Conveying belt system capable of performing sorting

A technology for conveyor belts and main conveyor belts, which is applied to conveyor objects, conveyor control devices, transportation and packaging, etc. It can solve problems such as low accuracy of manual identification, failure of automatic completion of the conveyor system, and operator fatigue, and achieve The effect of identifying the simple sorting structure and facilitating the automatic operation of cargo sorting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

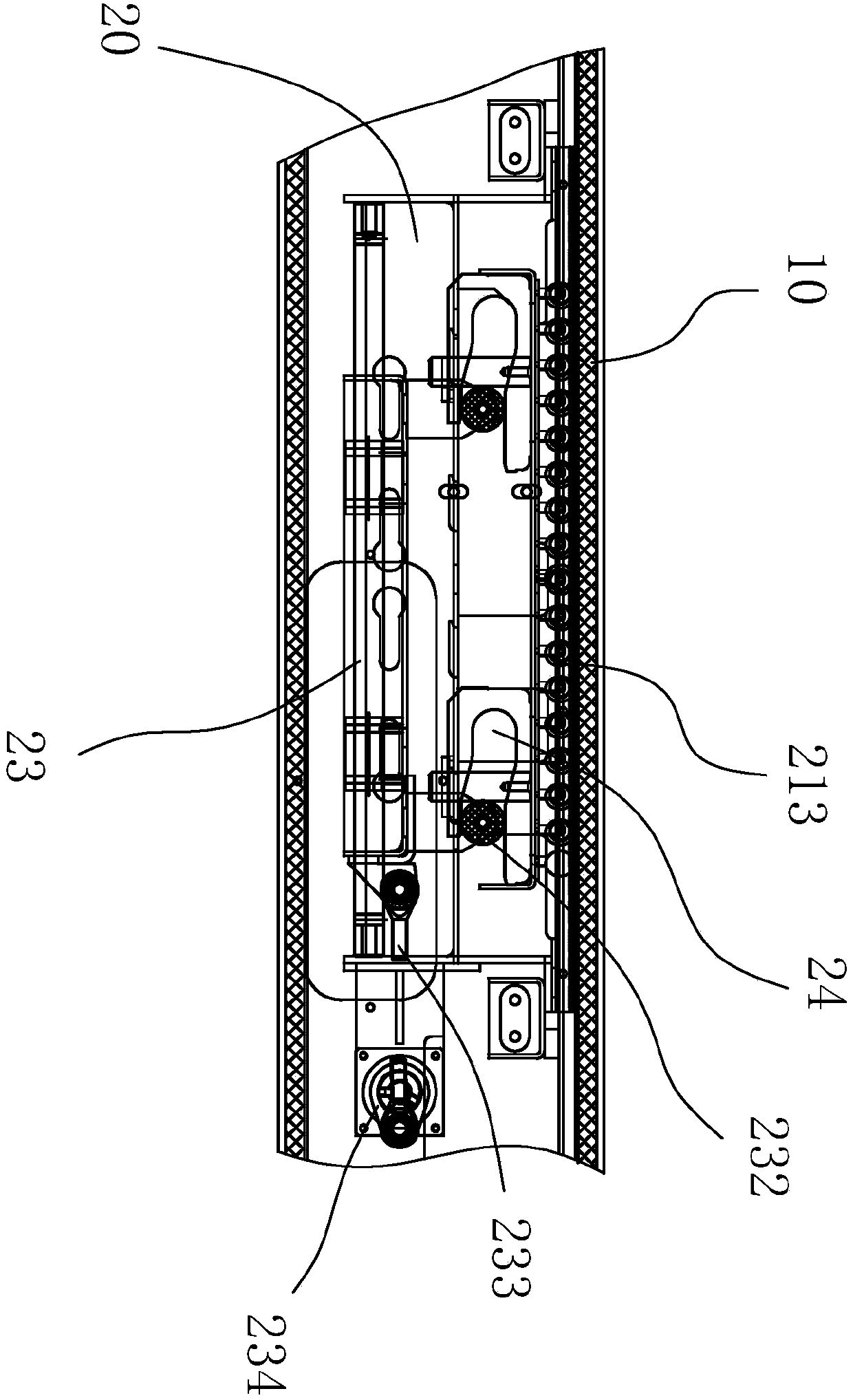

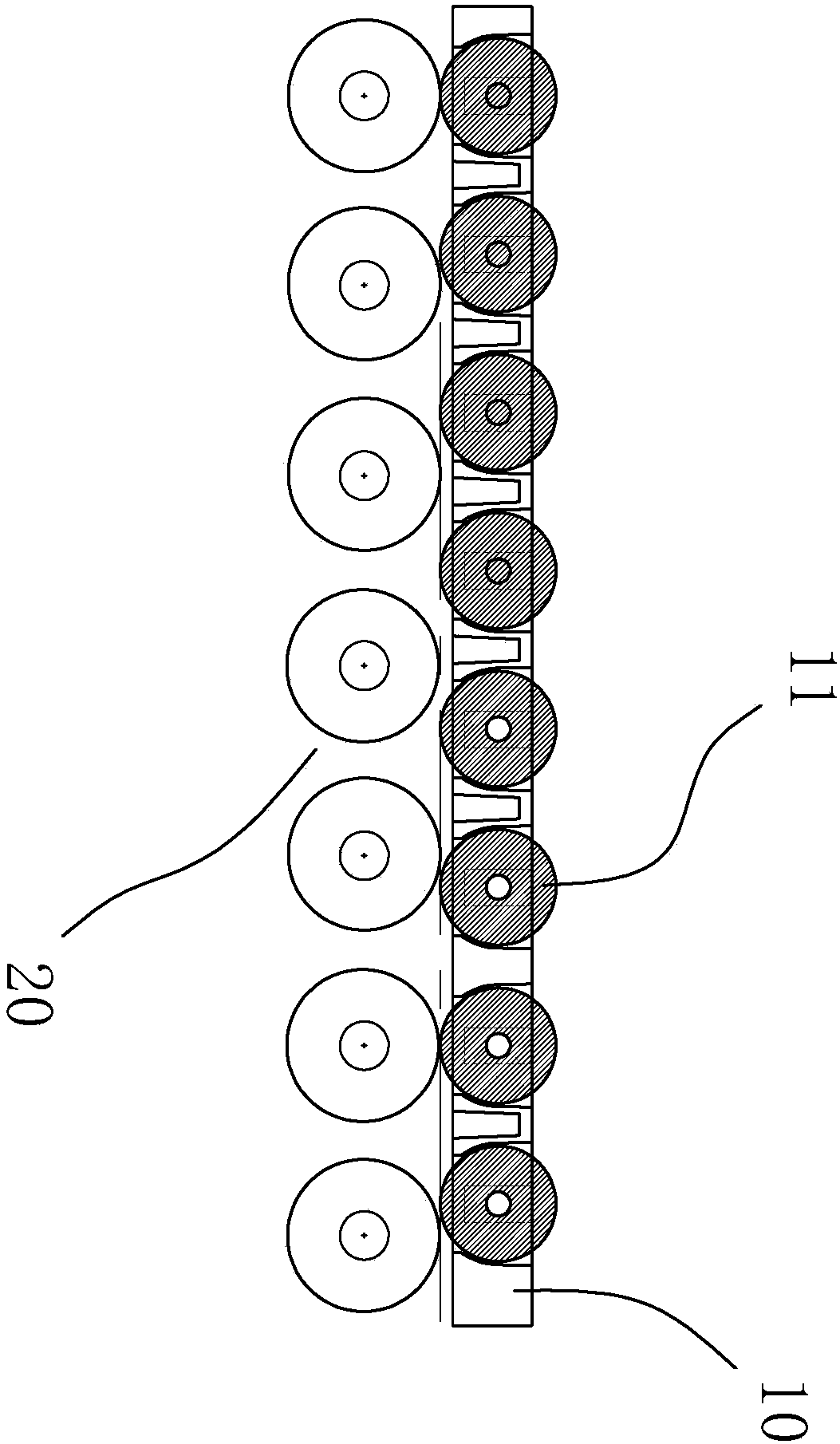

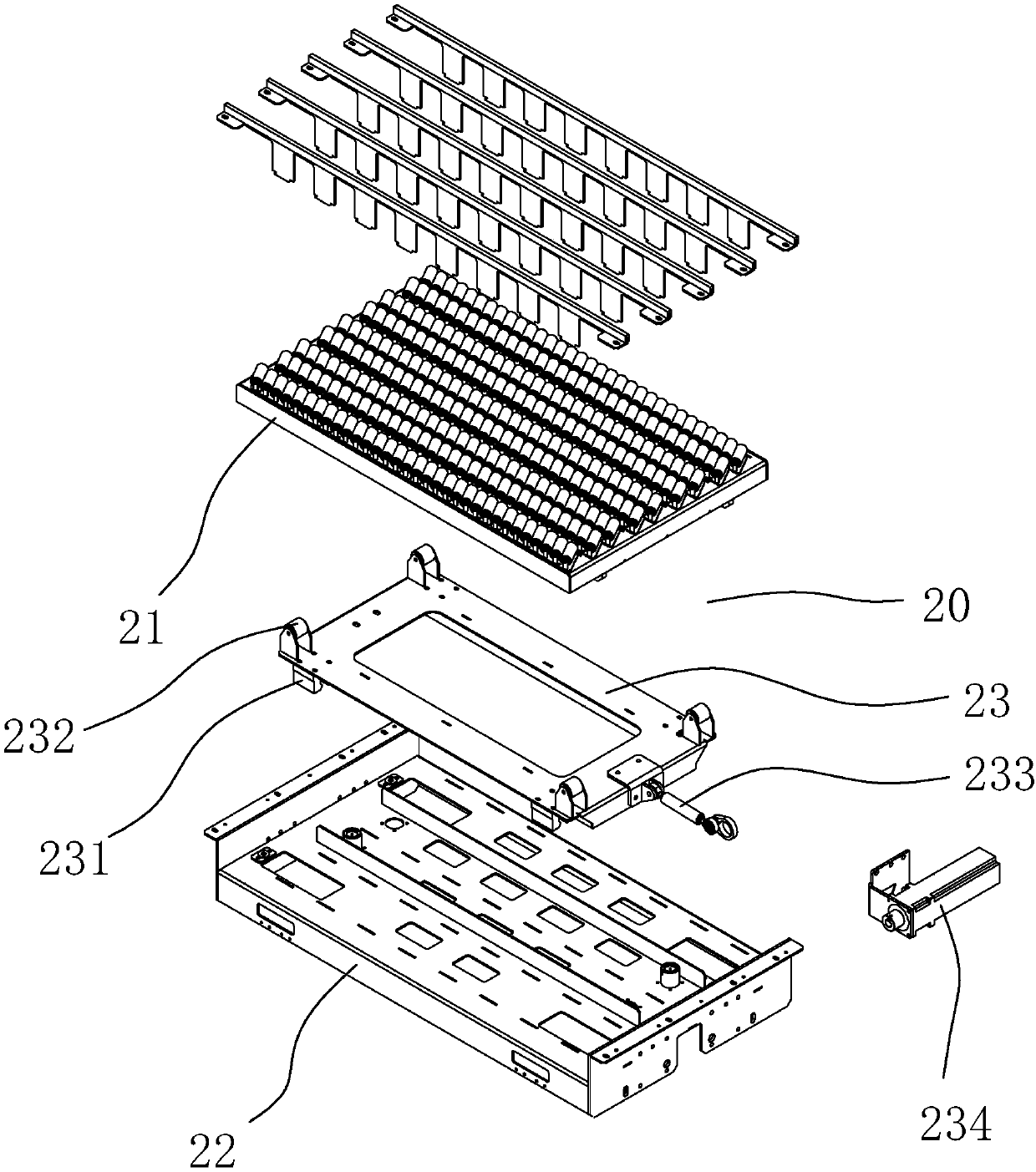

[0026] refer to Figure 1 to Figure 7 , the present invention is a conveyor belt system capable of sorting, comprising a main conveyor belt 10 and a sorting mechanism 20 positioned below the main conveyor belt 10, the main conveyor belt 10 is provided with a number of conveying balls 11, and each conveying ball 11 winds The rotating shaft of the conveying balls perpendicular to the conveying direction of the main conveyor belt 10 rotates. The sorting mechanism 20 is respectively provided with a number of sorting balls 213 and parallel sorting ball rotating shafts. Each sorting ball rotating shaft is arranged obliquely along the conveying direction. The sorting mechanism 20 is arranged horizontally so that the top of the sorting ball 213 is in contact with the bottom of the conveying ball 11, and a jacking mechanism that can drive the sorting mechanism 20 up and down to separate the sorting ball 213 from the conveying ball 11 is also provided.

[0027] In this conveyor belt sys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com