Full-automatic terminal pressure-welding device for super-long lead wire

A terminal crimping and fully automatic technology, which is applied in the direction of connection, connection by deformation, line/collector parts, etc., can solve problems such as inability to straighten, small size of equipment, and stretching length of wires that cannot meet the requirements. Achieve the effect of fully automatic production, simple and convenient use, and scientific and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] A fully automatic terminal crimping equipment for super-long wires of the present invention will be further described in detail below in conjunction with specific embodiments and accompanying drawings.

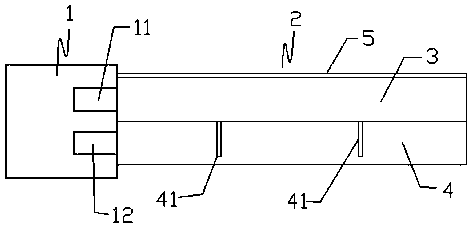

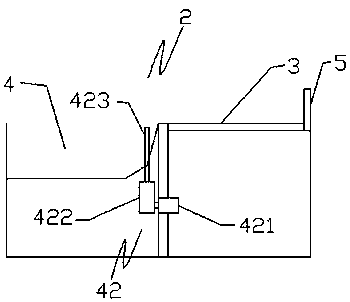

[0015] Such as figure 1 and figure 2 As shown, in a preferred embodiment, an ultra-long wire automatic terminal crimping equipment of the present invention includes a fully automatic terminal machine 1, and also includes a wire guiding device 2, and the wire guiding device 2 and the fully automatic terminal machine 1 connected, and set on the side of the product exit of the automatic terminal machine 1; the wire guiding device 2 includes a conveying area 3 and a finished product stacking area 4, and the finished product stacking area 4 is provided with at least two guide grooves 41, and the guiding A guide mechanism 42 is provided under the groove 41; the automatic terminal machine 1 includes a cutting station 11 and a terminal crimping station 12, the transfer area 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com