Reliable easy-to-maintain economic junction box

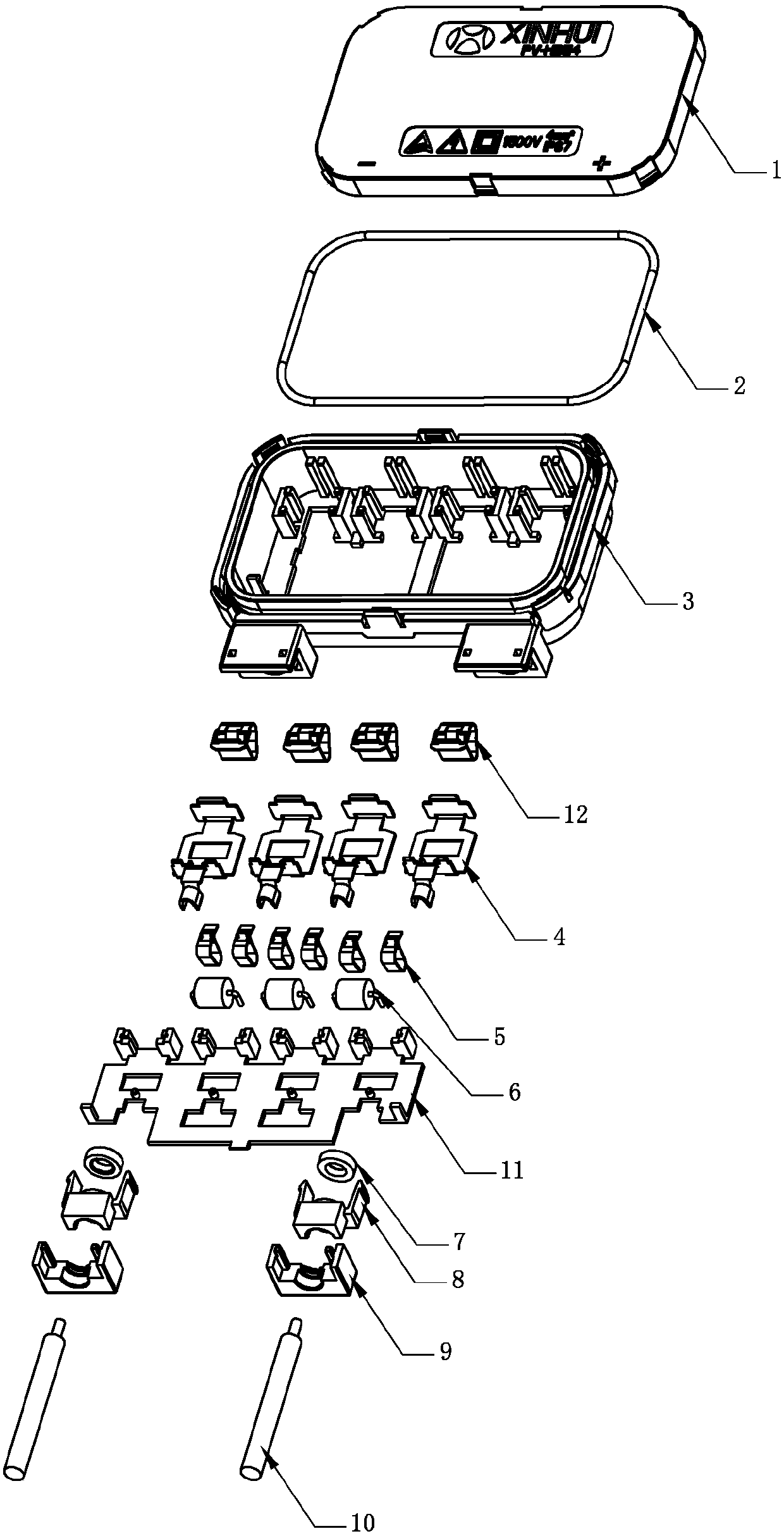

An easy-to-maintain, junction box technology, applied in the direction of connection, connecting device parts, electrical components, etc., can solve problems such as difficulty in ensuring the installation of diodes in place, easy-to-damage clips when removing diodes, and lack of particularly good design solutions. The effect of strong line reliability, easy replacement and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

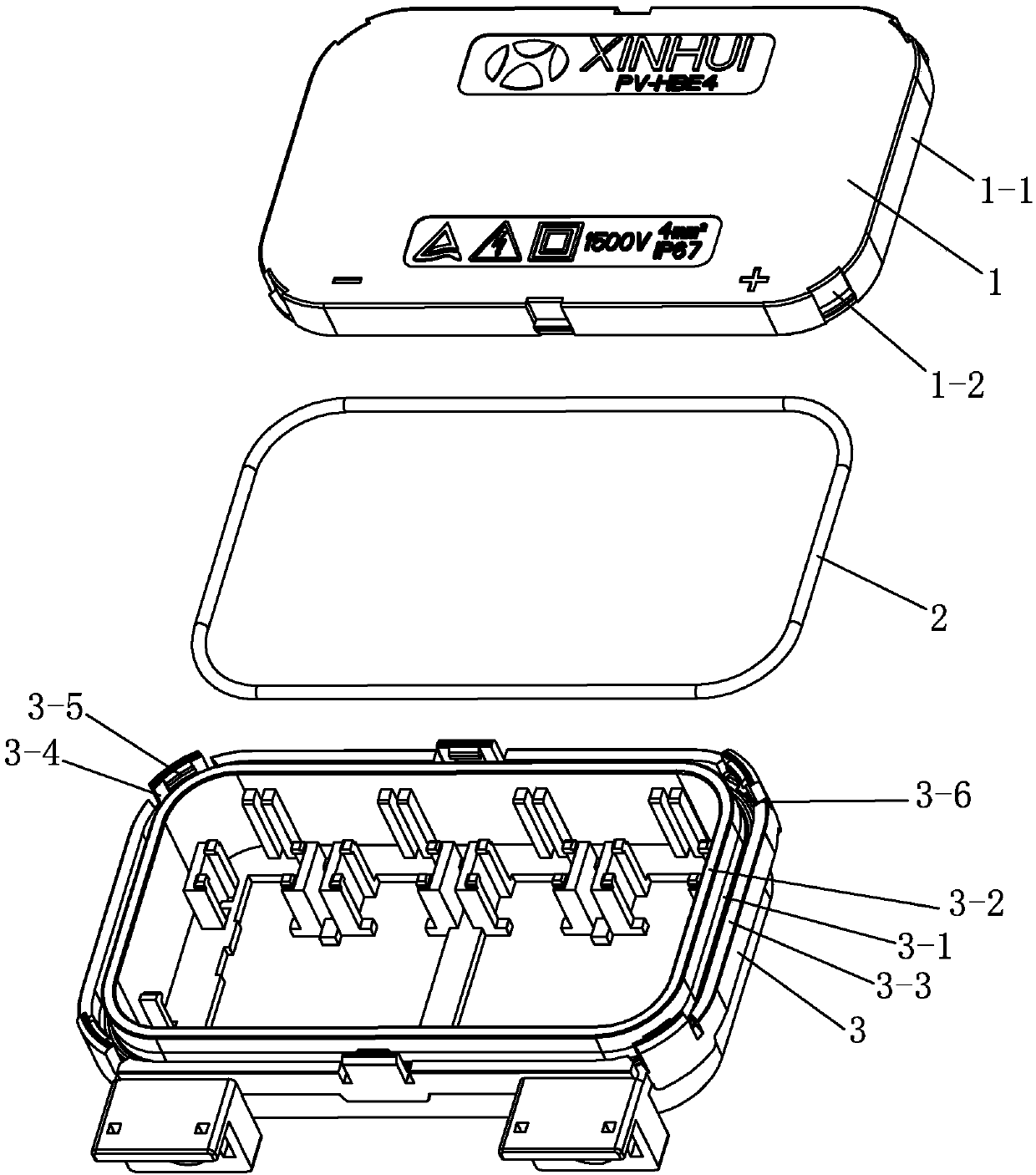

Method used

Image

Examples

Embodiment 1

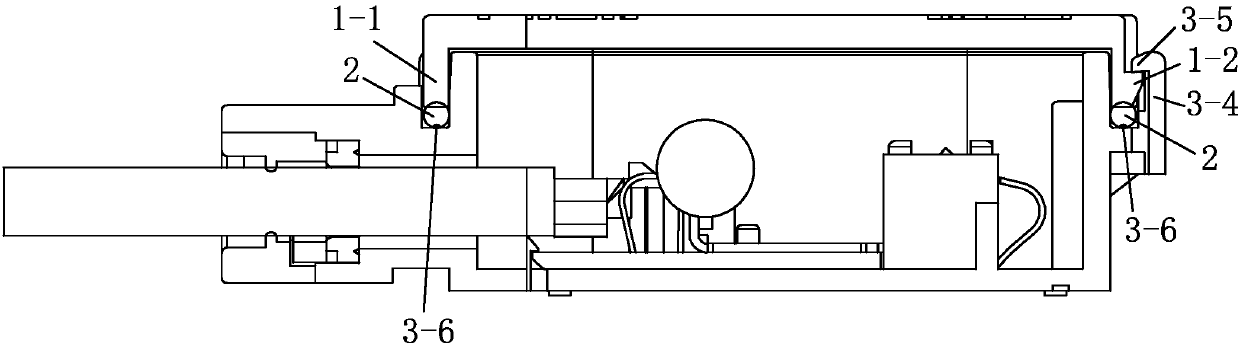

[0044] Such as Figure 6 As shown, the base 3 is a base for installing the cable sealing ring 7 , the sealing pressing block 8 and the wire pressing block 9 . The cable entrance of the base 3 is provided with a sealing pressing block mounting seat 3-7 and a wire pressing block mounting seat 3-8, and the two are connected as one. A wire insertion hole 3-9 is provided in the middle of the sealing briquetting mounting seat 3-7, and the inwall of the wire insertion hole 3-9 is provided with a ring sealing ring placement groove 3-10, and the both sides of the wire insertion hole 3-9 are provided with two A block 3-11, in this embodiment, the specific structure of the block 3-11 is a fixed sealing block hook formed by the outer side of the back of the groove after the sealing block mounting seat 3-7 is grooved. buckle (see Figure 14 ). Two slots 3-12 are arranged on both sides of the wire crimping block mounting base 3-8.

[0045] Such as Figure 7 As shown, the sealing pressi...

Embodiment 2

[0051] refer to Figure 18 , combined with Figure 19 ~ Figure 23 , the base 3 is provided with a wire insertion hole 3-9, and the sealing pressure block 8 is also provided with a wire insertion hole 8-3 of the same size. Close to the rear of the wire insertion hole 8-3 of the sealing pressing block 8, such as Figure 19 shown. Then put the sealing briquetting block 8 with the cable sealing ring 7 installed into the base 3. At this time, the other end surface of the cable sealing ring 7 is close to the wire insertion hole 3-9 of the base 3, and the cable is sealed. Ring 7 communicates with the wire insertion hole 8-3 on the sealing pressing block 8 and the wire insertion hole 3-9 on the base 3, as Figure 20 shown. Insert the cable 10 so that it passes through the wire insertion hole 8-3 on the sealing pressing block 8, the cable sealing ring 7, and the wire insertion hole 3-9 on the base 3 in sequence, and then connects with the components in the base 3, such as Figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com