Static elimination brush structure for vacuum aluminum plating

A technology for vacuum aluminum plating and electrostatic removal, which can be used in vacuum evaporation plating, sputtering plating, ion implantation plating, etc. problems, to achieve the effect of improving the contact area of static electricity removal, good practicability, and improving quality and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

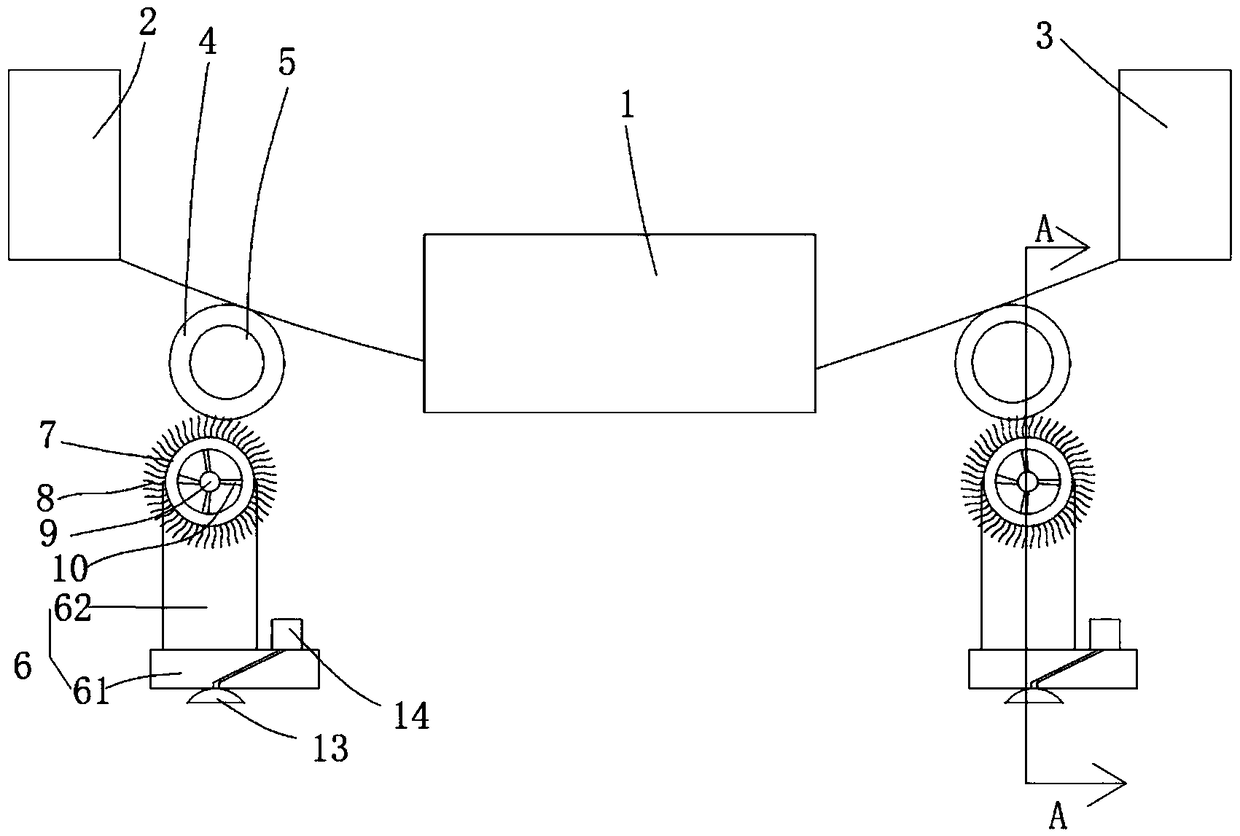

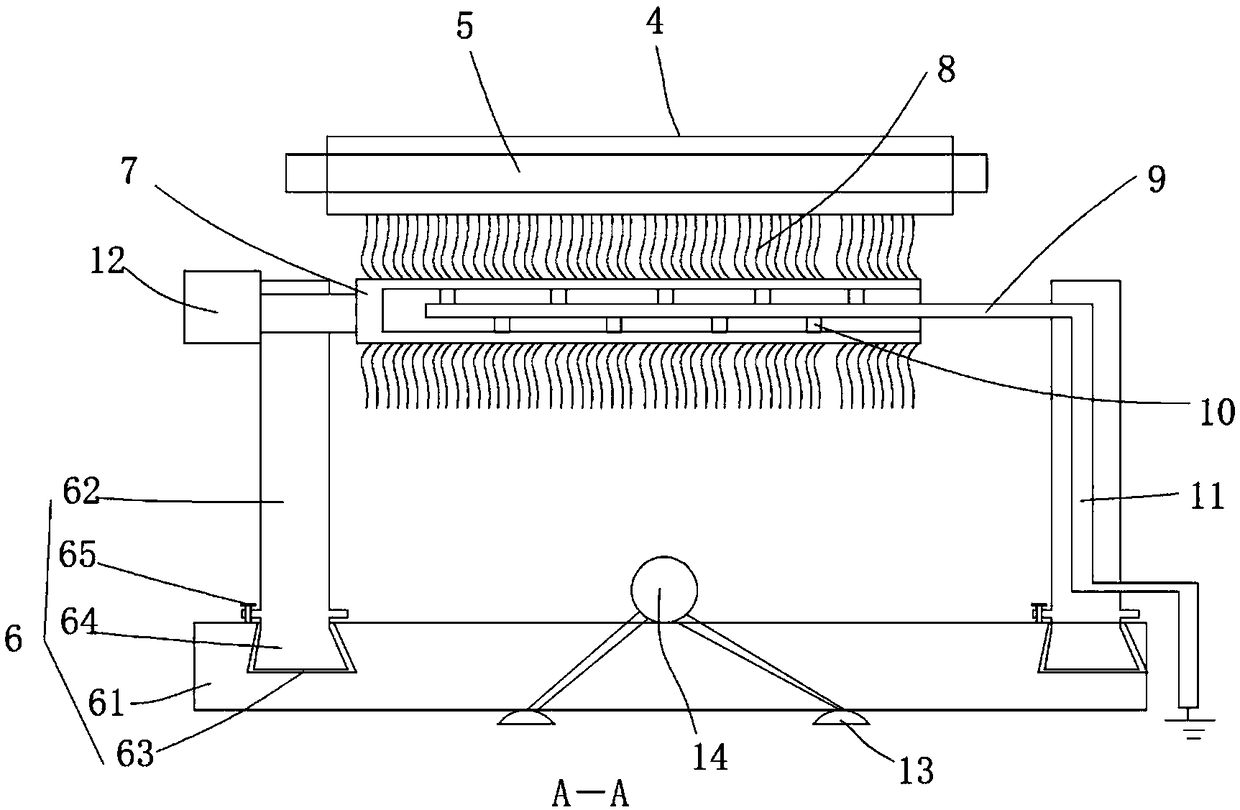

[0014] figure 1 with figure 2 A specific embodiment of the invention is shown in which figure 1 It is a schematic diagram of the overall structure of the present invention; figure 2 for figure 1 Middle A-A cut-away diagram. See figure 1 with figure 2 , a static elimination brush structure for vacuum aluminum plating, including a vacuum evaporation chamber 1, an unwinding device 2 and a winding device 3, the above-mentioned structure is a conventional structure of the prior art, in the unwinding device 2 and the winding device 3 A shaft roller 5 with a plastic protective layer 4 wrapped on the surface is arranged on it, and a static removal bracket 6 is also provided. A round shaft 7 is arranged on the static removal bracket 6, and the round shaft 7 is in one-to-one correspondence with the shaft rollers. Located directly below the shaft roller, an antistatic brush 8 is provided on the surface of the circular shaft 7, and a static elimination guide rod 9 is arranged ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com