Cereal winnowing machine separator

A separator and winnowing machine technology, applied in the direction of solid separation, separation of solids from solids with airflow, agricultural machinery and implements, etc., can solve the problems of low separation efficiency, single function, poor separation effect, etc., to achieve High separation efficiency, high safety, and the effect of improving efficiency and effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

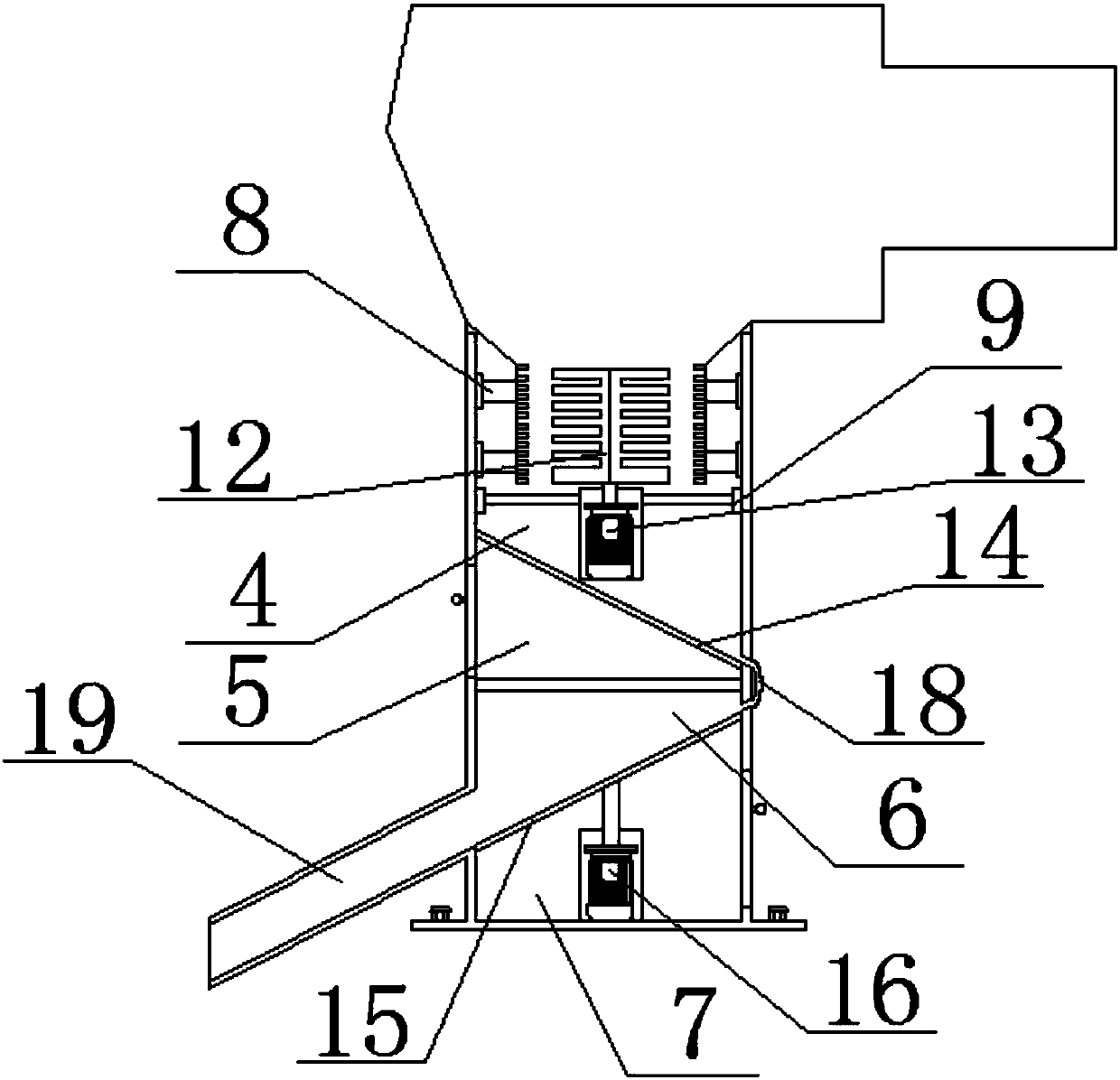

[0020] As a preferred embodiment of the present invention, the foreign matter chamber door 17 is provided with a handle.

[0021] As a preferred embodiment of the present invention, the number of the mixing drum mounting bases 8 is four, and the number of the motor mounting bases 9 is two.

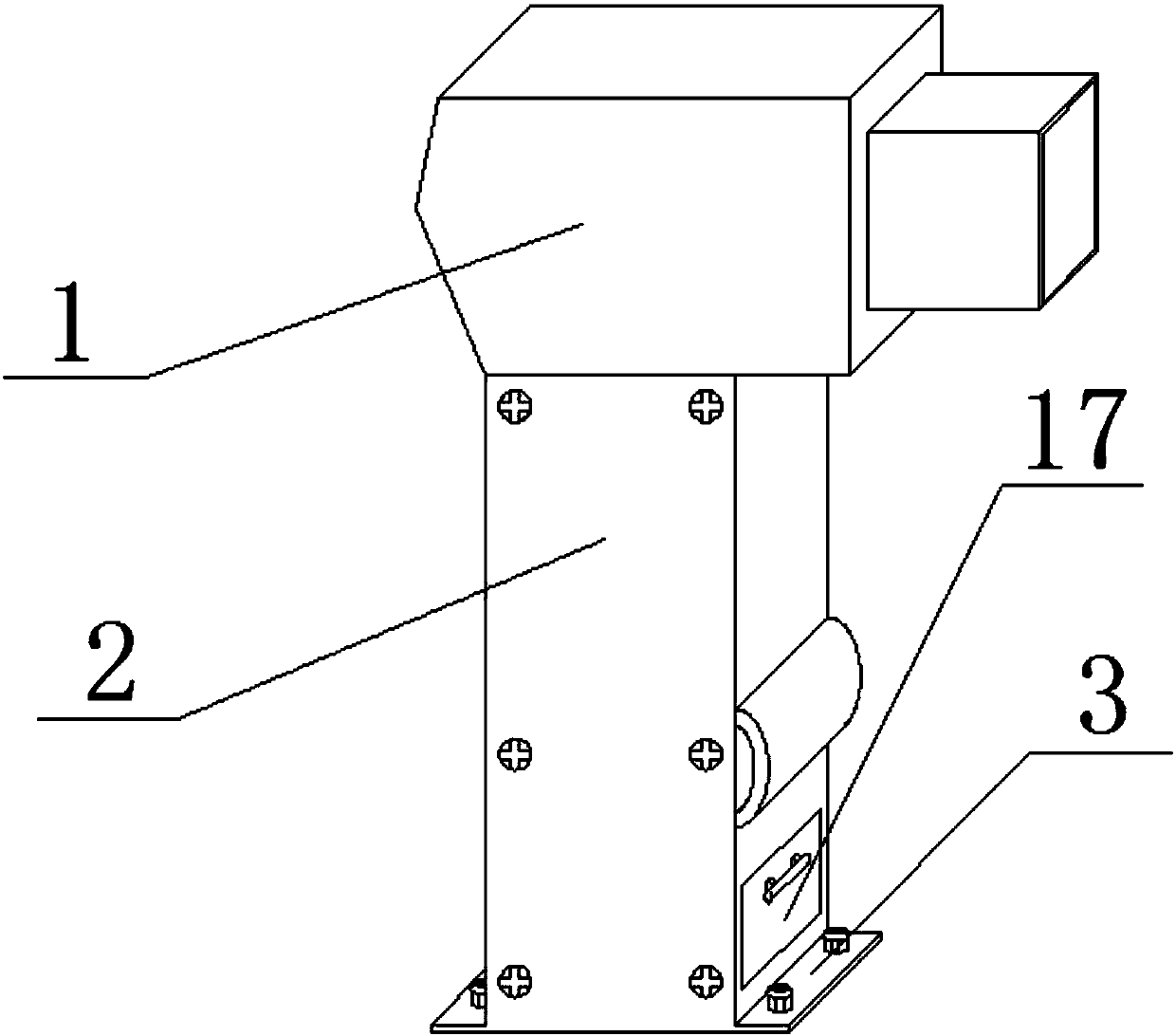

[0022] As a preferred embodiment of the present invention, the bottom of the separation chamber 2 is provided with a base 3 .

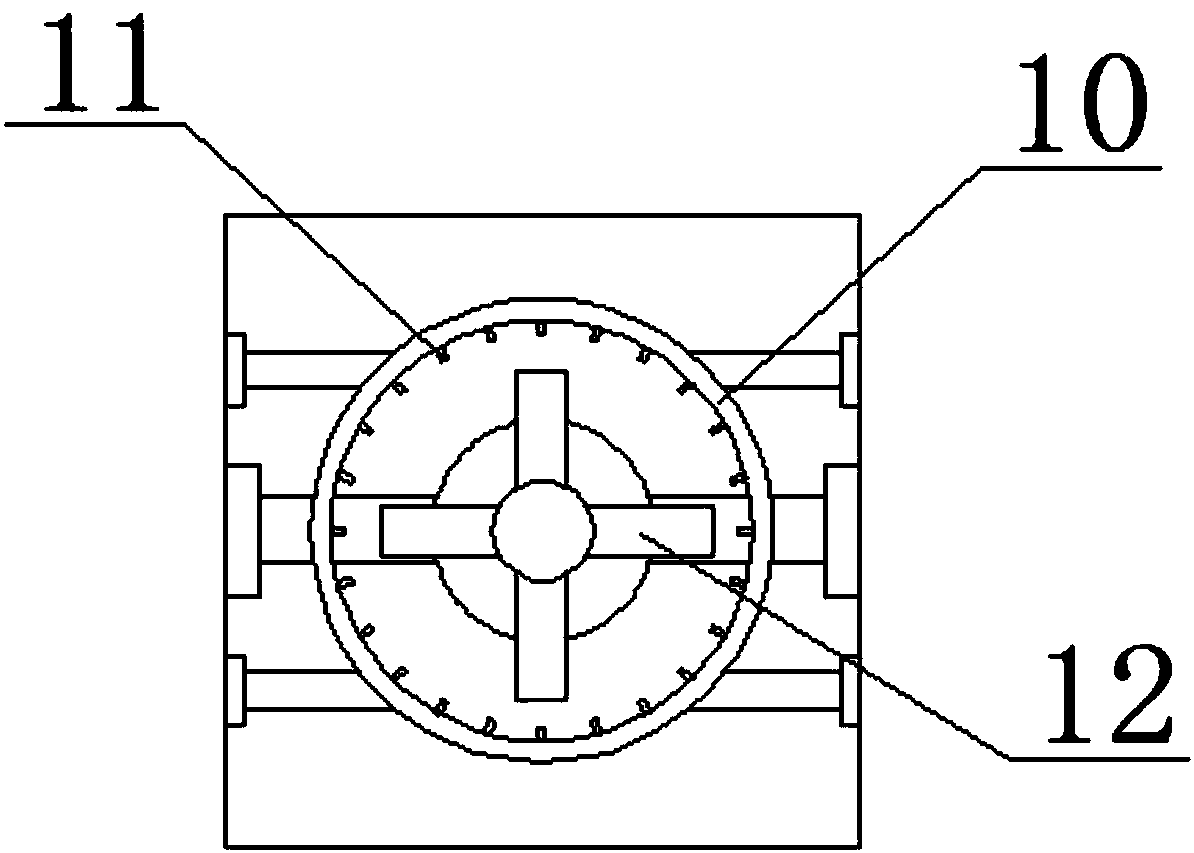

[0023] Working principle: When using the separator of the grain winnowing machine, install the separator on the grain winnowing machine, after turning on the grain winnowing machine, the winnowing machine starts to thresh the grain, and at the same time, the external power supply is the motor 13 and the vibrating motor 16 provides electric energy, the motor 13 drives the stirring head 12 to rotate in the mixing drum 10, the vibrating motor 16 drives the filter screen 2 15 to vibrate, and the grain enters the grain inlet box 1 and then enters the filter chamber 1 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com