Vehicle load induction system for introducing loads against the direction of travel of the vehicle

A travel direction, introduction system technology, applied in vehicle components, vehicle safety arrangements, bumpers, etc., can solve problems such as weight increase, deformation of central load support, cost increase, etc., to achieve the effect of simple force transmission connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

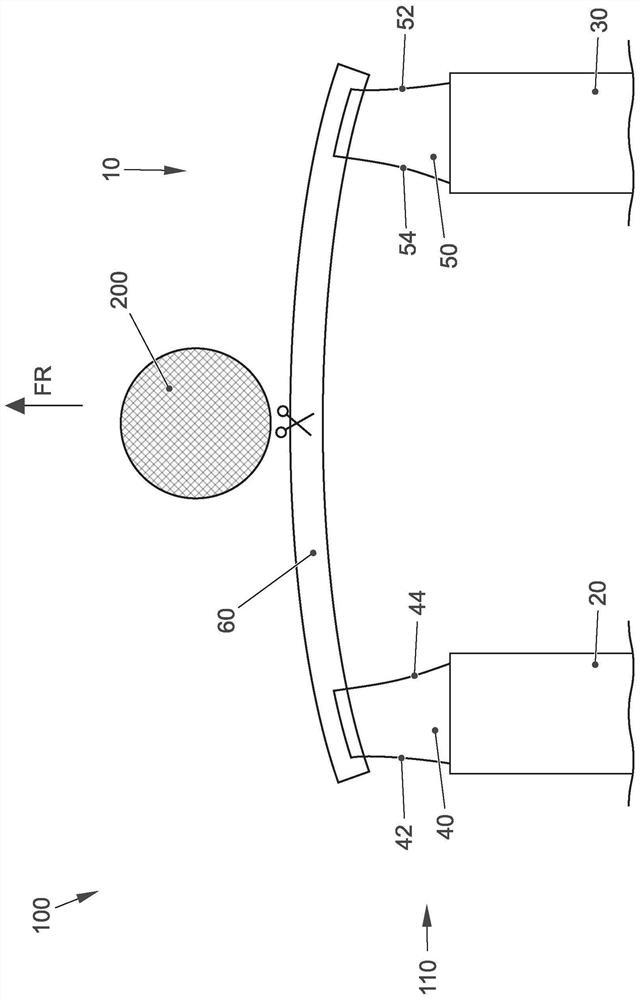

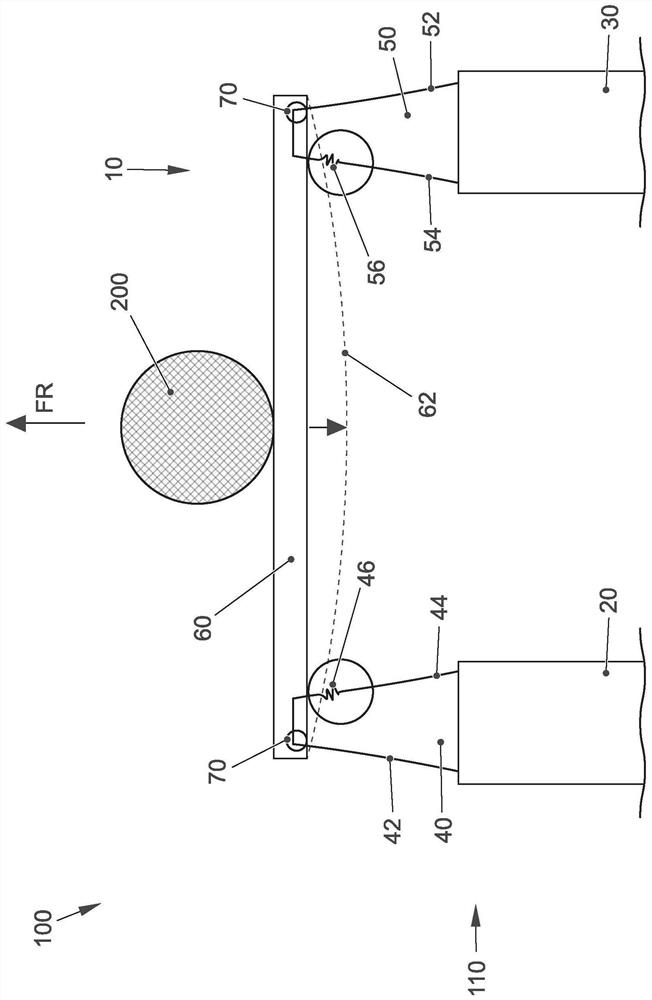

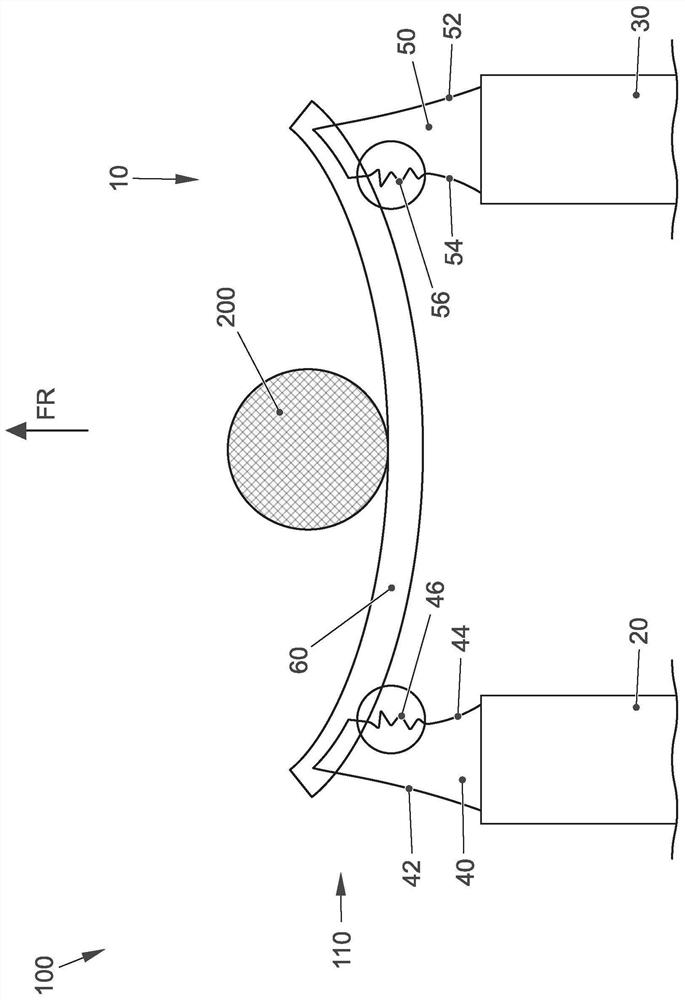

[0038] Figure 1 to Figure 5 A load induction system 10 according to the invention is shown. Here, this load introduction system 10 is shown in a collision situation with a central object 200 (the central object may also be understood to mean the center pillar). The various stages of this deformation show how the deformation is carried out under loads of different intensities. Depending on the impact velocity and the corresponding magnitude of the load to be introduced, this deformation will be carried out only through some of the deformation steps explained below, or will carry out all deformations with higher load inputs, respectively. In all deformation cases, i.e., in accordance with Figure 1 to Figure 2 or Figure 1 to Figure 3 In the case of slight deformations, but also in the Figure 1 to Figure 5 The advantage according to the invention of the inward buckling of the load introduction system 10 can be easily seen in all cases in the case of severe deformation of ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com