Test method for matching degree of smelting performance of blast furnace charges

A test method and matching technology, applied in the field of blast furnace steelmaking, can solve the problem of not being able to simultaneously reflect the matching effect of different iron ore raw material smelting degrees and reflow properties, and achieve the effects of simple operation and accurate measurement results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

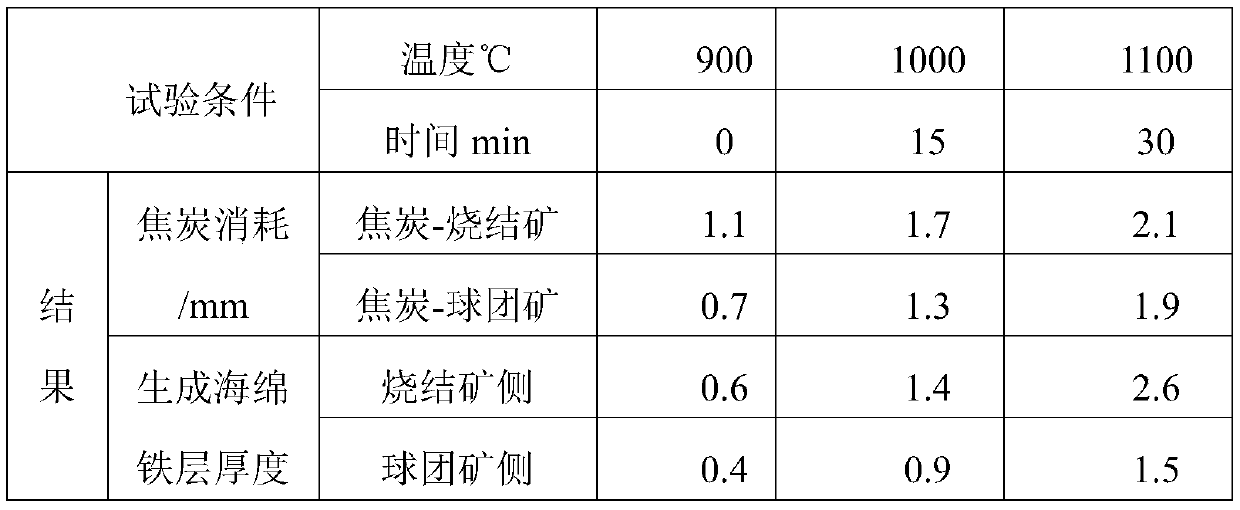

[0022] In order to better explain the present invention, the main content of the present invention is further clarified below in conjunction with specific examples, but the content of the present invention is not limited to the following examples.

[0023] The invention discloses a test method for matching degree of smelting performance of blast furnace charge, which comprises the following steps:

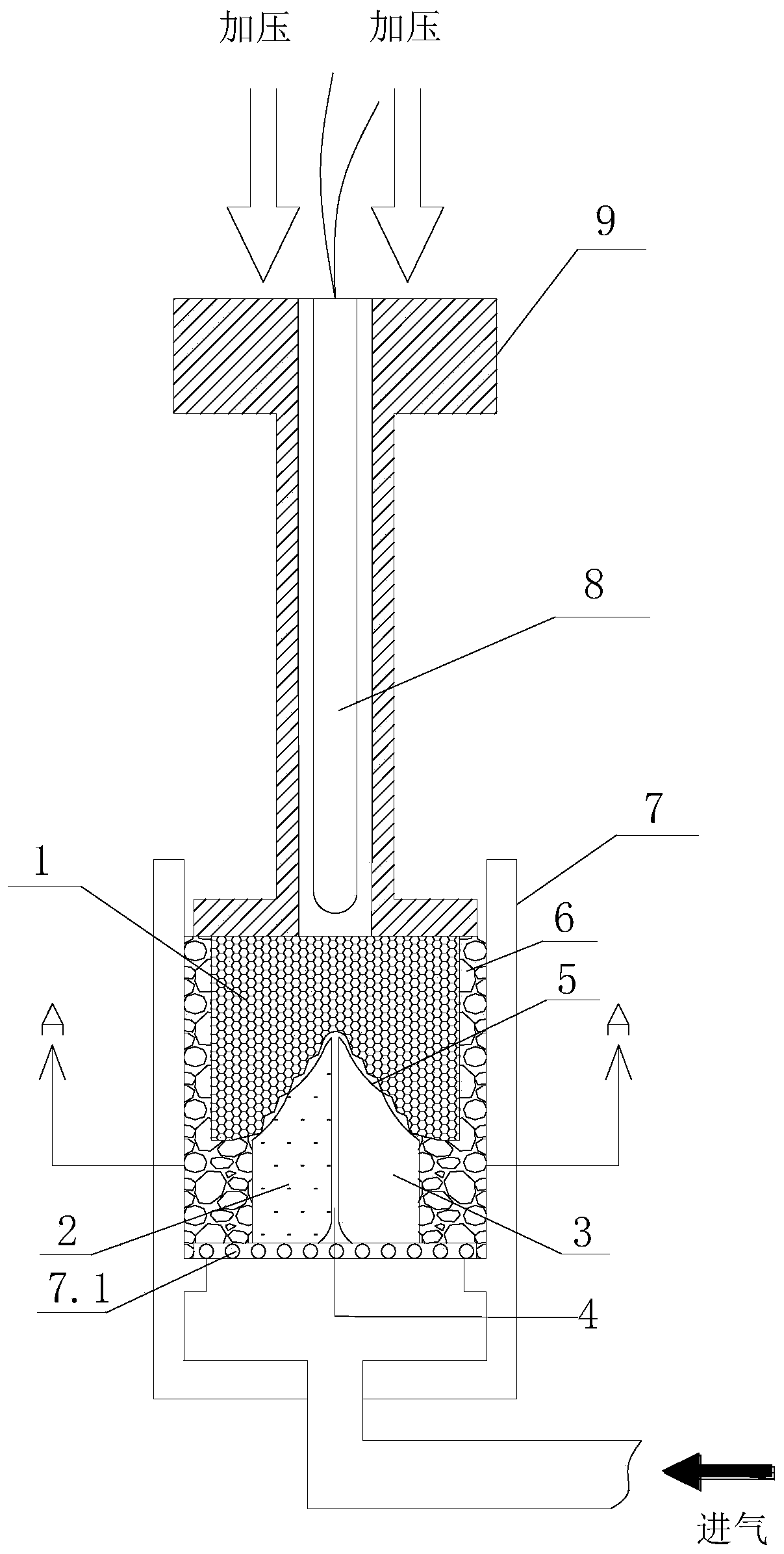

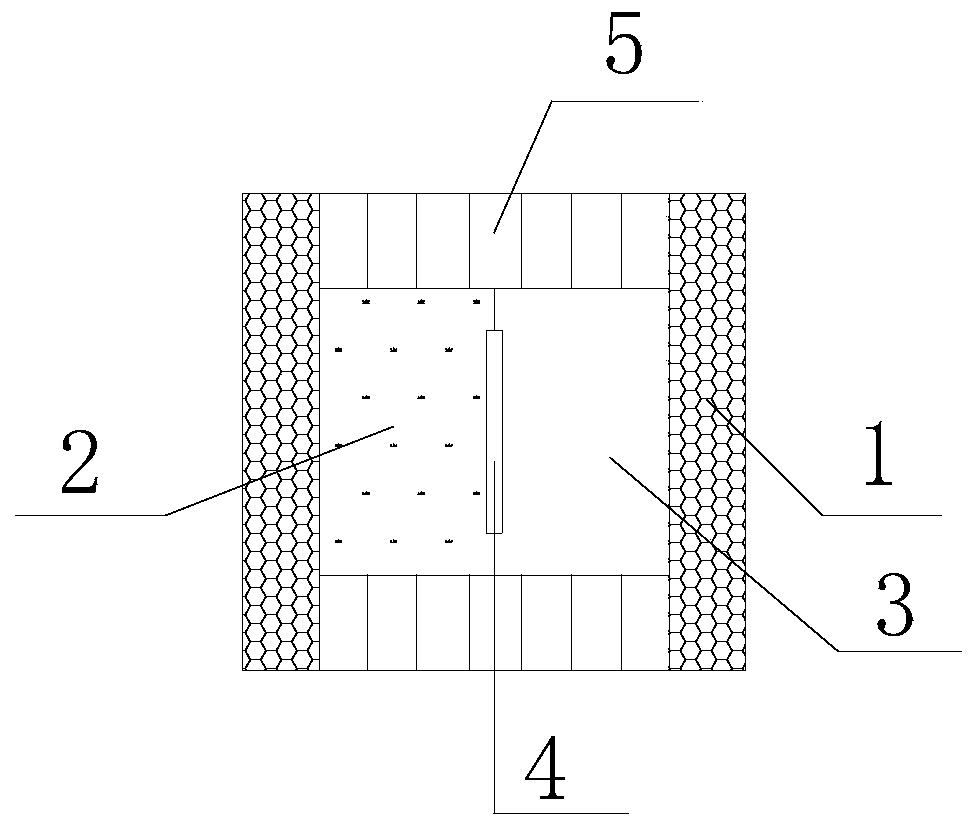

[0024] 1) Prepare the sample to be tested: the sample to be tested is a combined sample of a coke sample 1 with a height of 40-60 mm and an iron ore sample with a height of 13-17 mm, and the coke sample 1 is a solid cube structure, such as figure 1 As shown, the cube structure is preferably a cube structure, and the height of the cube structure is preferably 50mm. A groove is provided along one side of the cube. When the surfaces are in contact with each other, a coke-mineral air gap 5 is formed between the surfaces; in the embodiment of the present invention, the preferred groove...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com