Air duct variable radiator

A variable, radiator technology, used in cooling/ventilation/heating transformation, electrical components, electrical equipment structural parts, etc. The effect of eliminating local eddy currents, improving heat dissipation efficiency and reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

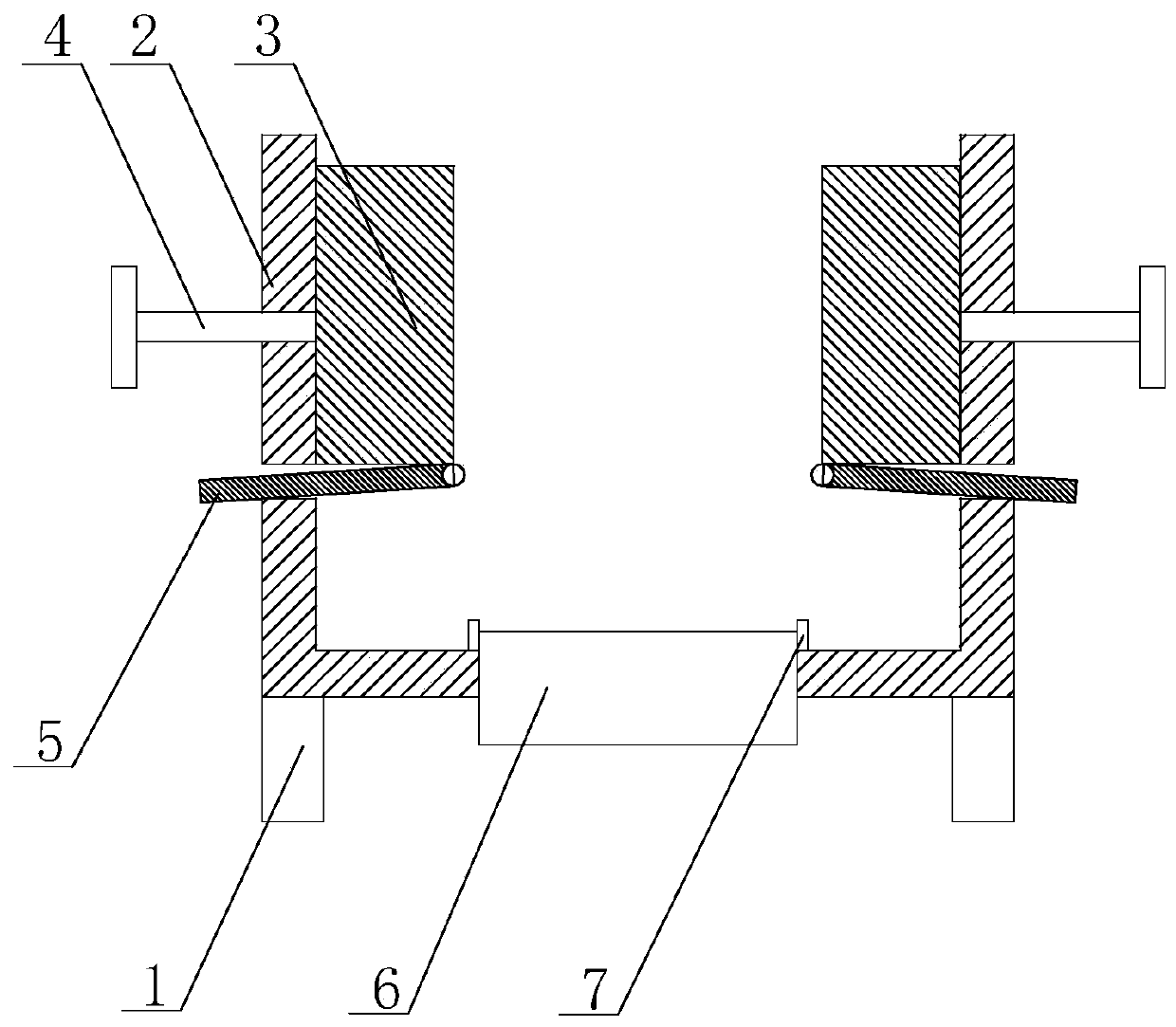

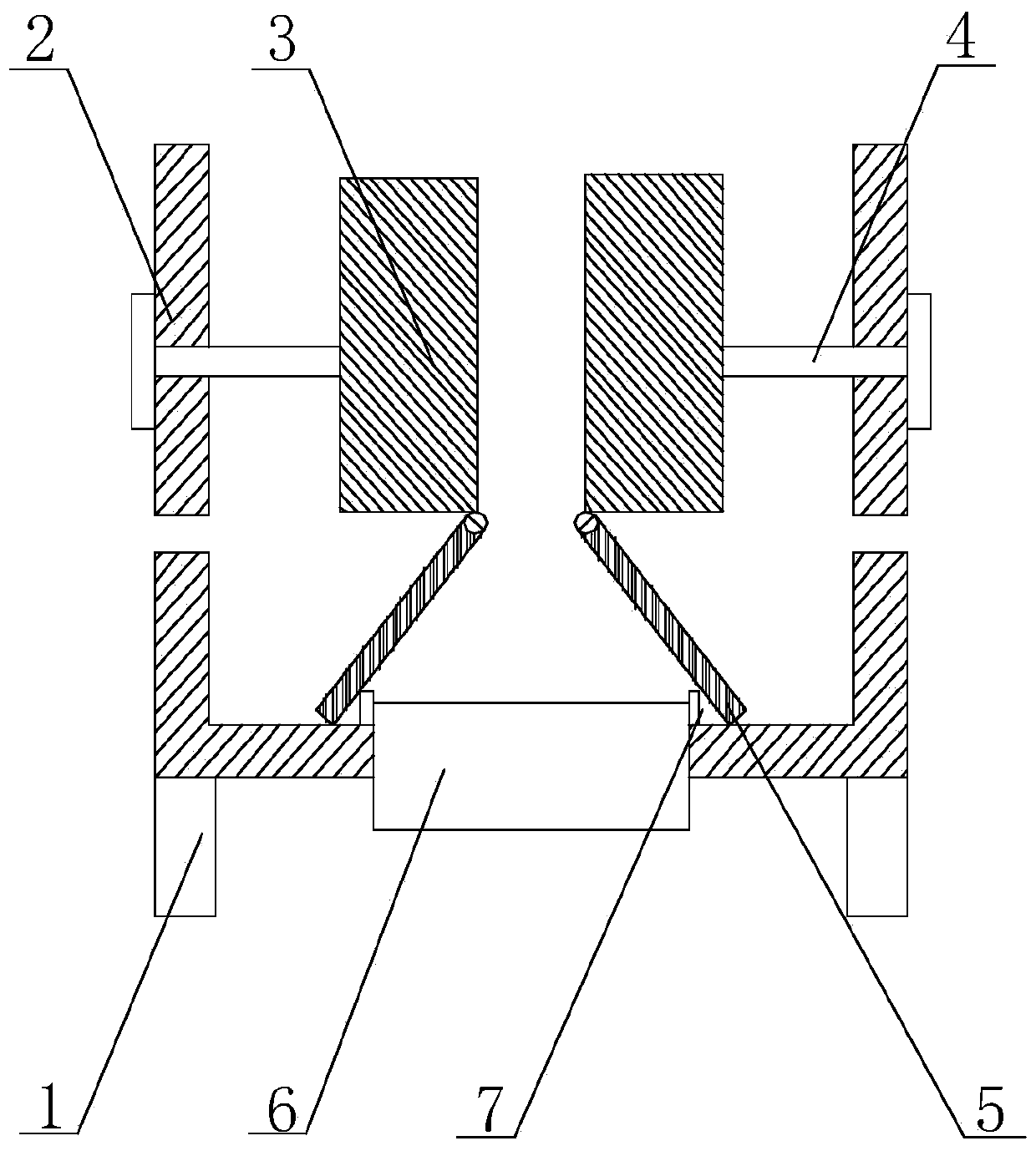

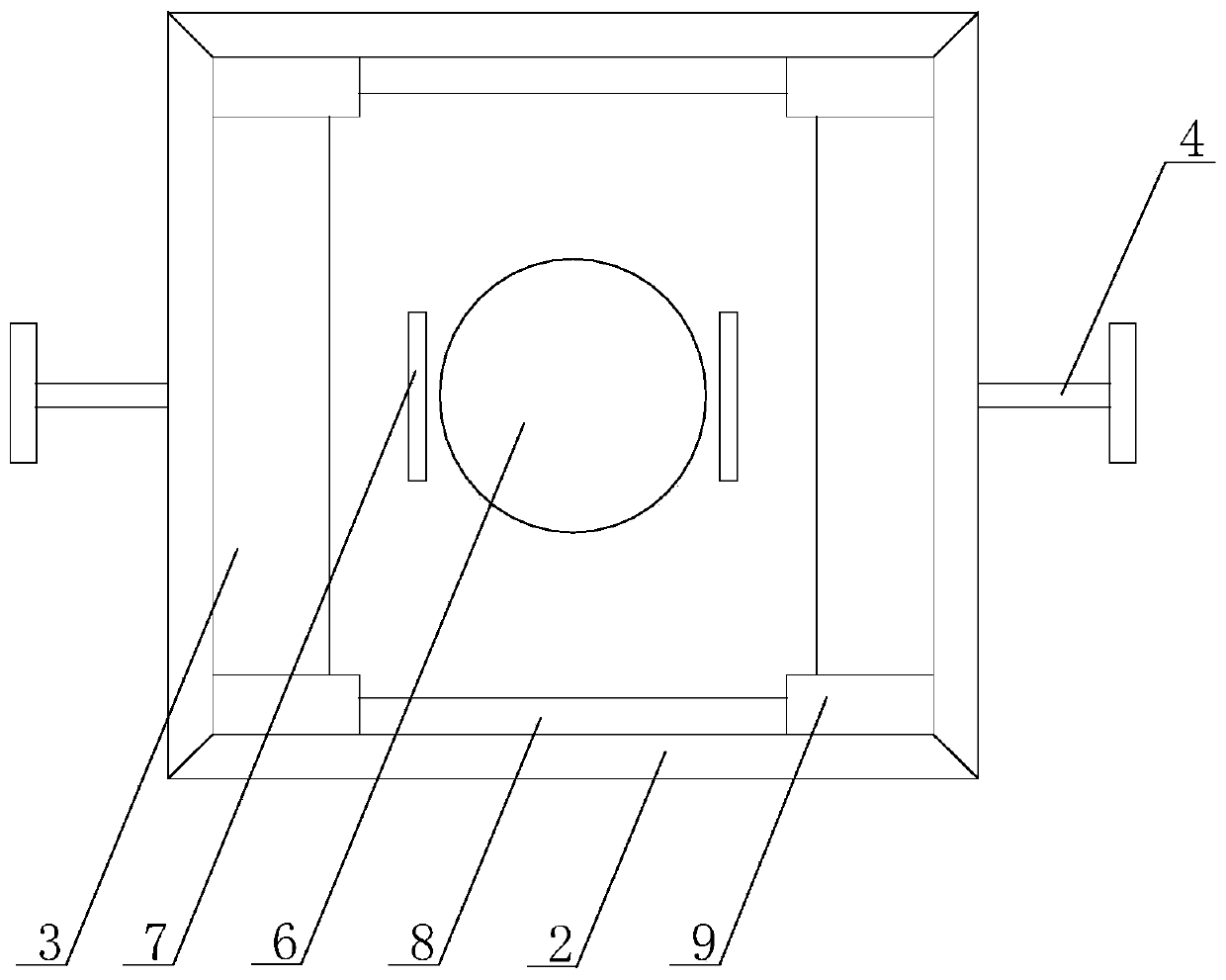

[0026] Such as Figure 1 to Figure 3 The air duct variable radiator shown in the figure includes a housing 2 with an upward opening, a supporting column 1 is arranged under the housing 2 , and a cooling fan 6 is arranged at the bottom of the housing 2 , and the air outlet of the cooling fan 6 is located inside the housing 2 , the two parallel inner walls of the housing 2 are provided with guide rails 8, the guide rails 8 are parallel to the horizontal plane, and also include two parallel moving plates 3, the moving plates 3 are located above the cooling fan 6, and the two ends of the moving plate 3 Both are fixed with a slider 9, the slider 9 is matched with the guide rail 8, the side of the moving plate 3 is fixed with an operating rod 4, and the operating rod 4 moves through the side of the housing 2 to the outside of the housing 2; the lower part of the moving plate 3 A rotating plate 5 is hinged on the surface; an elongated slot is provided on the inner wall of the housing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com