Device for rapidly positioning manual connecting milling head on numerical control machine tool

A technology for positioning devices and CNC machine tools, which is applied to positioning devices, machine tool parts, metal processing machinery parts, etc., can solve problems such as low cost, complex structure of connecting devices, and difficult positioning and docking, so as to reduce labor intensity and improve docking efficiency , to avoid the effect of manual positioning process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

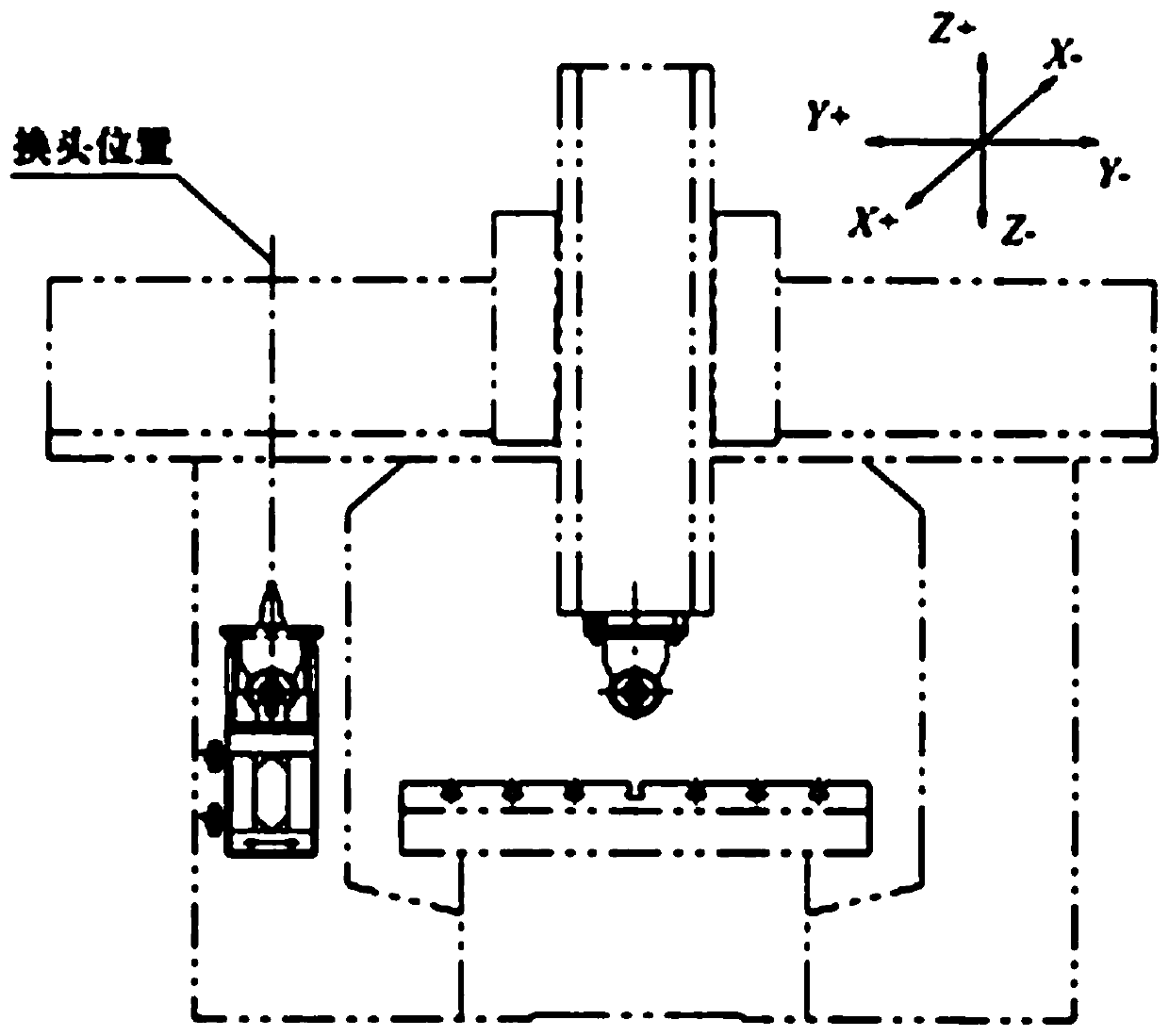

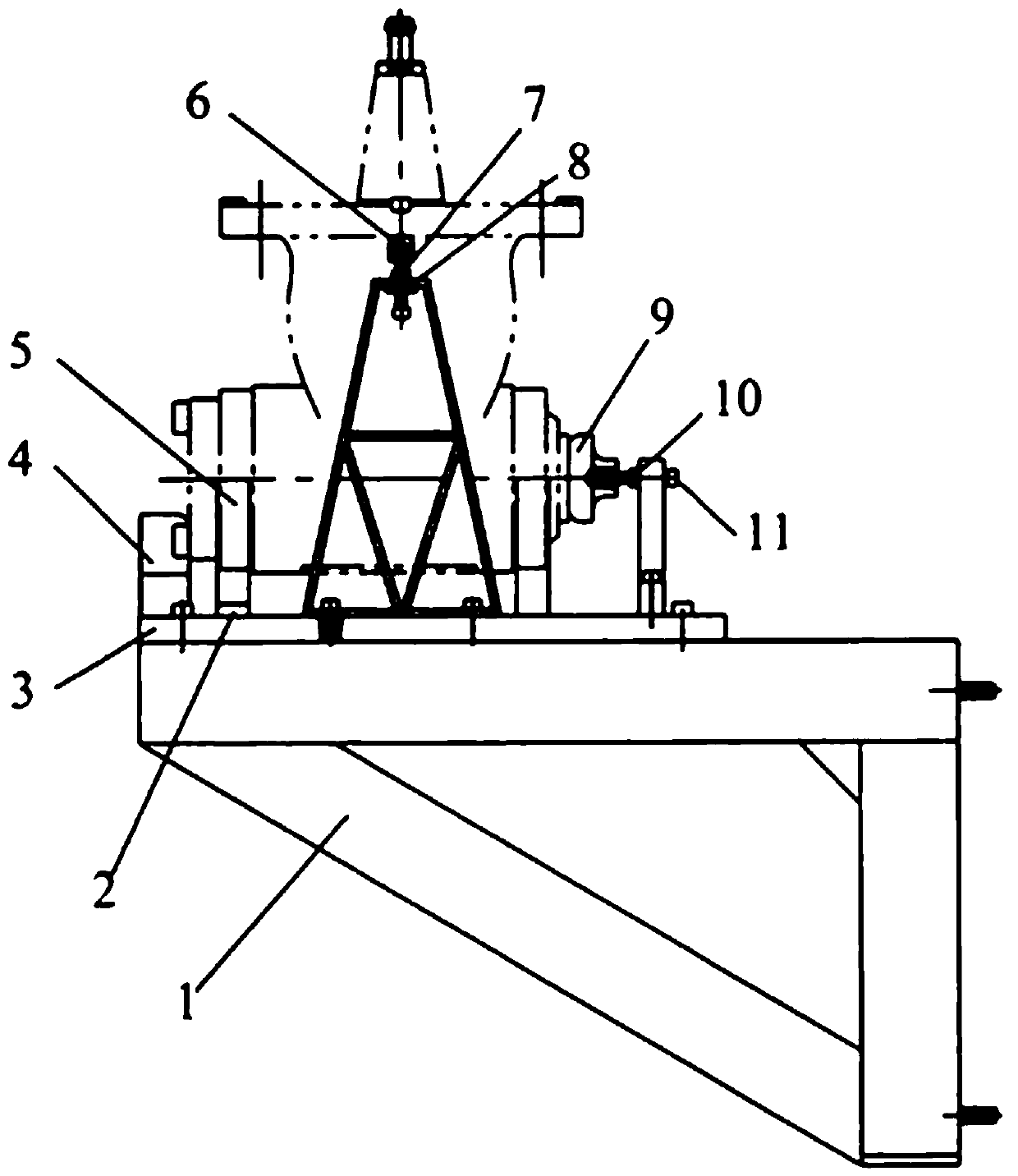

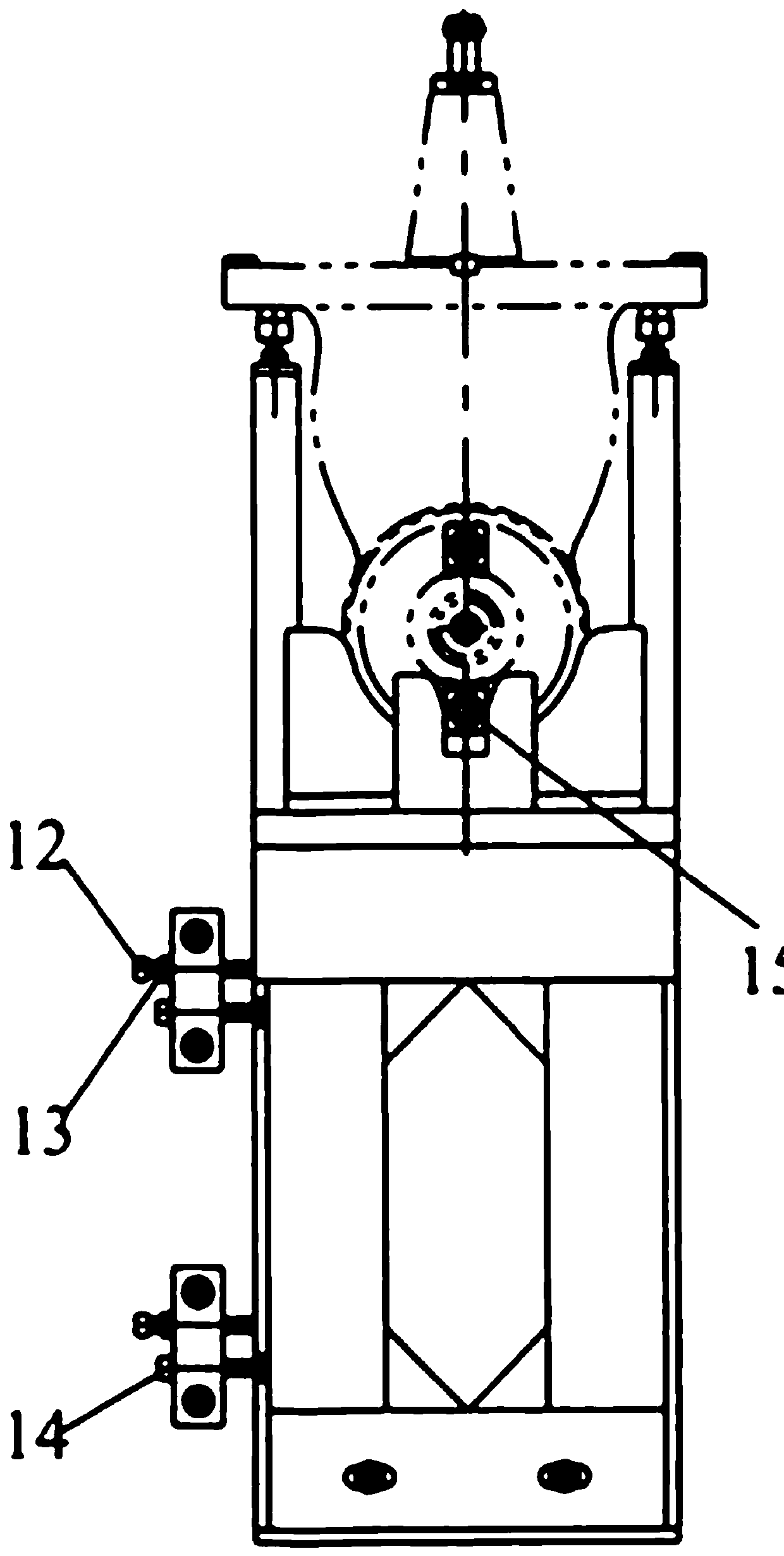

[0015] On the left column of the machine tool such as figure 1 Installed in the position shown image 3 The manual connection of the right-angle milling head rapid positioning device shown in the figure, through the CNC system command of the machine tool, in the y+ direction such as figure 1 Set the head change point at the position shown, move the machine tool ram along the y+ direction to drive the milling head to the head change point, use the hand-held control unit to slowly move the ram down until the milling head enters the range of the positioning device, and push it by adjusting the upper and lower 12 or 14 screws Or pull the support 1 to move along the y direction, so that the milling head is in the middle of the support. Set the directional stop position of the machine tool spindle when the head is changed through the command of the numerical control system, and the end face key 15 at the output end of the milling head can be controlled at the position shown in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com