle 2; the top of the combustion furnace 12 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com