Non-contact continuous and high-precision length detecting and sorting device

A non-contact, sorting device technology, applied in sorting and other directions, can solve problems such as affecting the transmission speed of products, and achieve the effects of high work efficiency, energy saving and cost saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

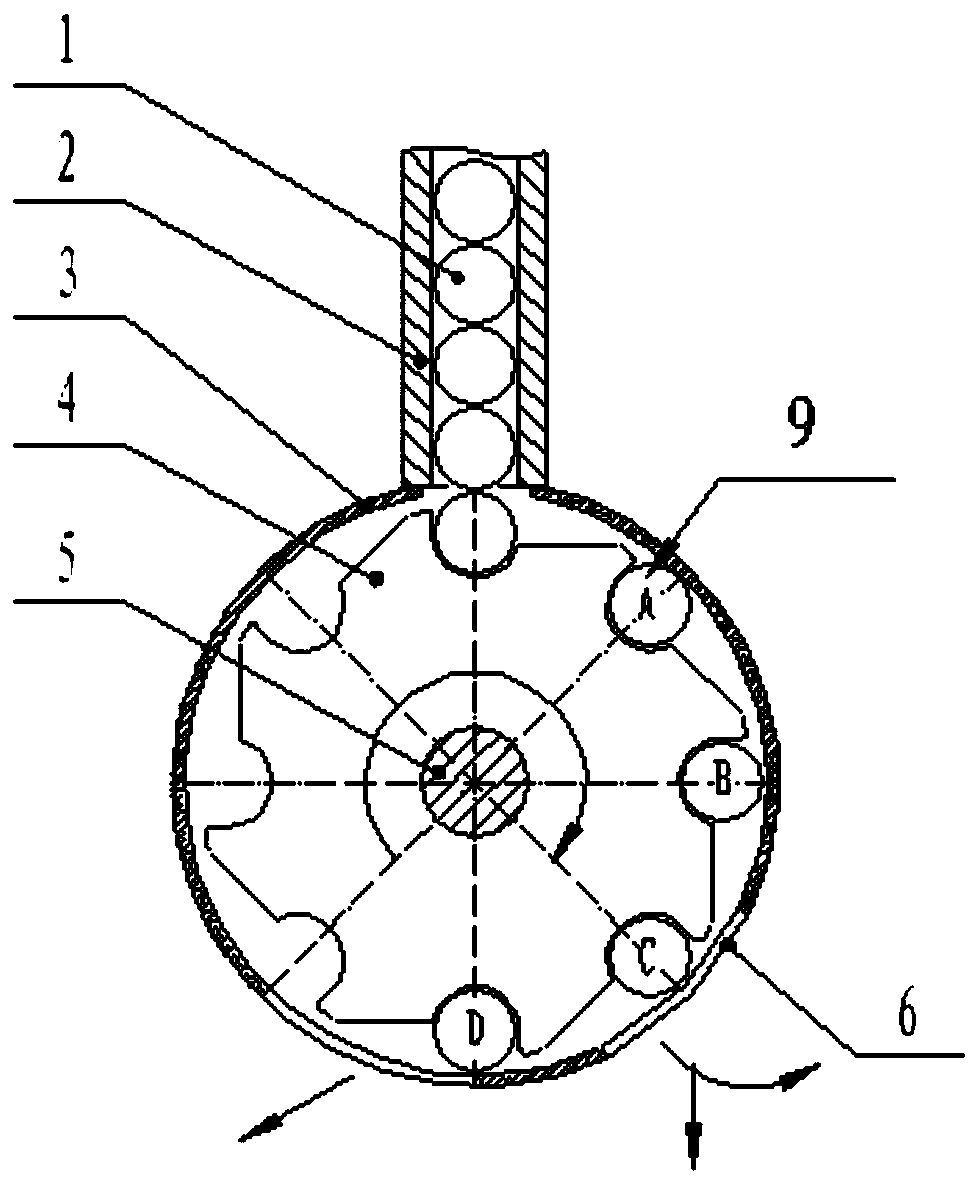

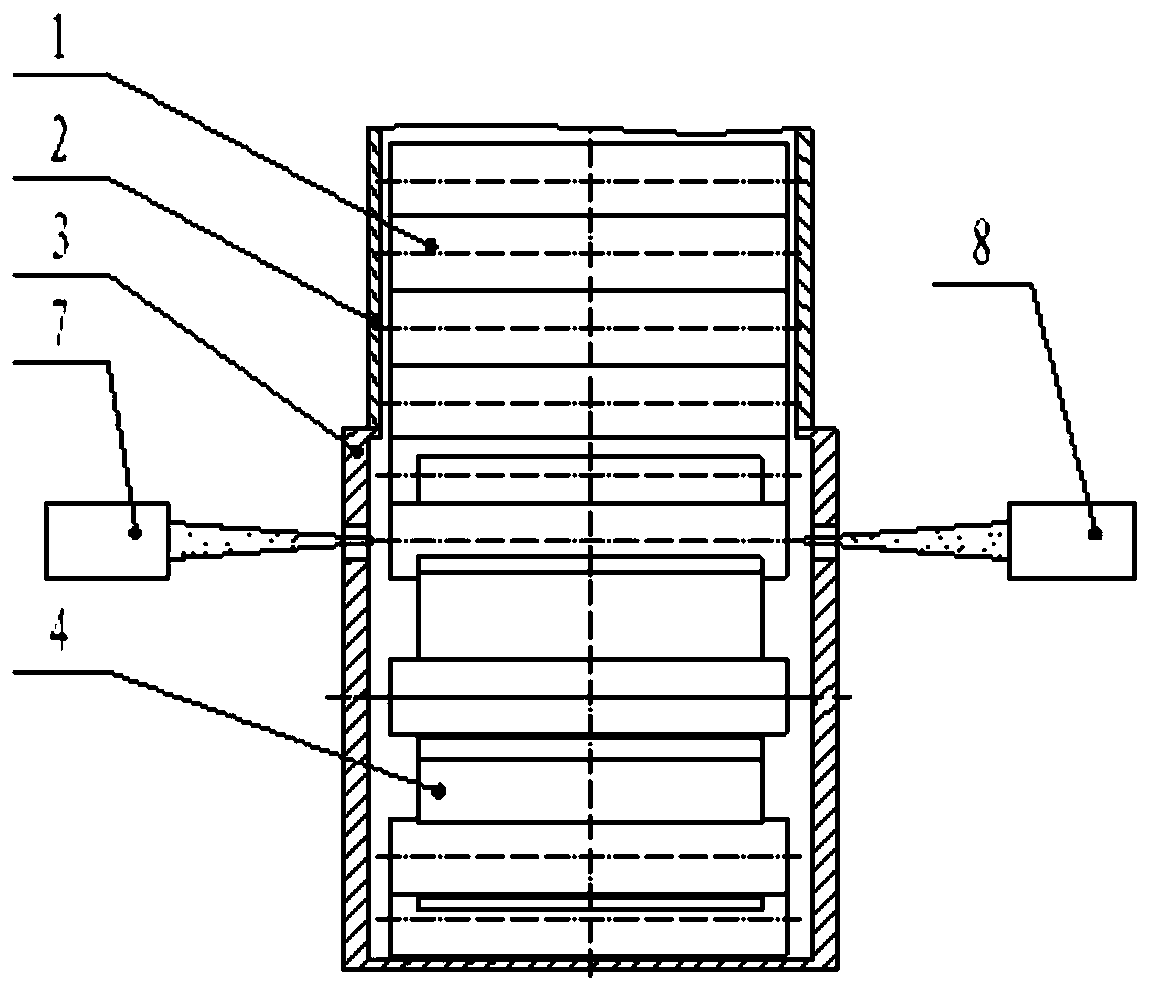

[0026] A non-contact continuous high-precision length detection and sorting device includes: feeding chute 2, positioning retainer 3, positioning and distributing ratchet 4, ratchet shaft 5, sorting valve 6, left laser rangefinder 7, The right laser rangefinder 8 and detection point 9. The feed chute 2 and the positioning retainer 3 are fixed; the positioning retainer 3, the positioning distribution ratchet 4 and the ratchet shaft 5 are all cylindrical, and the axes coincide; the feed chute 2 is connected to the peripheral wall of the positioning retainer 3 The relative position of the ratchet shaft 5 and the positioning and distributing ratchet 4 is fixed. The positioning and distributing ratchet 4 rotates with the ratchet shaft 5. When the ratchet shaft 5 drives the positioning and distributing ratchet 4 to rotate clockwise, the feed chute 2 After the product 1 inside enters the cylindrical groove on the positioning and distributing ratchet 4, the position is limited by the ...

Embodiment 2

[0028] The left laser range finder 7 and the right laser range finder 8 rely on laser irradiation on the two end faces of the product for non-contact detection, and the measurement accuracy can reach up to 0.001mm. The specific steps are: use a standard product with an actual length of X±0.005mm for length calibration, the left laser range finder 7 and the right laser range finder 8 irradiate the two end faces of the standard product to obtain two values Y and Z, calculate Y—Z=M, M is the relative length of the detection, at this time we set M as X; when the ordinary product moves to the detection position, the left laser range finder 7 and the right laser range finder 8 irradiate the two product end faces to obtain The two values are Y1 and Z1. The system automatically calculates Y1—Z1=M1, and then calculates the value of M—M1 as t1. At this time, the actual length of the product is X+t1. By analogy, the actual length of the rest of the products can be measured. length. ...

Embodiment 3

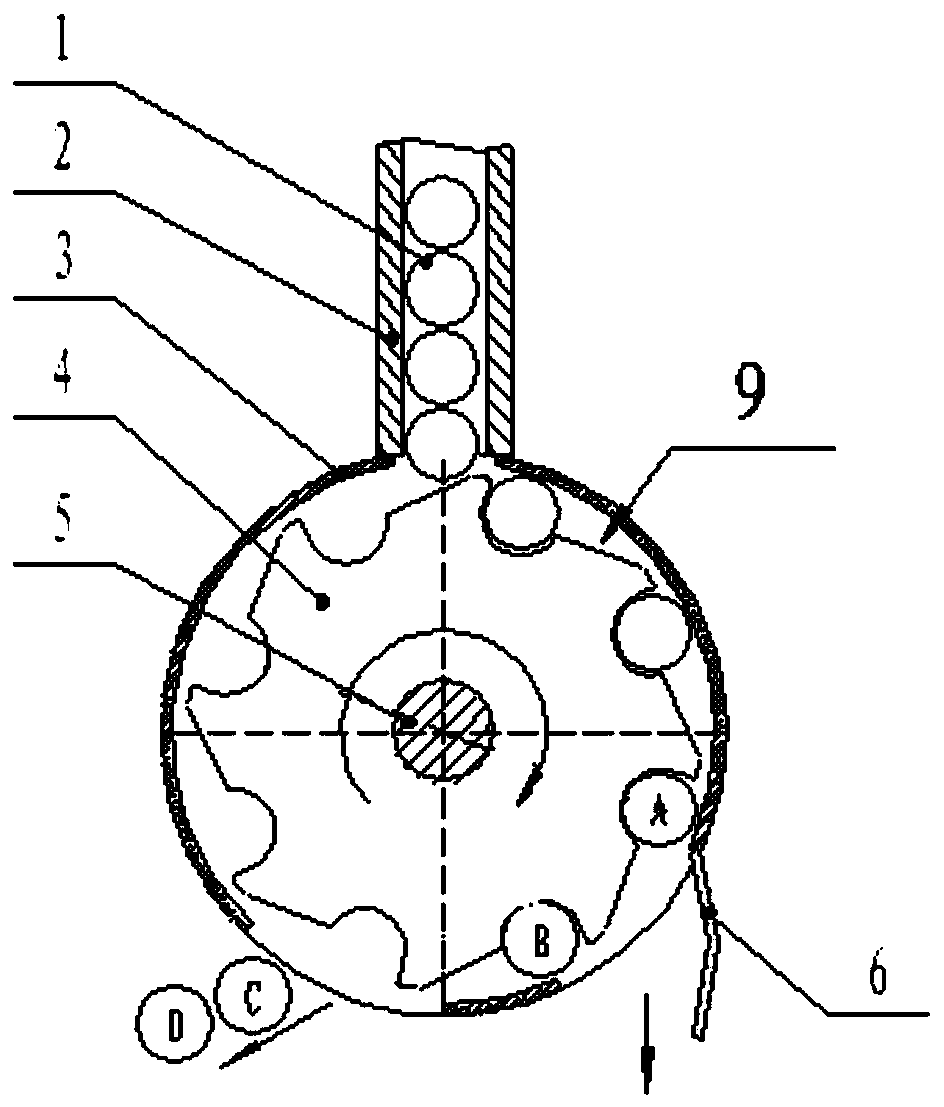

[0031] The product A enters the positioning and distributing ratchet 4 of the inner ring of the positioning retainer 3 through the feeding chute 2, and the ratchet shaft 5 is driven to rotate by the gravity of the product A itself, and when it passes the detection position, the left laser range finder 7 and the right laser range finder The distance meter 8 detects the length of both ends of the product A, and compares the reference standard value range. Product A continues to move to the feed opening 6, such as image 3 As shown, when product A arrives at the 70-degree position shown in the lower end of the device, the sorting valve 6 rotates counterclockwise to the right and opens, and when the next qualified product reaches the 70-degree position of the device as shown in the figure, the sorting valve 6 turns to the left Turn counterclockwise to close. like Figure 4 As shown, after product A leaves the device through the sorting valve, product A with unqualified length le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com