Hot air fuel gas oven device

A technology of gas and oven, which is applied in the direction of lining repair, etc. It can solve the problems of inability to adjust, fix the hot air efficiency, increase the cost of oven equipment, etc., and achieve the effects of reducing production costs, improving hot air control accuracy, and reducing labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

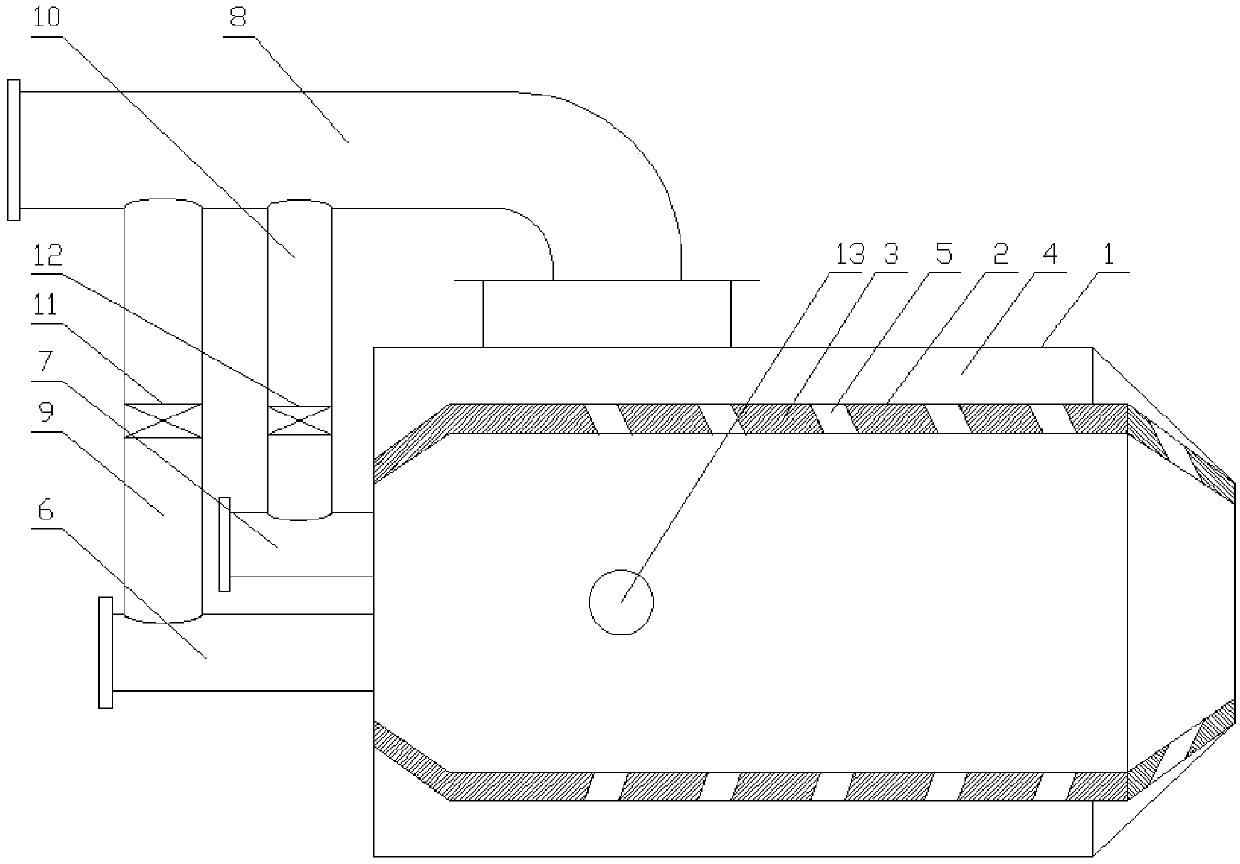

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0019] Such as figure 1 As shown in the structural diagram of the present invention, the present invention provides a hot air gas oven equipment, comprising a furnace body 1, an inner container 2 is set inside the furnace body 1, and a refractory layer 3 is arranged inside the inner container 2, so that A combustion-supporting channel 4 is formed between the furnace body 1 and the inner container 2, and ventilation holes 5 are correspondingly provided on the surrounding walls of the inner container 2 and the refractory layer 3, and a vent hole 5 is provided on one side of the furnace body 1 to be connected with the inner container 2. The connected main gas pipeline 6 and auxiliary gas pipeline 7 are communicated with an air pipeline 8 on the side wall of the furnace body 1, and the main gas pipeline 6 and the auxiliary gas pipeline 7 pass through the main combustion-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com