PCB v-cut misoperation correction process and pcb processing process

A V-CUT, PCB board technology, used in printed circuits, electrical components, printed circuit manufacturing, etc., can solve problems such as positioning, waste material processing efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

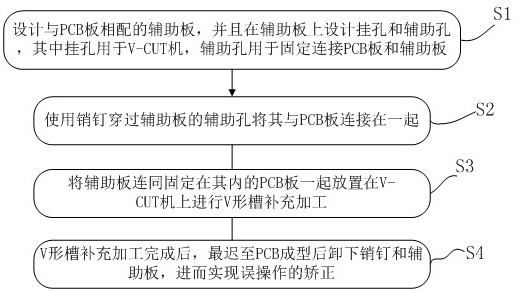

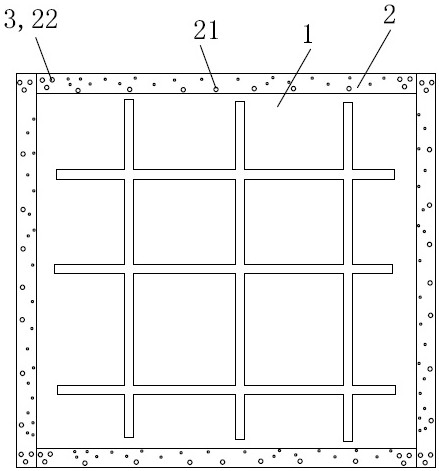

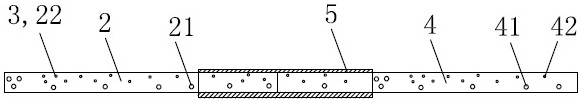

[0026] Such as figure 1 As shown, the PCB board V-CUT misoperation correction process method at least includes the following steps: S1. Design an auxiliary board 2 matching the PCB board 1, and design a hanging hole 21 and an auxiliary hole 22 on the auxiliary board, wherein the hanging hole is used for For the V-CUT machine, the auxiliary hole is used to fix the connection between the PCB board and the auxiliary board;

[0027] S2. Use pin 3 to pass through the auxiliary hole of the auxiliary board to connect it with the PCB board;

[0028] S3. Place the auxiliary board together with the PCB board fixed in it on the V-CUT machine for V-shaped groove supplementary processing;

[0029] S4. After the supplementary processing of the V-shaped groove is completed, the pin and the auxiliary board are removed at the latest after the PCB is formed, and then the correction of the misoperation is realized.

[0030] In the above-mentioned embodiment, the diameter of the hanging holes...

Embodiment 2

[0037] PCB board processing technology, at least including text technology, tin spraying technology, molding technology and V-CUT technology in sequence, of which:

[0038] V-CUT process, the detachable process auxiliary board is connected outside the four edges of the PCB board. The process auxiliary board is provided with hanging holes and auxiliary holes. The hanging holes are used for V-CUT machine, and the auxiliary holes are used for fixed connection to the PCB board. And the auxiliary board; remove the detachable process auxiliary board after the V-groove processing is completed.

[0039] In this embodiment, similar to Embodiment 1, each detachable process auxiliary plate is provided with a process connection hole at the end position, and two adjacent detachable process auxiliary plates are connected by a pin connection, through these process connection holes to rotatably connect them together. The detachable process auxiliary boards are detachably connected by pin sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com