Control method of automatic storage, sorting and loading system for unmanned aerial vehicle express delivery

A loading system and unmanned aerial vehicle technology, applied in storage devices, transportation and packaging, etc., can solve problems such as speed that cannot meet the requirements of rapid response to orders, low resource utilization efficiency, etc., to reduce labor costs and labor intensity, and improve operations. Efficiency, Control Precise Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

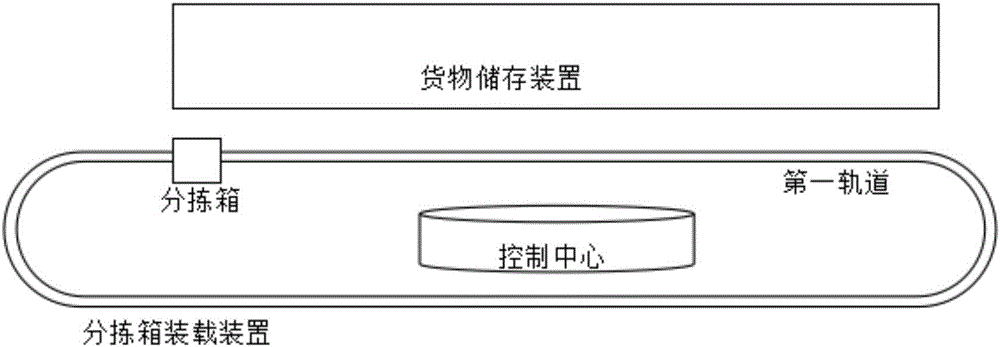

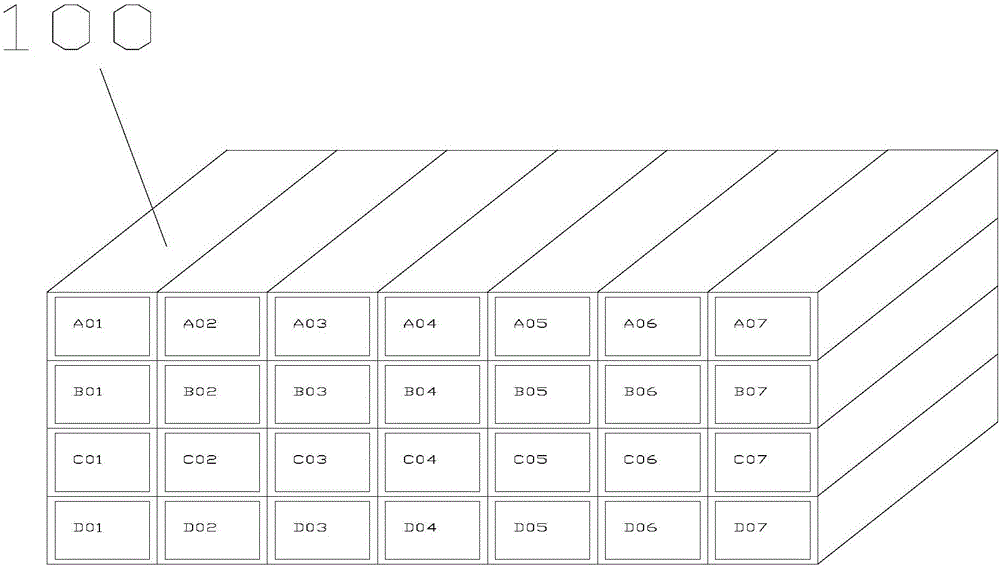

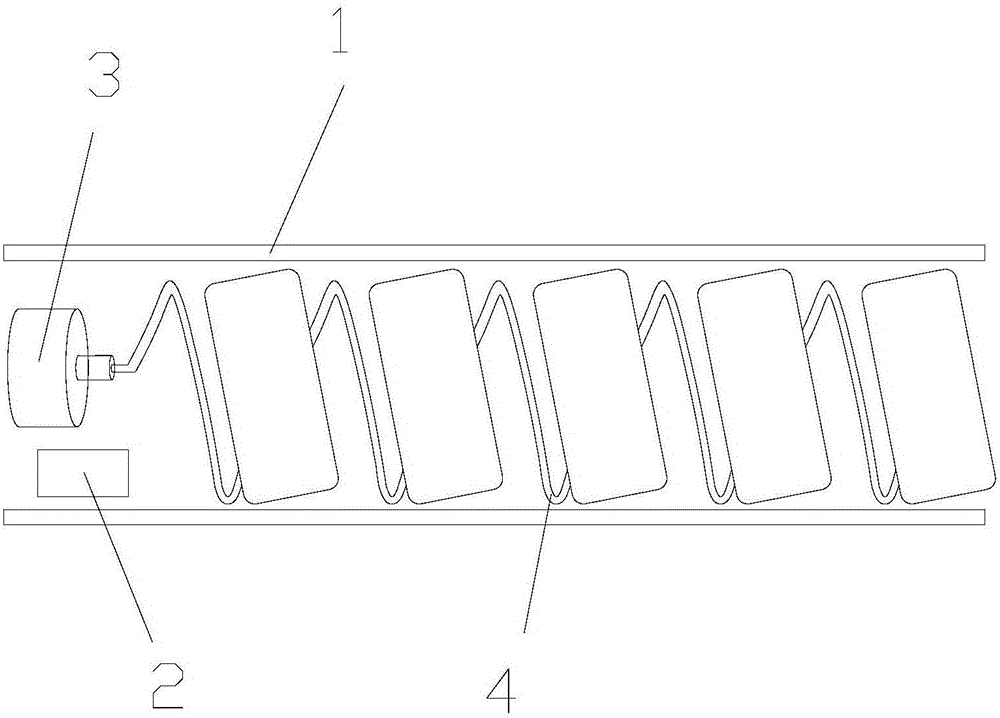

[0040] refer to figure 1 , an automated warehouse sorting and loading system for unmanned aerial vehicle express delivery, including a cargo storage device, a sorting box loading device, and a control center; the cargo storage device includes at least one storage unit, and the storage unit includes a warehouse body and a push mechanism; The front and rear ends of the body are open, and the warehouse body is a rectangular parallelepiped structure. The warehouse body includes a warehouse top plate, a warehouse body bottom plate and two warehouse body side plates. The stacking mechanism; the push mechanism includes a first servo motor and a transmission device, the first servo motor and the transmission device are installed in the bin body, and the output shaft of the first servo motor is connected to the power transmission device; the transmission device includes a screw rod, and one end of the screw rod is connected to the second The output shaft of a servo motor is connected, ...

Embodiment 2

[0051] refer to Figure 7 , a control method for an automated storage, sorting and loading system for unmanned aerial vehicle express delivery, comprising the following steps:

[0052] S1: The control center obtains order information and delivery instructions;

[0053] S2: The control center controls the box clamping device of the sorting box loading device to move the sorting box 92 or the drone cargo compartment 93 to the front end of the corresponding storage unit;

[0054] S3: the control center controls the storage unit to push out the frontmost item in the storage unit, and slides it into the sorting box 92 or the cargo compartment 93 of the drone;

[0055] S4: After the sorting box loading device receives the first cargo, the control center controls the box clamping device of the sorting box loading device to move the sorting box 92 or the drone cargo compartment 93 to the storage where the second cargo is located The front end of the unit's warehouse;

[0056] S5: R...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com