Test module for compression type IGBT device power cycle test

A technology for testing modules and power cycles, which is applied in the direction of single semiconductor device testing, instruments, and electrical measurement. It can solve the problems of low cooling efficiency and achieve the effects of ensuring stability, preventing insufficient cooling capacity, and ensuring connection stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

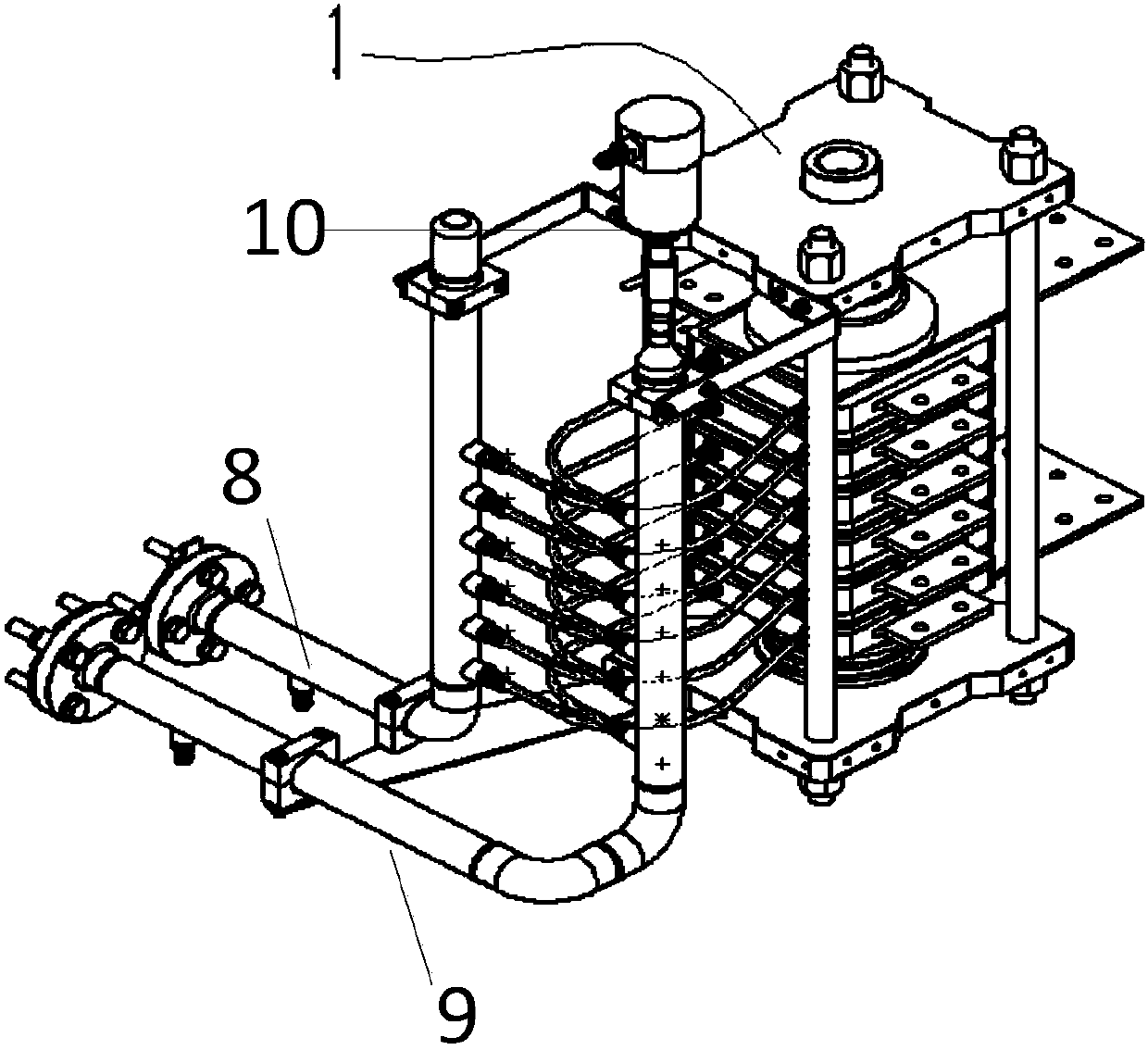

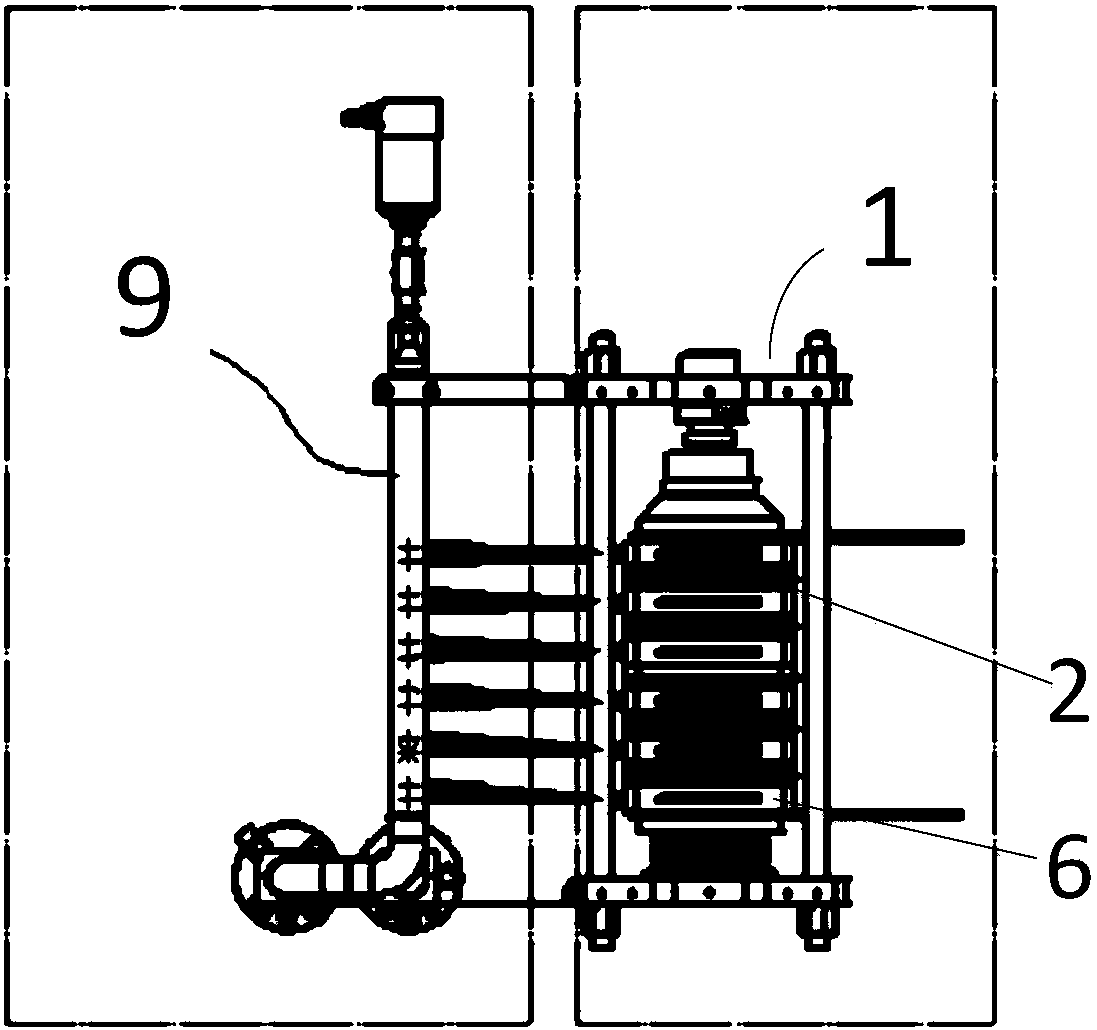

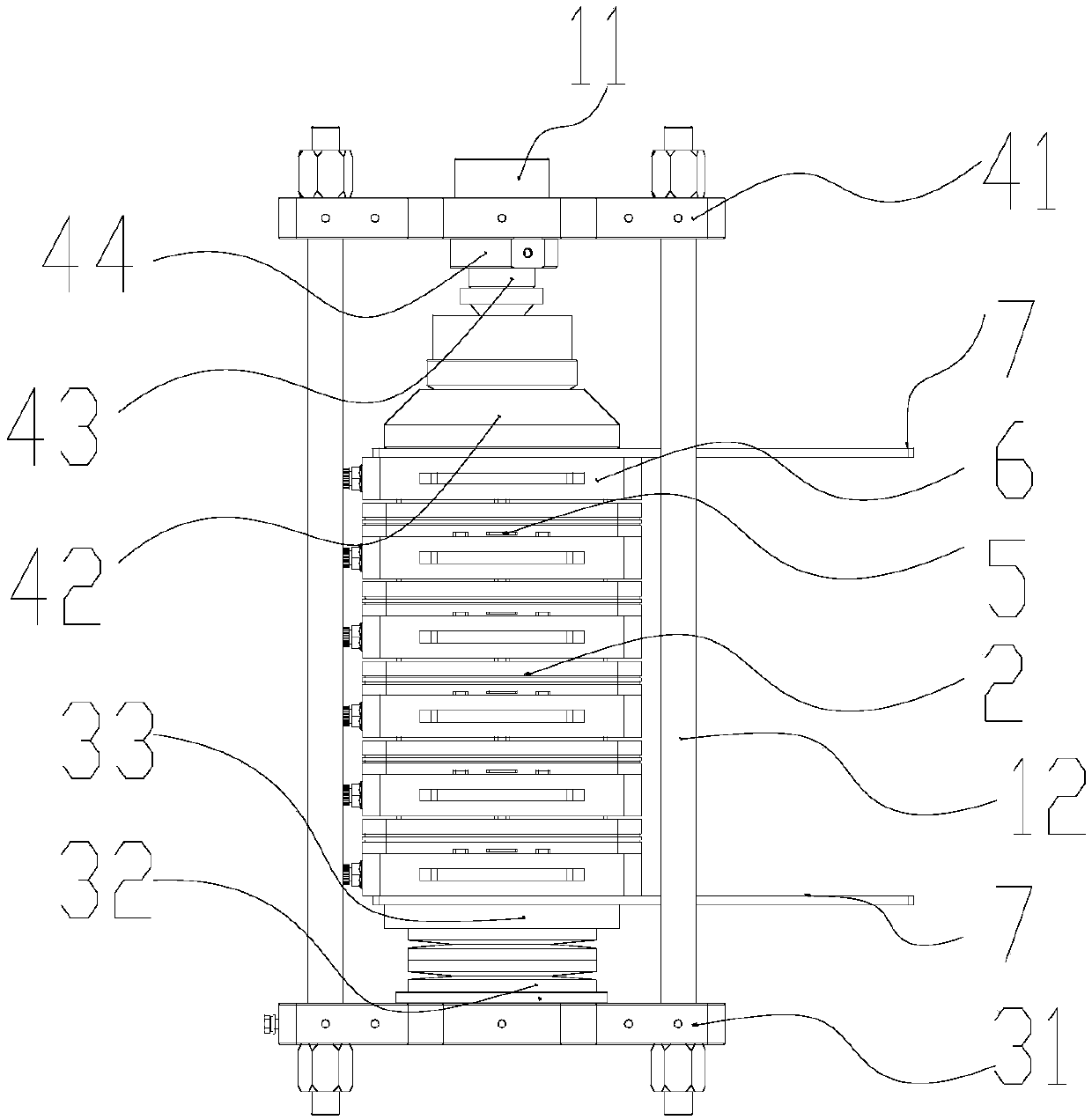

[0039] The present embodiment provides a test module for the power cycle test of the crimping type IGBT device, comprising: a test assembly 1, the test assembly 1 includes a plurality of sets of devices to be tested 2 arranged in parallel with each other; the circulating water system is provided with multiple A set of cooling water assemblies respectively connected to each of the devices under test 2 , and each group of the cooling water channels respectively cools the devices under test 2 connected thereto.

[0040] In the prior art, the water circuit used for cooling of the test platform is arranged in series, and the cooling water flows through multiple IGBT devices to be tested one after another. When the cooling water flows through the IGBT devices located at the rear, the water temperature is already very high. The cooling capacity plummeted.

[0041] In the test module provided in this embodiment, multiple devices under test 2 are arranged in parallel, and each device u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com