Indexable annular blade

A blade and ring technology, which is applied in the field of indexable ring blades, can solve the problems of reducing the cutting effect of the blade, reducing the service life of the blade, and cutting the knife, so as to achieve convenient and simple production of the knife body, improve installation reliability, and high positioning reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

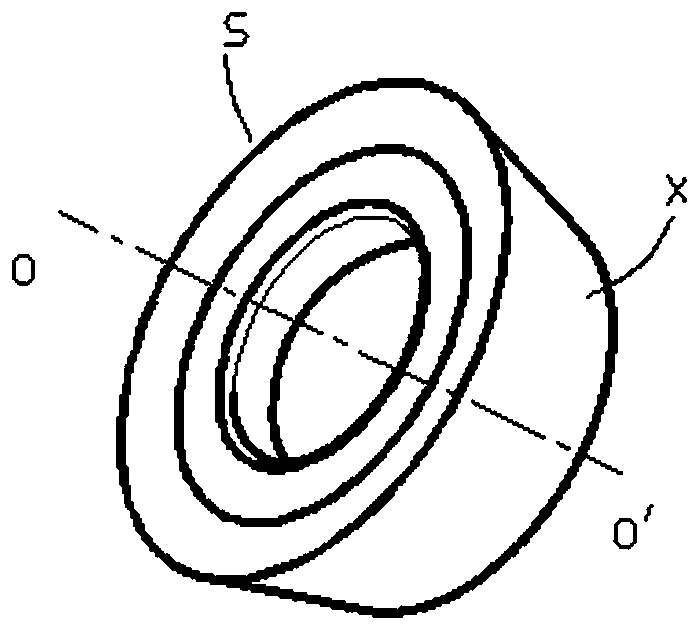

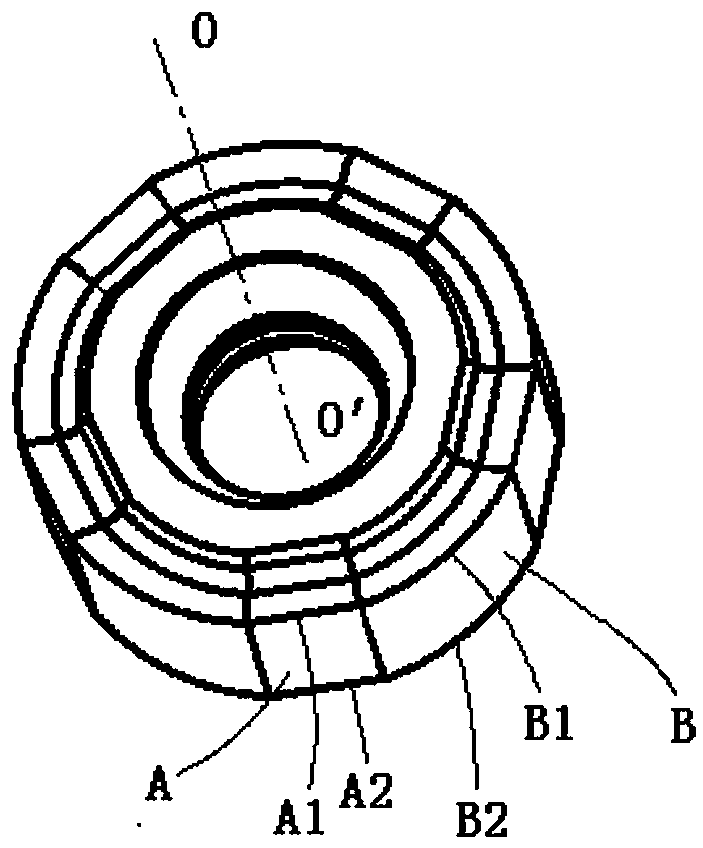

[0019] There are annular cutting edges on the upper or upper and lower sides of the indexable annular blade. The upper and lower peripheries are composed of arc lines and non-arc lines alternately. , The lower circular arc line is formed alternately by the curved surfaces of the sides.

[0020] The cutting edge projections of all the arc segments of the blade appear as different parts of the same complete circle on the plane perpendicular to the central axis of the blade, and the projections of the non-arc cutting edges appear as straight lines on the plane perpendicular to the central axis of the blade. The arc length of each arc segment is longer than the length of adjacent non-arc lines. The number of cutting edge arc segments is equal to the number of non-arc segments.

[0021] The cutting edge of the blade has several segments of circular arc and straight line, which are arranged at intervals to form a ring-shaped cutting edge; the structure of the blade flank is compose...

Embodiment 2

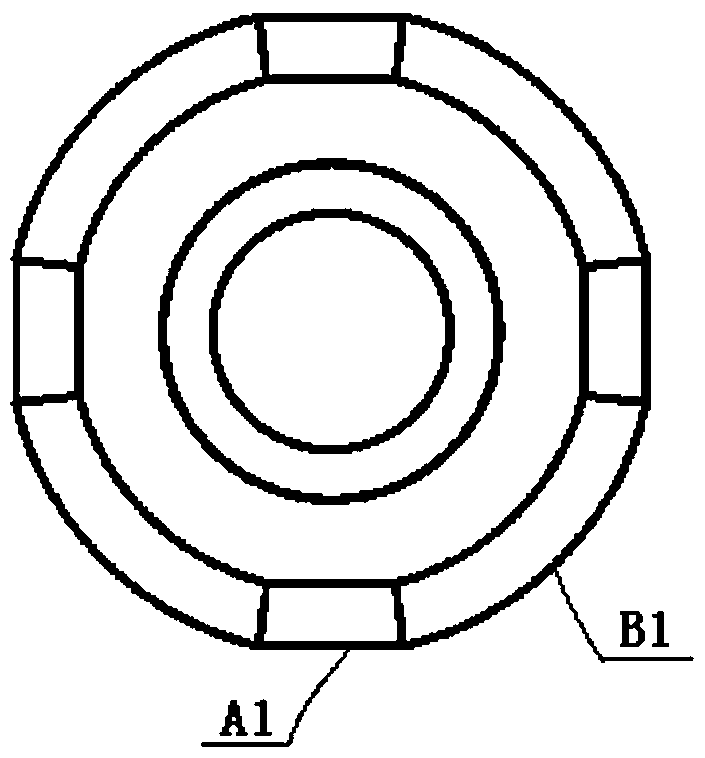

[0024] The indexable annular blade has an annular cutting edge on one side. The edge of the cutting edge and the annular blade edge are composed of arc lines and straight lines. The curved surfaces of the sides are formed alternately.

[0025] The arc length of each segment of arc is longer than that of adjacent straight lines. The number of edge arc segments is equal to the number of straight segments.

[0026] The cutting edge of this blade has several segments of circular arc and straight line, which are arranged at intervals and form an annular cutting edge; noodle.

[0027] by Figure 4 For example, a single-sided annular blade takes OO' as the axis, and has only one layer of cutting edges. B1 is the cutting edge of the circular arc segment, and the adjacent A1 is the cutting edge of the straight segment, and the arc-shaped surface of the B segment corresponds to the cutting edge segment of B1. flank of the adjacent

[0028] The plane of segment A is the flank face c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com