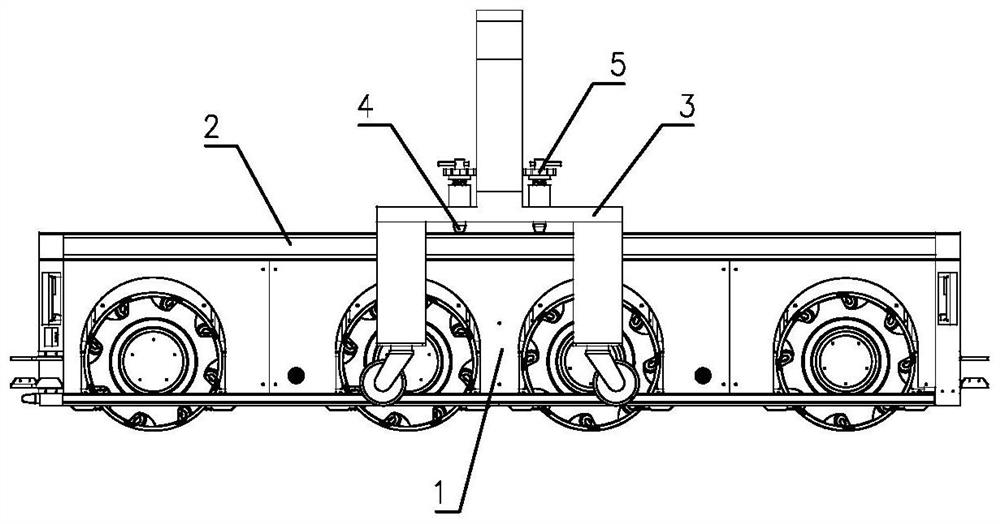

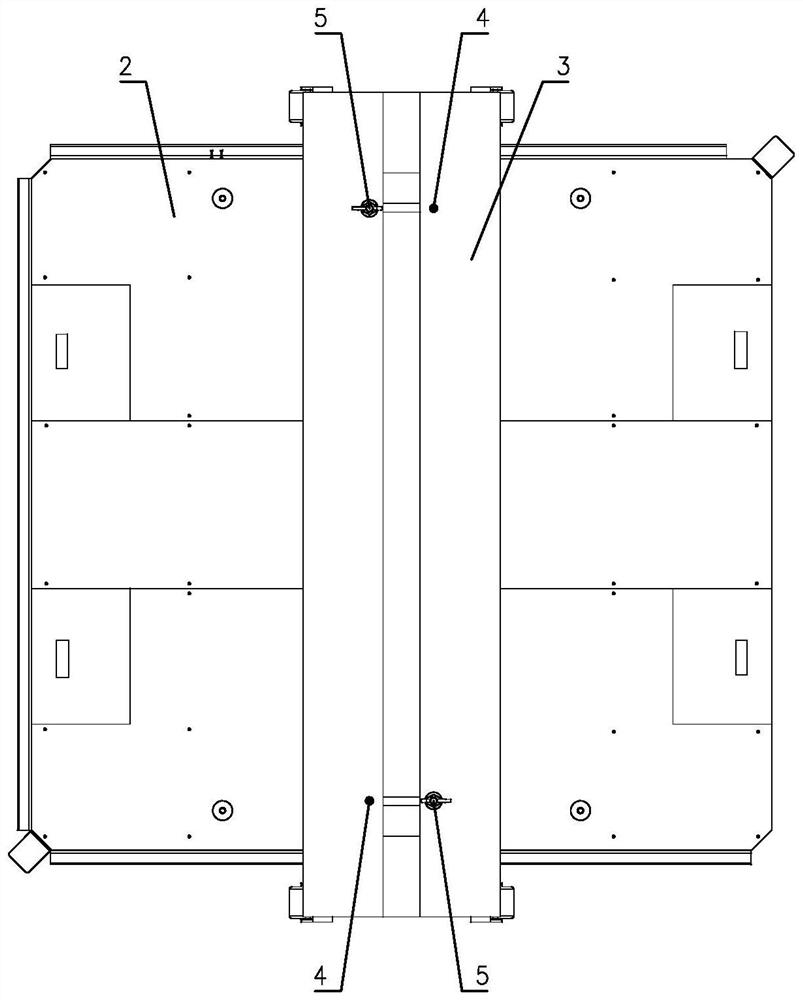

AGV jacking butt-joint locking system

A technology for jacking up and docking platforms, applied in the direction of lifting devices, etc., can solve problems affecting safety and reliability, unreliable locking, high positioning accuracy requirements, etc., and achieve the effect of simple structure, high safety, and fast docking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] First of all, it needs to be explained that the orientation words such as up, down, left, right, front, and back described in the present invention are only described according to the accompanying drawings, so as to be easy to understand, and are not intended to limit the technical solution and scope of protection of the present invention. .

[0034] Such as Figure 1 to Figure 18 Shown is a specific embodiment of an AGV jacking and docking locking system of the present invention, including an AGV car 1, a docking platform 2 and a shelf 3, and the docking platform 2 is installed on the AGV car 1 through a plurality of elevators, and on the docking platform 2 Two positioning holes 21 and two limiting holes 22 are provided, so that the limiting holes 22 are rectangular holes, and limiting grooves 23 are respectively provided on the lower side of the docking platform 2 and on both sides of the long sides of the limiting holes 22. The shelf 3 is provided with a support pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com