Fuel filter

A fuel filter and filter element technology, which is applied to fixed filter element filters, instruments, filtration separation, etc., can solve the problem of low filtration accuracy, water separation efficiency and dust holding capacity of fuel filters, and inconvenient installation and disassembly , complex circuit structure and other issues, to achieve the effect of high service life, high structural strength and high filtering accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] It should be understood that the specific embodiments described here are only used to explain the present invention, and are not intended to limit the present invention.

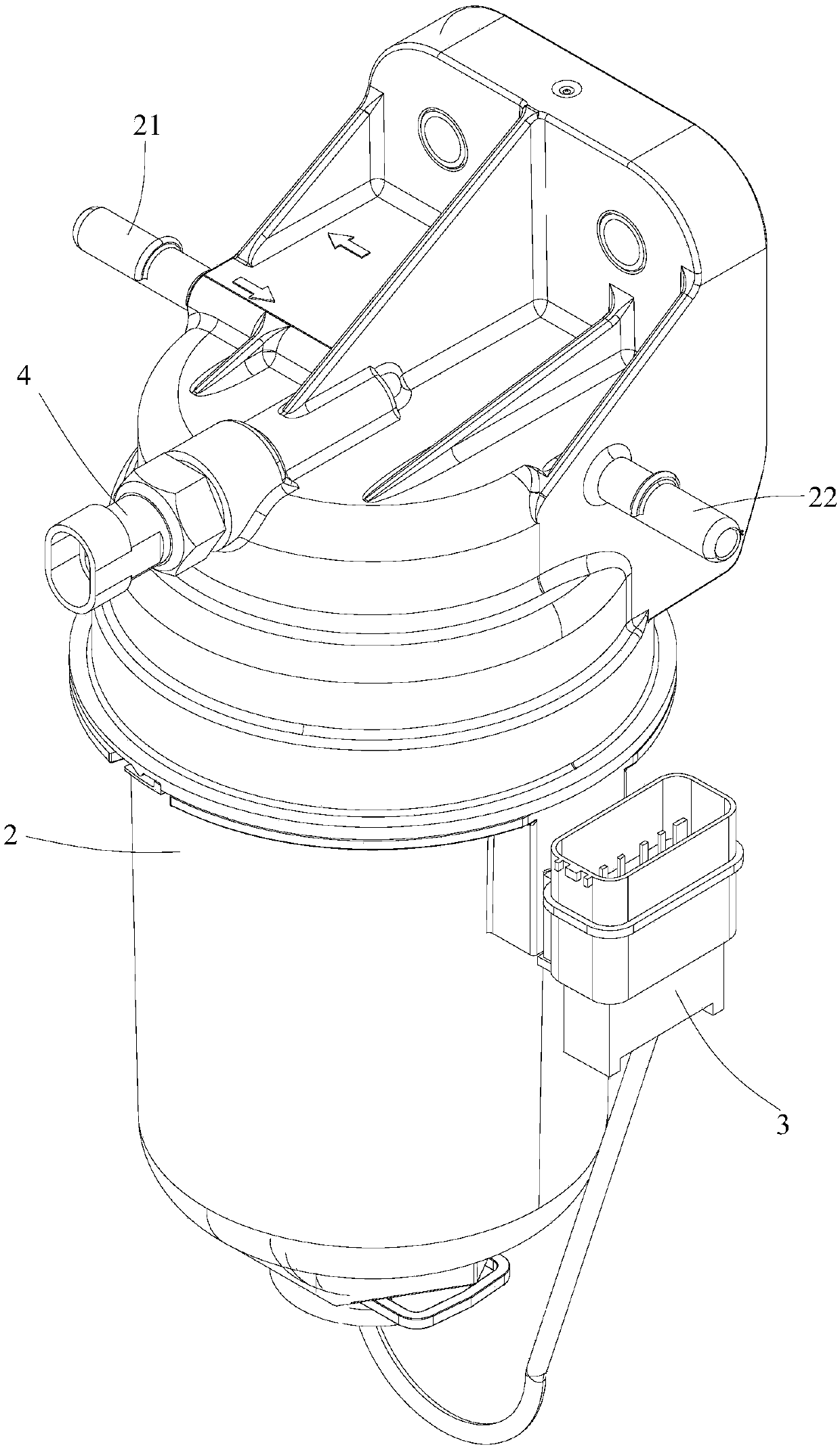

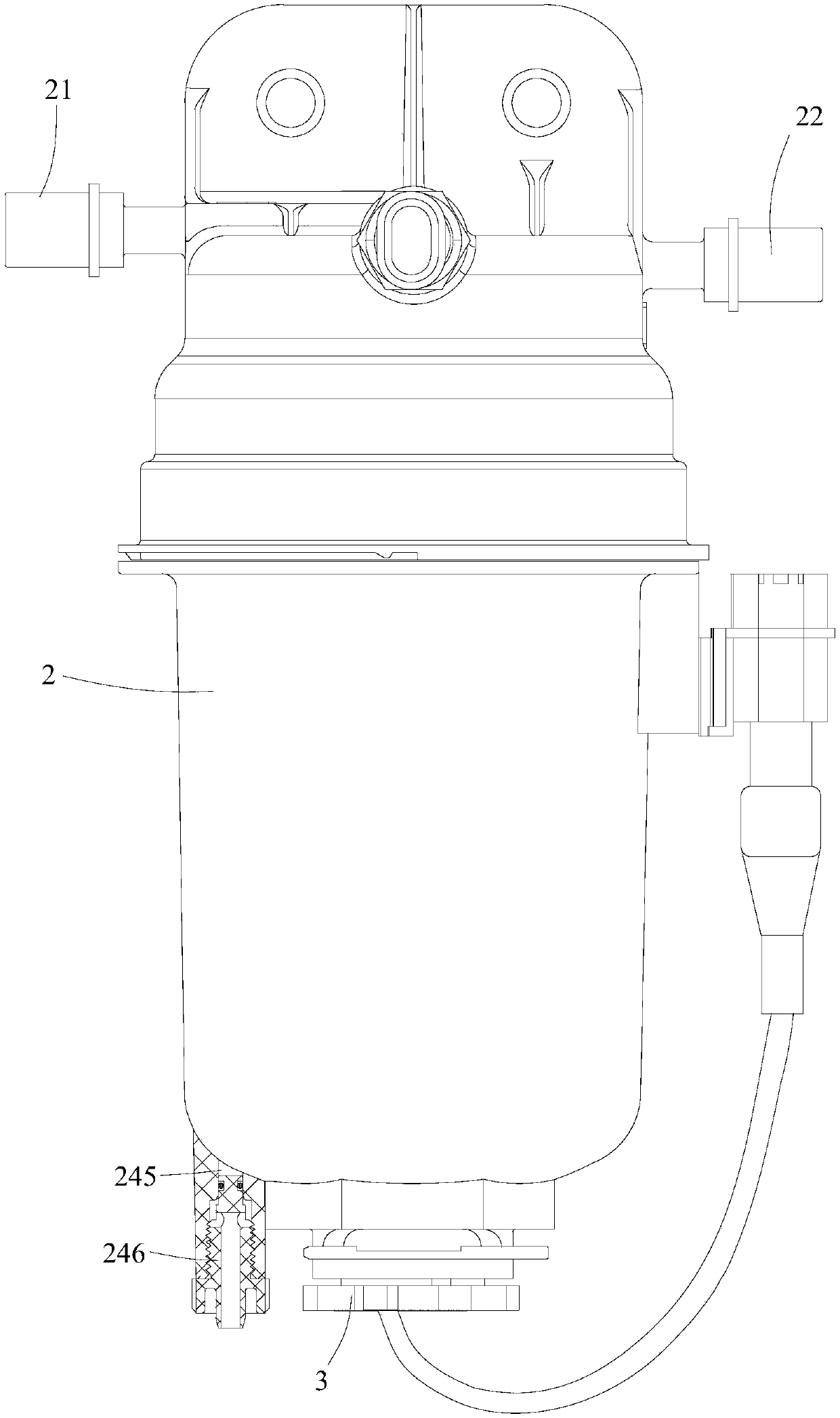

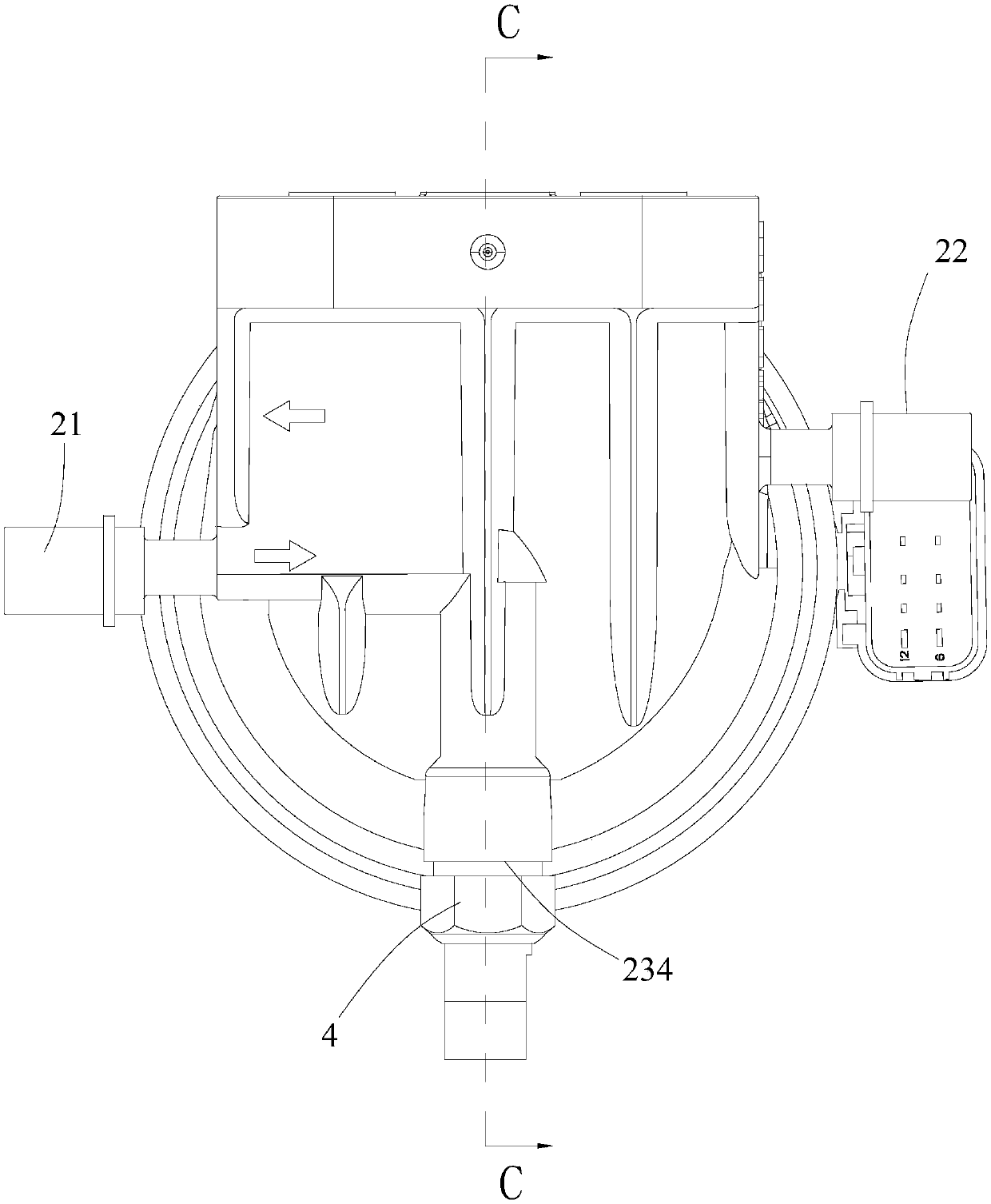

[0029] Such as Figure 1 to Figure 11 One embodiment of the fuel filter of the present invention is shown. In this embodiment, the fuel filter includes a housing 2, a combination sensor 3 and a filter element 1 disposed in the housing 2, and the housing 2 is provided with an oil inlet pipe 21 and an oil outlet pipe 22.

[0030] refer to Figure 8 to Figure 11 , the filter element 1 includes a cylindrical filter paper 11 folded in a zigzag shape, an inner net 12, an upper cover 13 and a lower cover 14, the inner net 12 is inserted in the tubular filter paper 11, and the inner net A filtering space 121 is formed inside the filter 12, the upper cover 13 and the lower cover 14 are respectively fixed on the two ends of the cylindrical filter paper 11, and the upper cover 13 is provided with an oil supply...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com