A turbine inner cylinder structure

A turbine and inner cylinder technology, which is applied in the direction of machine/engine, mechanical equipment, engine components, etc., can solve the problems of the cylinder structure is not compact enough, the sealing performance and bearing strength are reduced, and it is difficult to meet the technical requirements. Technical difficulty of assembly, improved sealing and pressure-bearing performance, and the effect of strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

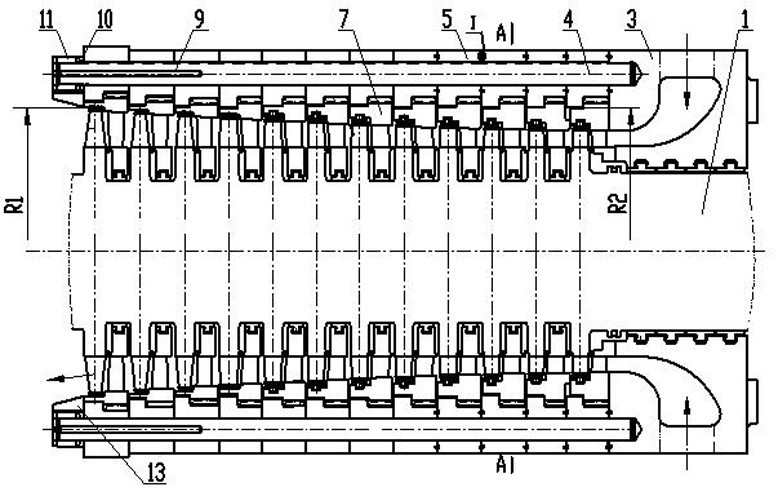

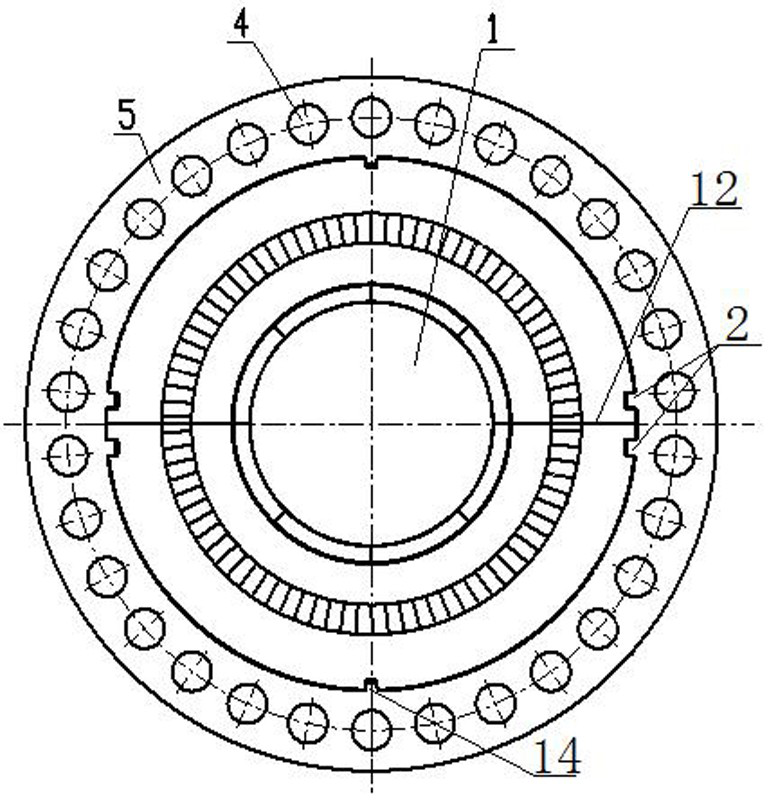

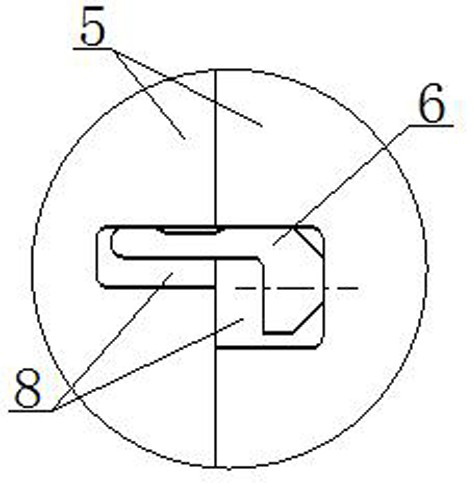

[0026] see figure 1 , figure 2 and image 3 As shown, the present invention includes an inner cylinder body, which has a plurality of cylindrical cylinder sections 5 and several tie rod bolts 4 .

[0027] Among them, the cylinder body section 5 of the inner cylinder body is divided into sections according to the relative positions of the stationary vane assemblies 7 of each level and the steam inlet chamber 3, that is, the inner cylinder body is divided into multiple cylinder sections according to the stationary vane assemblies 7 of each level. 5. At the same time, separate the cylinder section corresponding to the first-stage stationary vane assembly from the steam inlet chamber 3 (in particular, in a broad sense, the steam inlet chamber 3 is also a cylinder section, here for clarity, the steam inlet chamber Chamber 3 is listed separately), and each cylinder section 5 is correspondingly installed with a first-stage vane assembly 7 . There are several bolt holes arranged o...

Embodiment 2

[0035] The invention includes an inner cylinder body having a plurality of cylindrical cylinder body sections and a plurality of tie rod bolts.

[0036] Among them, the cylinder body section of the inner cylinder body is divided into segments according to the relative positions of the stationary vane assemblies of each level, that is, the inner cylinder body is divided into multiple cylinder block sections according to the stationary vane assemblies of each level. The corresponding cylinder section is integrated with the steam inlet chamber, and each cylinder section is correspondingly equipped with a first-stage vane assembly. A number of bolt holes are arranged on the wall thickness circumference of each of the aforementioned cylinder sections, among which the bolt holes on the cylinder section corresponding to the first-stage stationary vane assembly are of threaded structure, and the bolt holes on the other cylinder sections are through holes. Hole structure, the bolt hole...

Embodiment 3

[0044] The invention includes an inner cylinder body having a plurality of cylindrical cylinder body sections and a plurality of tie rod bolts.

[0045] Wherein, the cylinder body section of the inner cylinder body is divided into segments according to the relative positions of the first-stage stator vane assembly, specifically, the cylinder block section corresponding to the first-stage stator vane assembly is integrated with the steam inlet chamber, The second-stage and third-stage vane assemblies correspond to one cylinder section, the fourth-stage and fifth-stage vane assemblies correspond to one cylinder section, and so on, so that the cylinders of other stages outside the first-stage cylinder section The body sections correspond to the two-stage vane assemblies respectively. Of course, the number of stages of the vane assemblies corresponding to the cylinder section of the last stage is randomly determined according to the number of stages of the total stationary vane ass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com