Circuit board and shell seamless glue injection equipment and method

A technology for circuit boards and shells, which is applied in the field of seamless glue injection equipment for circuit boards and shells, can solve the problems of high cost, large floor space, and large volume of glue dispensers. Back overflow glue, high production efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

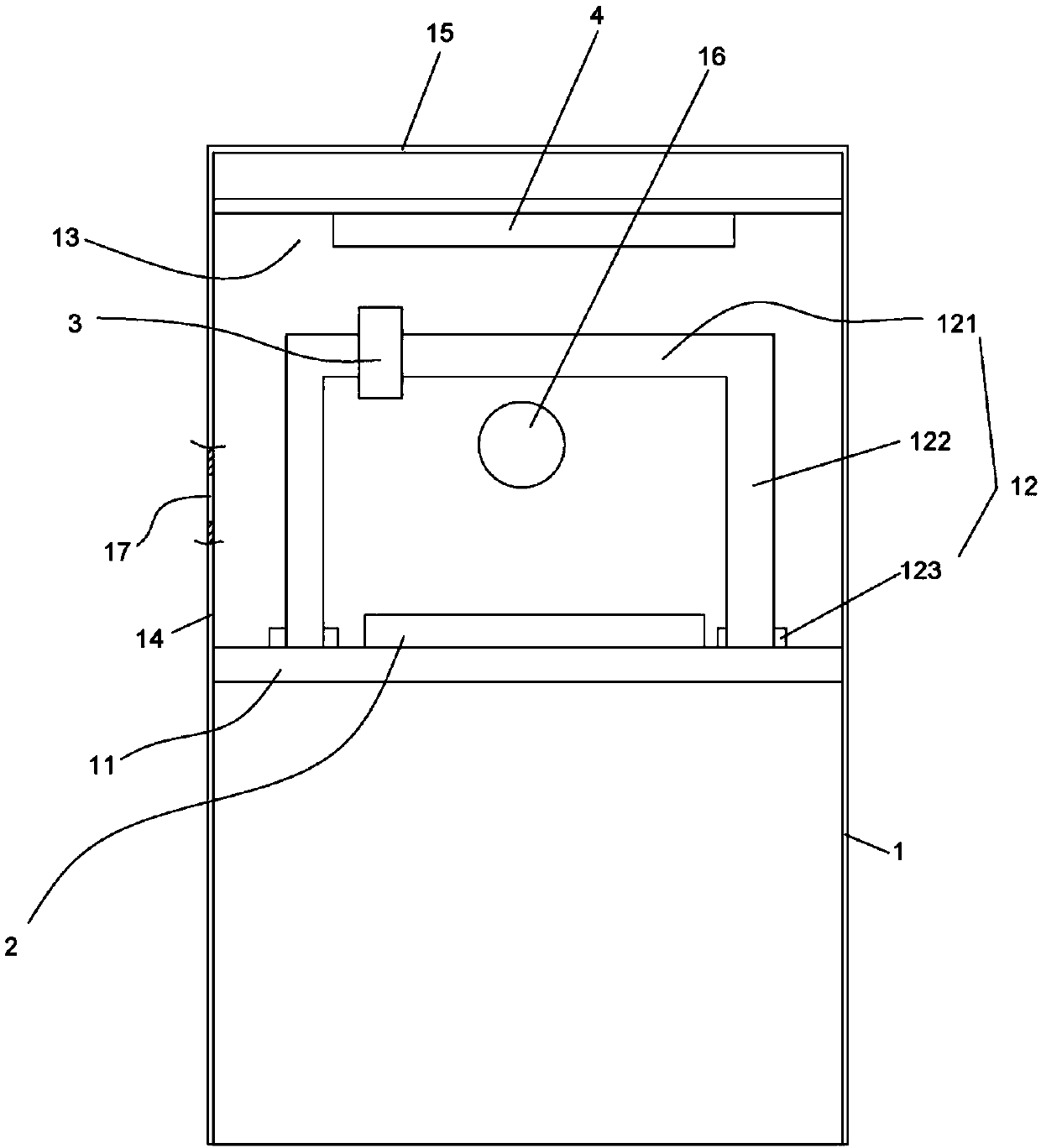

[0037] like figure 1 As shown, a circuit board and shell seamless glue injection equipment includes a placement fixture 2, a dispensing frame 1 that provides support for the placement fixture 2, and a dispensing head 3;

[0038] The placement jig 2 is used to support the combined circuit board and shell;

[0039] The dispensing head 3 is arranged above the placing jig 2 for dispensing the circuit board and the shell;

[0040] It also includes a controller, the controller is connected to the dispensing head 3, and controls the corresponding dispensing head 3 to perform the dispensing action according to the dispensing position and the parameters of the coding equipment input by the user;

[0041] Preferably, it also includes a sealing inspection device 4 arranged above the placing jig 2 . The above referred to in this embodiment is not limited to directly above.

[0042] After the dispensing is completed, the sealing inspection is an indispensable process. The sealing of the...

Embodiment 2

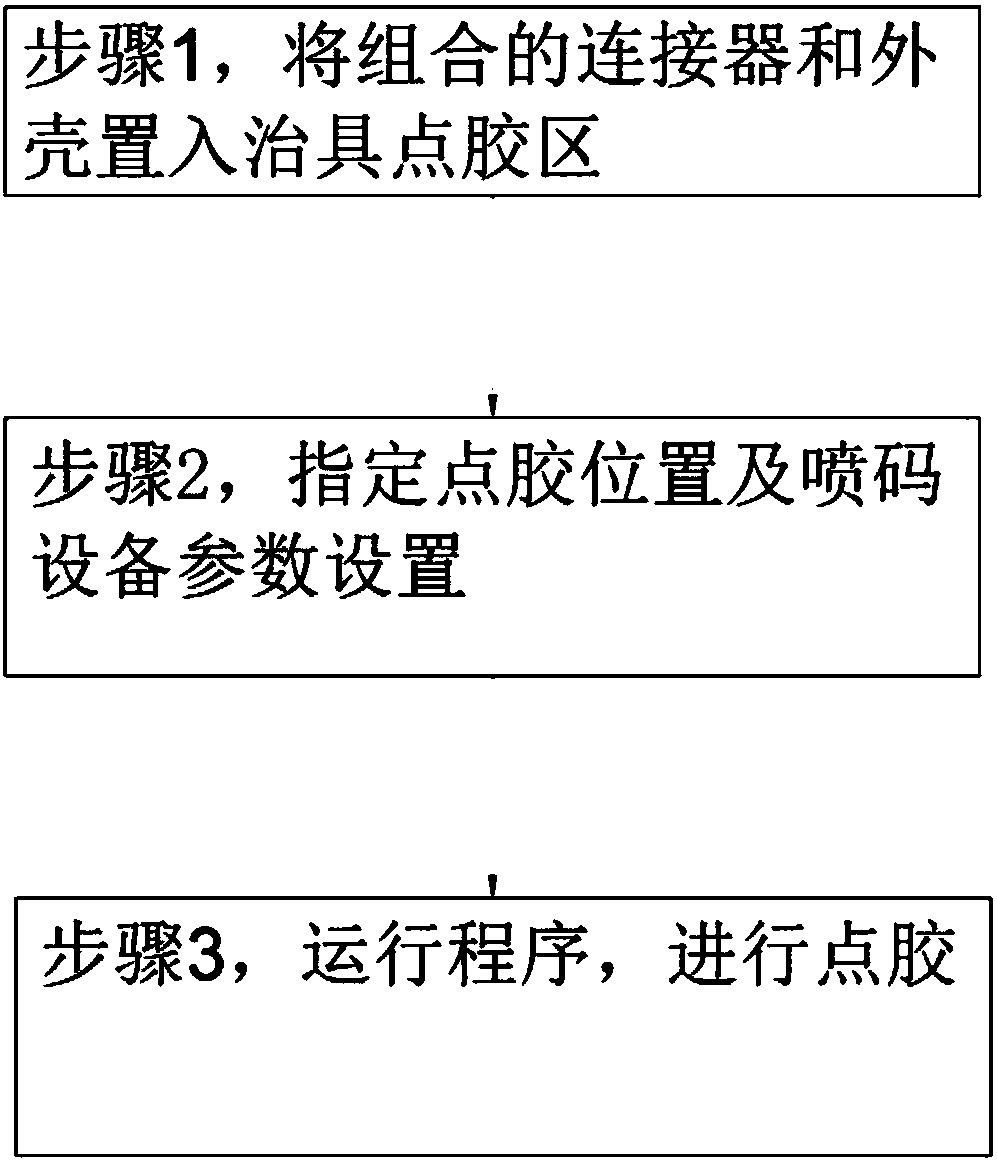

[0059] like figure 2 As shown, a method for seamless glue injection between the circuit board and the shell, the following steps are performed:

[0060] Step 1, put the circuit board and the shell into the dispensing area of the fixture;

[0061] In this step, the infrared sensor can be used to determine whether the circuit board and the casing are accurately placed in the dispensing area. If not, it will affect the starting position and end position of dispensing, resulting in a lack of product quality. In addition , The infrared sensor is simple, direct and effective, and it is a common product on the market with a low price.

[0062] Step 2, specify the dispensing position and the parameter setting of the inkjet equipment;

[0063] In this embodiment, editing the preset program is embodied in specifying the dispensing position and the parameter setting of the inkjet equipment, selecting the corresponding dispensing head, and moving to the program setting position for d...

Embodiment 3

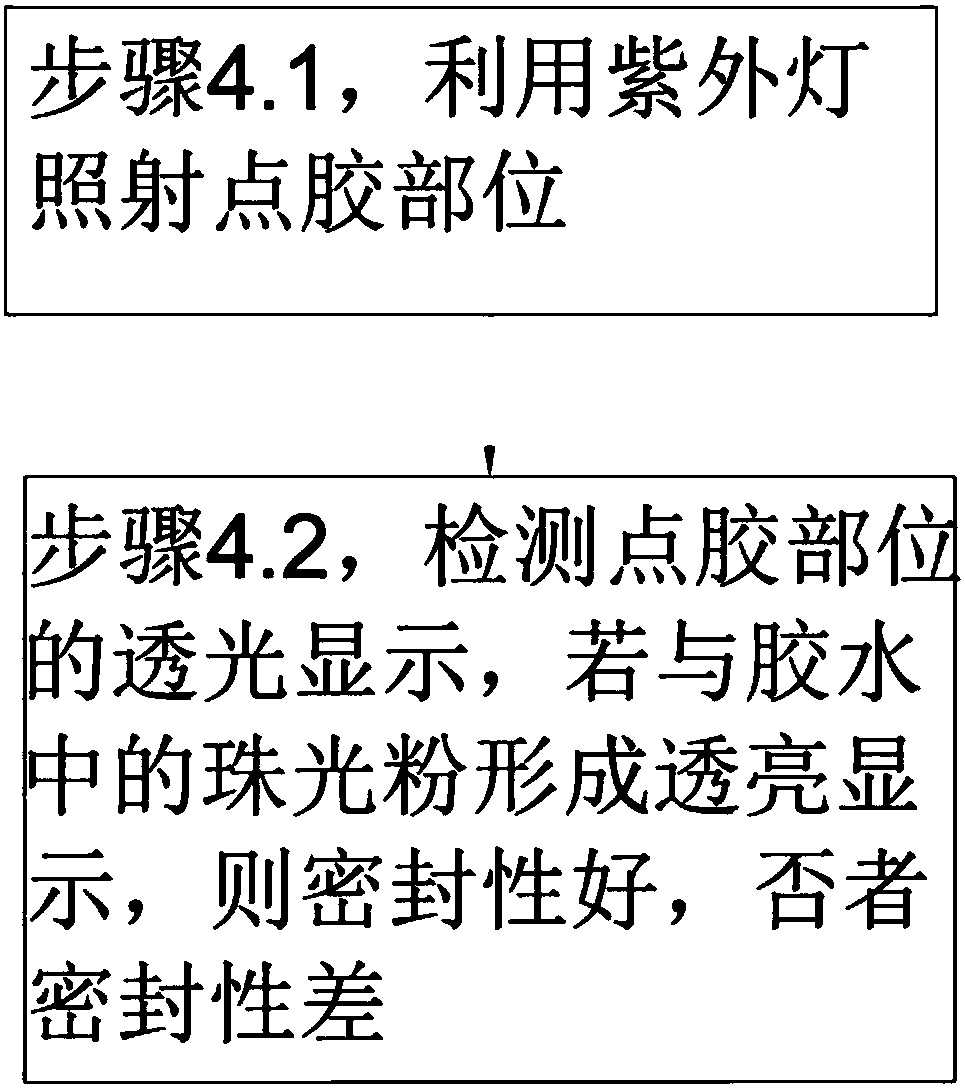

[0078] In step 4.2, when the detected tightness is poor, re-dispensing step 5 is performed.

[0079] The glue dispensing step 5 can again dispens glue to the circuit board and the shell, and convert the secondary products into qualified products.

[0080] Preferably, the re-dispensing step 5 specifically includes:

[0081] Step 5.1, put the circuit board and the shell into the dispensing area of the fixture again;

[0082] Step 5.2, infrared scanning and acquisition of defect starting position and defect length;

[0083] Step 5.3, manually adjust the dispensing head, and move the dispensing head to the starting position of the defect;

[0084] Step 5.4, setting the dispensing end point position according to the defect length;

[0085] Step 5.5, start the program to dispense again.

[0086] All the other are with embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com