Combined type smoke discharging flue device for preventing smoke from flowing backwards

A combined, flue gas technology, applied in the field of photovoltaic solar energy, can solve the problems of pipeline negative pressure or static pressure reduction, uneven product quality, unfavorable transportation and installation, etc., to achieve stable product quality, exquisite structure, and use methods reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

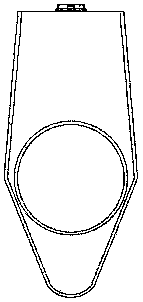

Image

Examples

Embodiment Construction

[0009] The present invention will be further explained below in conjunction with the accompanying drawings.

[0010] A combined smoke exhaust airway device for preventing smoke backflow, characterized in that: it includes a smoke exhaust airway body, wherein the side of the air inlet is provided with an air inlet for connecting the exhaust airway; the upper port of the flue gas channel The opening is used as the air outlet; the auxiliary channel hole is connected to the main channel hole through the flow-increasing hole; the air inlet hole is arranged on the side wall of the exhaust gas channel.

[0011] The above content is only a preferred embodiment of the present invention, and is not intended to limit the implementation of the present invention. Appropriate modifications or modifications made by those skilled in the art according to the concept of the present invention should be within the scope of protection of the present invention. Inside.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com