Packaging paper box edge-folding device and machining method thereof

A technology of a hemming device and a processing method, which is applied in the field of hemming devices for packaging cartons, can solve the problems of increased cost, cumbersome methods, products cannot be smoothly placed in cartons, etc., and achieves the effect of improving production efficiency and reducing multiple processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings.

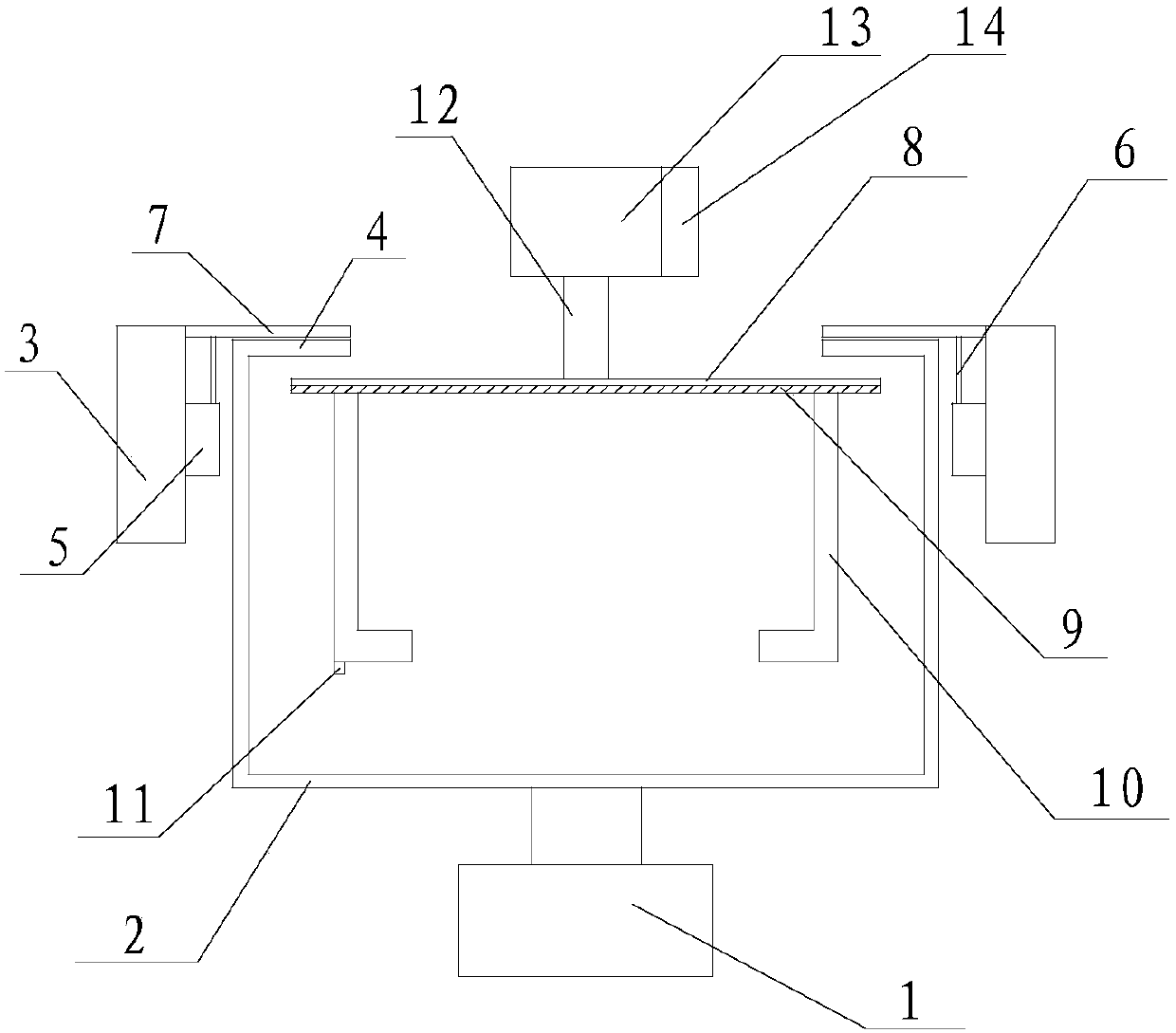

[0019] Such as figure 1 As shown, a packaging carton hemming device and its processing method of the present invention include a cylinder 1, a bracket 2, and a support frame 3. The cylinder 1 is fixedly connected to the bracket 2, and the two ends of the bracket 2 are symmetrically arranged on the top. There is a U-shaped plate 4, the support frame 3 is symmetrically arranged on the outside of the bracket 2, the inside of the support frame 3 is provided with a hydraulic cylinder 5, and the hydraulic cylinder 5 is connected to a hydraulic strut 6, and the hydraulic strut 6 is connected to the pressing plate 7, a baffle plate 8 is provided directly above the bracket 2, and a guide rail 9 is provided at the lower end of the baffle plate 8, and two push plates 10 matched with it are provided on the guide rail 9, and the A pressure sensor 11 is provided at the bottom of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com