Cable head scraping system

A cable head and cable technology, applied in circuits, electrical components, circuit/collector parts, etc., can solve problems such as time-consuming and labor-intensive, and achieve the effect of speeding up docking, speeding up work, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

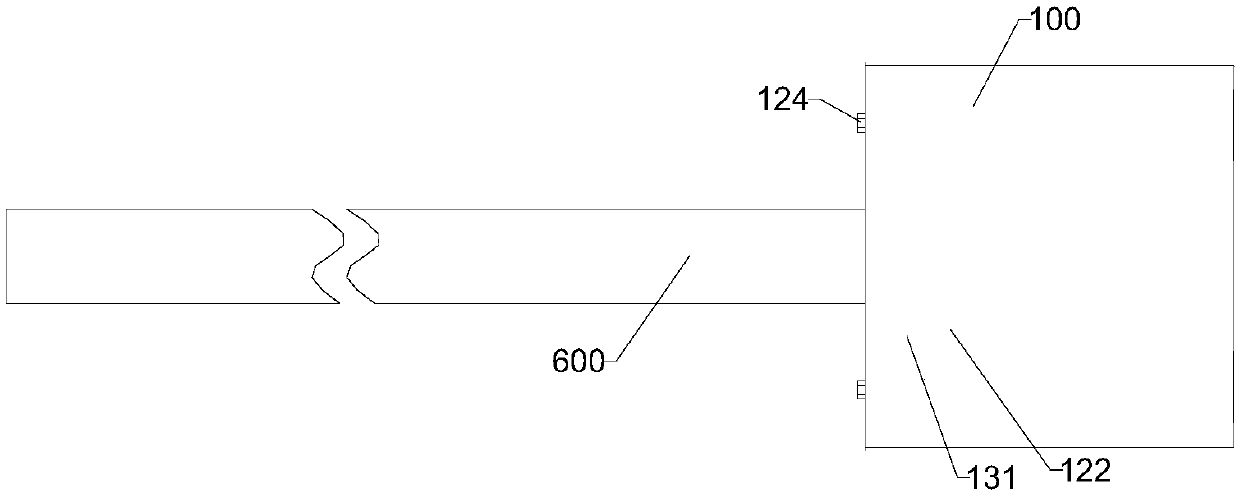

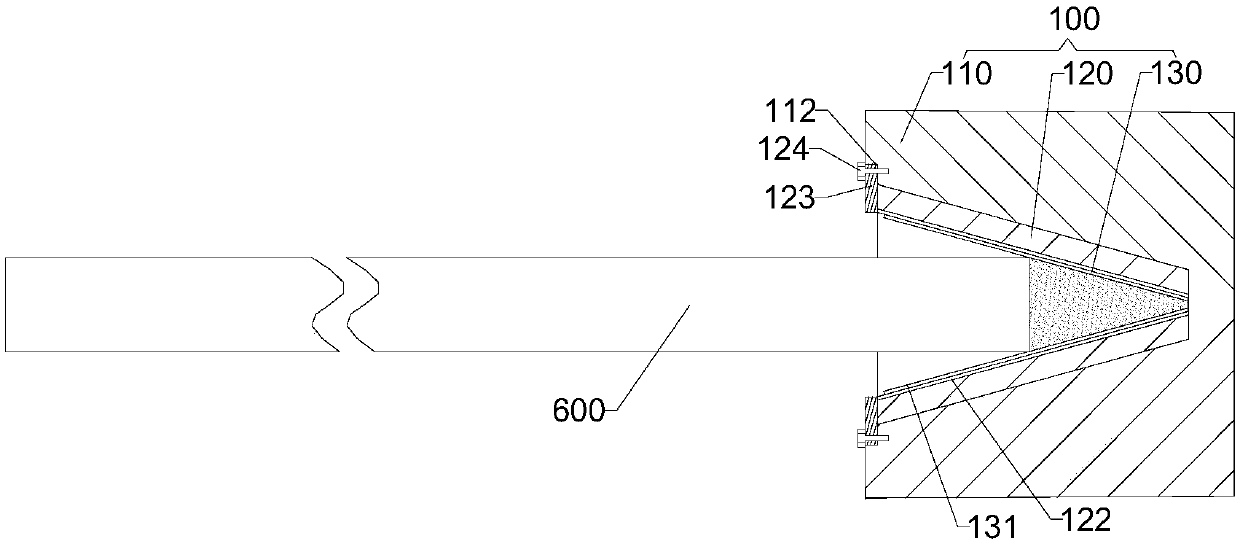

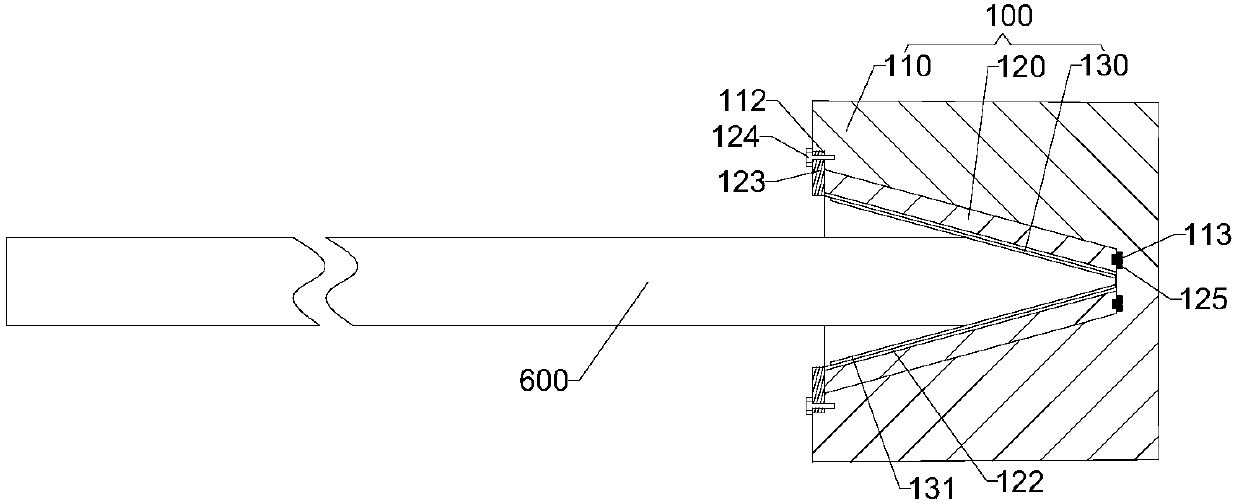

[0041] Embodiment 1, with reference to Figure 1 to Figure 10 .

[0042]The special spiral scraper 100 for the cable head provided in this embodiment (hereinafter referred to as the special spiral scraper 100 ). Such as figure 1 and figure 2 As shown, a helical scraper body 110 , a helical scraper sleeve 120 and a knife 130 are included. The spiral scraper cover 120 is mounted on the spiral scraper body 110 . The spiral scraper sleeve 120 is provided with a conical processing hole 121 through which two ends pass through, and the cutter 130 is disposed in the conical processing hole 121 . The cutter 130 is provided with an elongated scraping edge 131 , and the extending direction of the elongated scraping edge 131 is parallel to the extending direction of the generatrix corresponding to the conical machining hole 121 .

[0043] When the cable 600 of the overhead transmission line and the distribution line are broken, it involves the docking of the cables 600 heads of vari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com