Assembly for adjusting and controlling operation resistance of pulse-type dust collector

An operating resistance, pulsed technology, used in the separation of dispersed particles, chemical instruments and methods, and filtration of dispersed particles, etc., can solve the problems of filter bag damage, high maintenance cost of filter bag pulse dust collectors, etc., and improve the service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

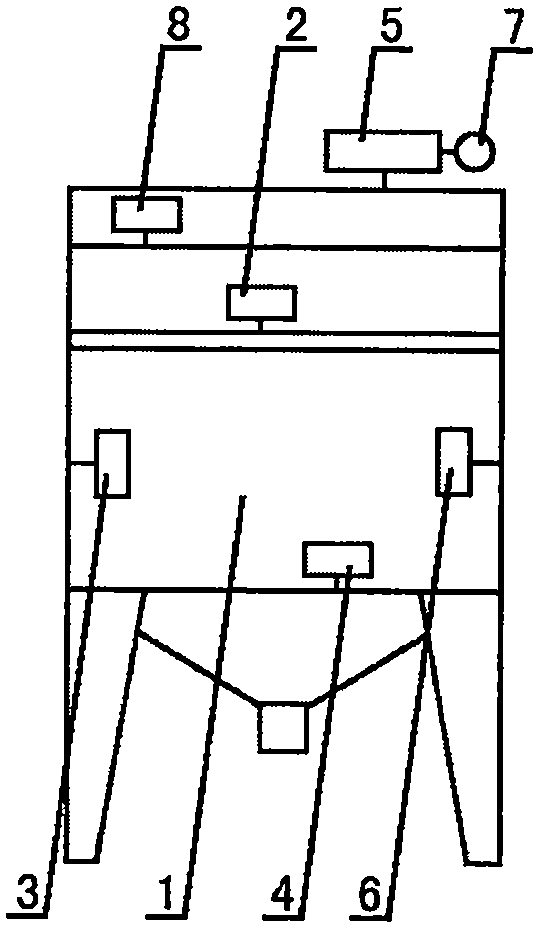

[0012] Embodiment: as shown in the accompanying drawing. The running resistance control component of the pulse dust collector includes a body (1), on which a pressure sensing module (2), a detection module (3), a transmission module (4), a management module (5), pressure The sensing module (2) senses the pressure at the compressed air source, the detection module (3) detects whether the filter bag has condensation or damage, and the detected information is transmitted to the management module (5) through the transmission module (4) ), finally there is a management module (5) for processing.

[0013] The running resistance control component of the pulse dust collector is equipped with a dust removal device (6) on the body (1), which can remove debris in the pulse valve in time to prevent malfunction.

[0014] The running resistance control component of the pulse dust collector is equipped with a prompt module (2), which sends a prompt message when the filter bag of the body (1...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap