Seat post type underwater working device

A technology of underwater operation and pipe sitting, which is applied in pipeline laying and maintenance, pipes/pipe joints/fittings, mechanical equipment, etc., and can solve problems such as economic losses, marine environmental pollution, oil and gas leakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

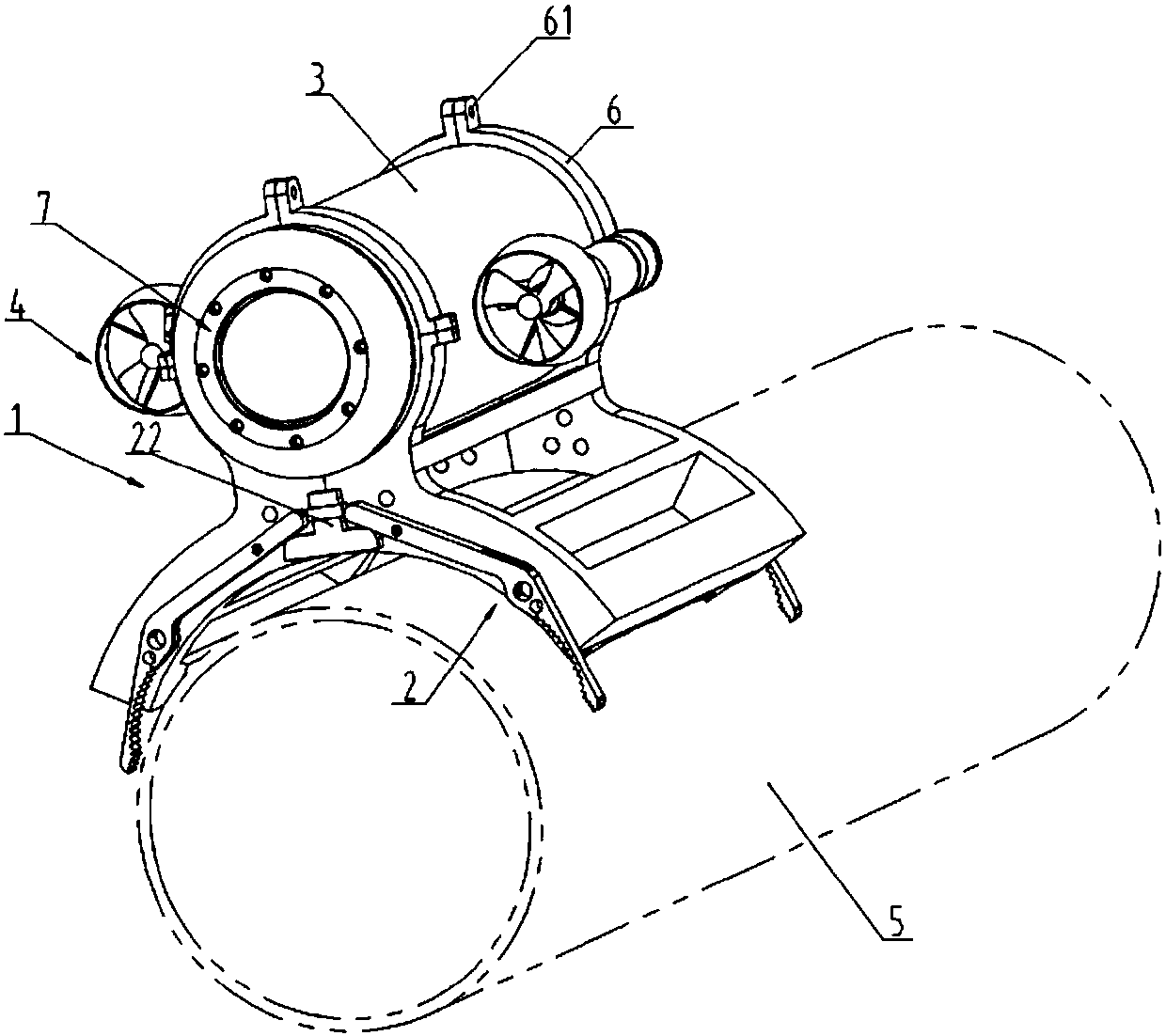

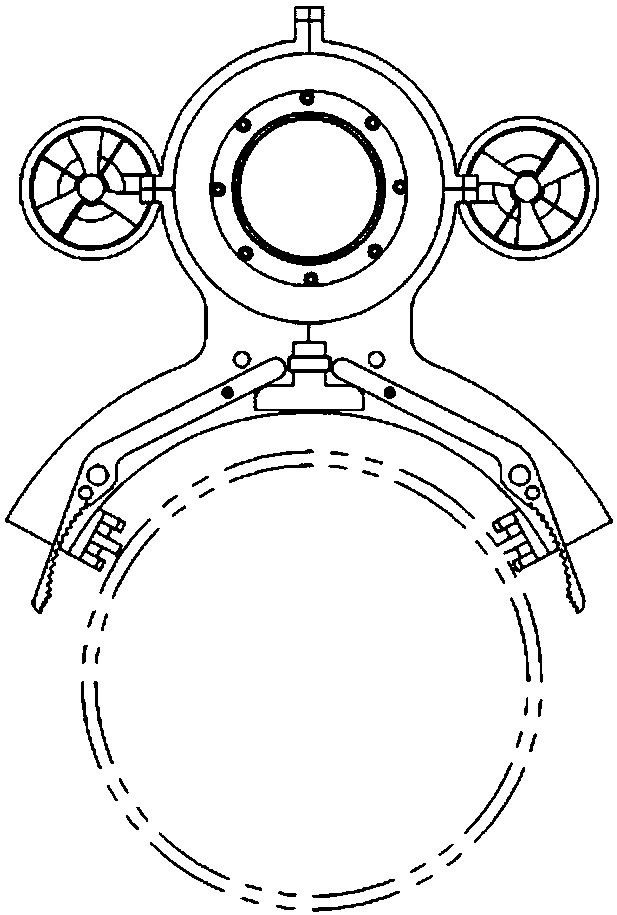

[0018] from figure 1 It can be seen that this embodiment discloses a sitting tube type underwater working device, which mainly includes a sitting tube sliding device 1 , a braking device 2 , a pressure chamber 3 and a propeller 4 . The seat tube sliding device 1 is located on the outer wall of the submarine pipeline 5, the brake device 2 is connected to both ends of the seat tube sliding device 1, the pressure-resistant chamber 3 is fixed on the top of the seat tube sliding device 1, and the propeller 4 is symmetrically fixed on the pressure-resistant The side wall of bin 3.

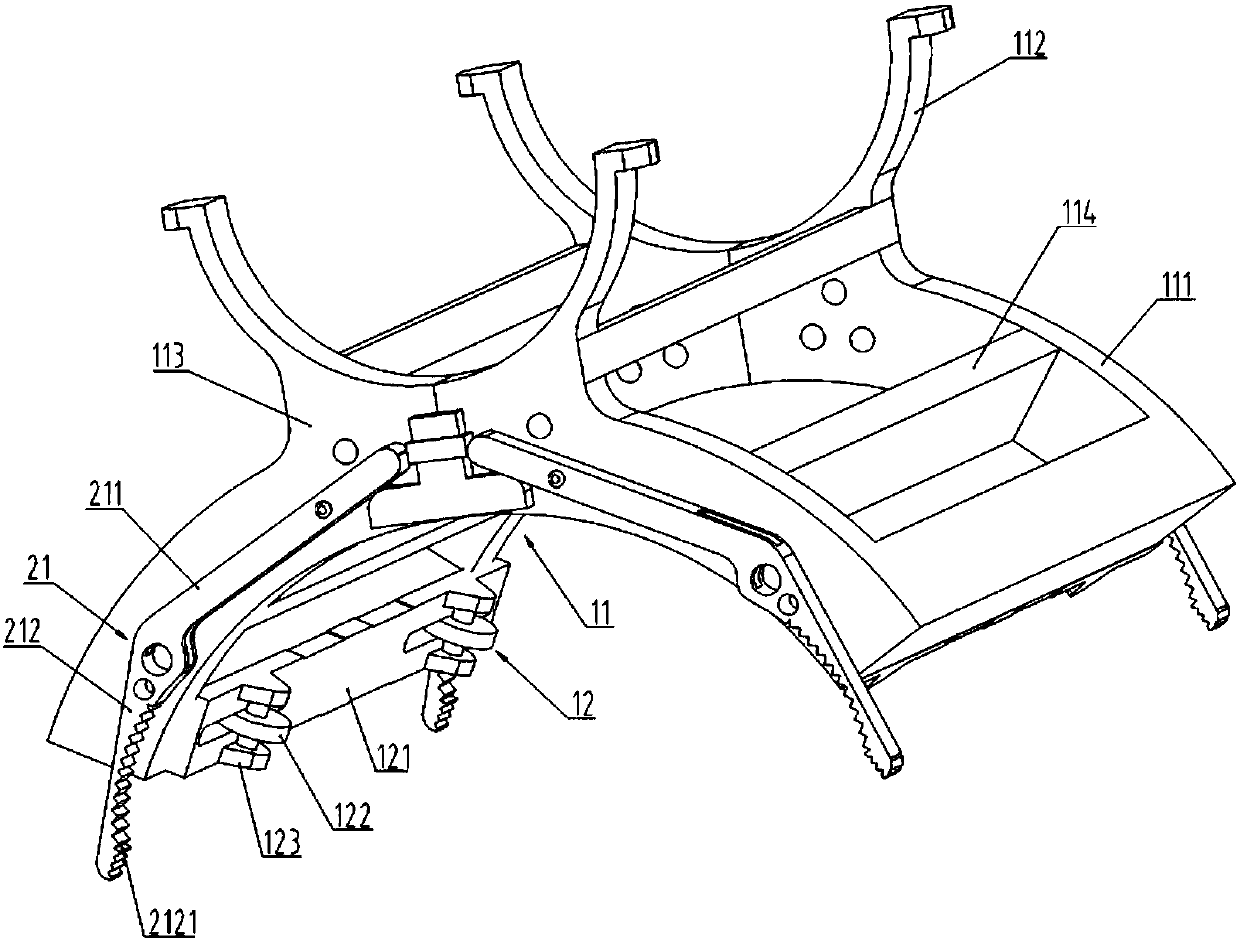

[0019] from figure 2 It can be seen that the seat tube sliding device 1 includes a seat tube bracket 11 and a roller assembly 12 .

[0020] Seat tube bracket 11 comprises end frame and connecting beam. The end frame is an integral part of the lower arc-shaped body 111 with the opening facing downward and the upper arc-shaped body 112 with the opening facing upward. There is a transition seat 113 betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com