Internal polishing device for kettle body

A polishing device and pot body technology, which is applied in the direction of grinding drive device, grinding/polishing equipment, surface polishing machine tool, etc., can solve the problems of complex structure, high cost and inconvenient promotion of polishing equipment, and achieve good practical application and Promotional value, convenient and flexible operation, simple and exquisite structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

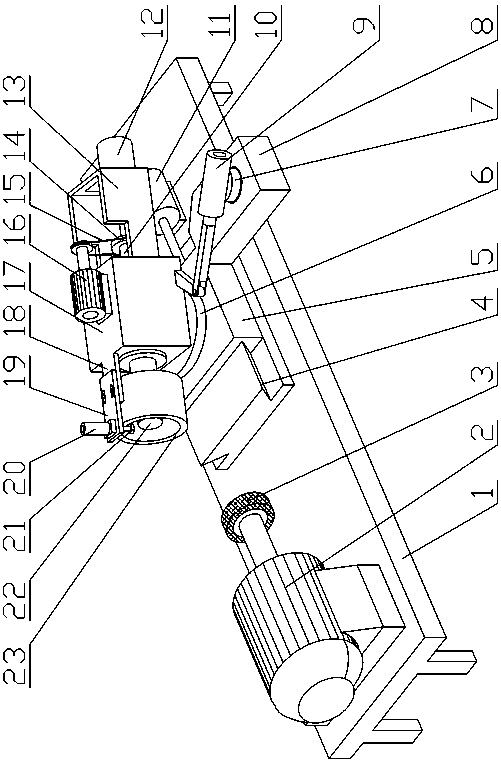

[0015] see figure 1 and figure 2 , the present invention is a polishing device inside a kettle body, which has a base 1, a grinding motor 2 is installed on one side of the base, and a polishing wheel 3 is installed on the output shaft of the grinding motor; The kettle clamping and feeding device is arranged, and the kettle clamping and feeding device has a slide rail 4 installed on the base, and the slide rail is equipped with a slider 5, and the slider passes through the feeding device arranged at the rear of the slide rail. Cylinder 11 is driven to realize forward and backward, a rotating disk 6 is arranged in the middle of the upper part of the slider, and a mounting box 17 is arranged on the rotating disk. Clamp 23, the front end of the kettle body clamp is open and rotates with the hollow shaft. The rear end outer ring of the hollow shaft is provided with a sprocket 14, and the sprocket is connected to the sprocket motor 16 installed on the top of the casing by a chain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com