Self-propelled green hedge trimmer and use method

A hedge trimmer, self-propelled technology, applied in the field of hedge trimmers, can solve problems such as inconvenient operation, difficult trimming of sloped hedge greening trees, and inflexible adjustment of the operating angle of the pruning knife, so as to achieve fast transition speed and improve trimming Efficiency, the effect of reducing the cost of manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

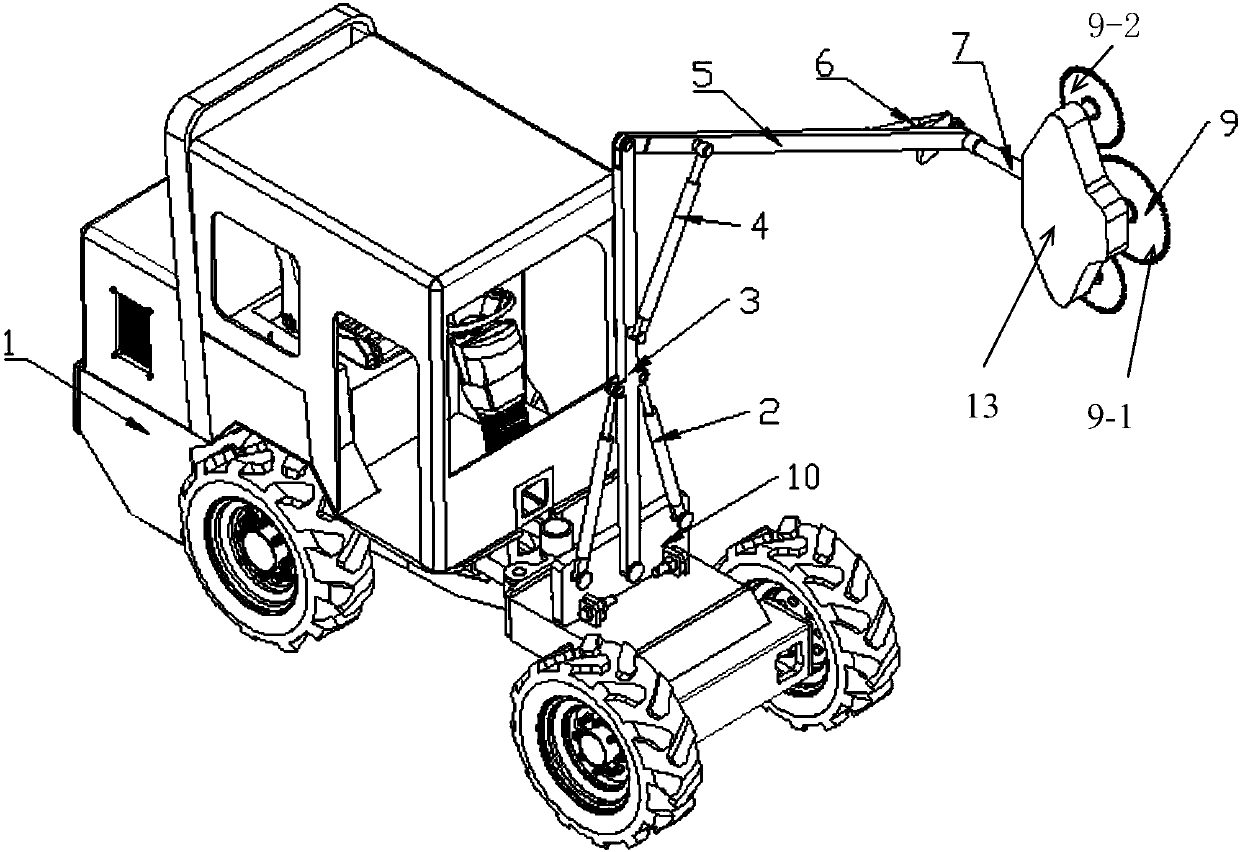

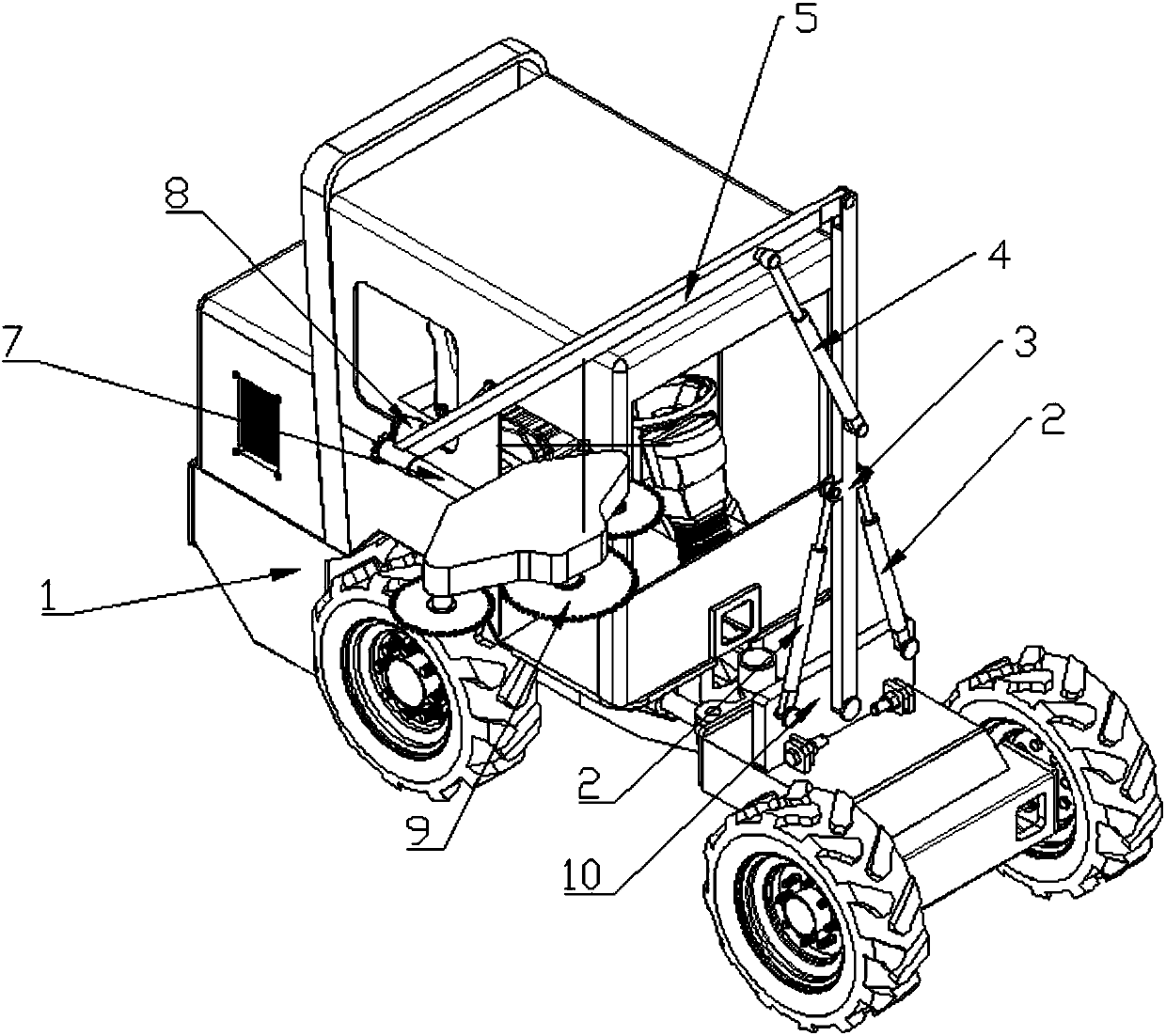

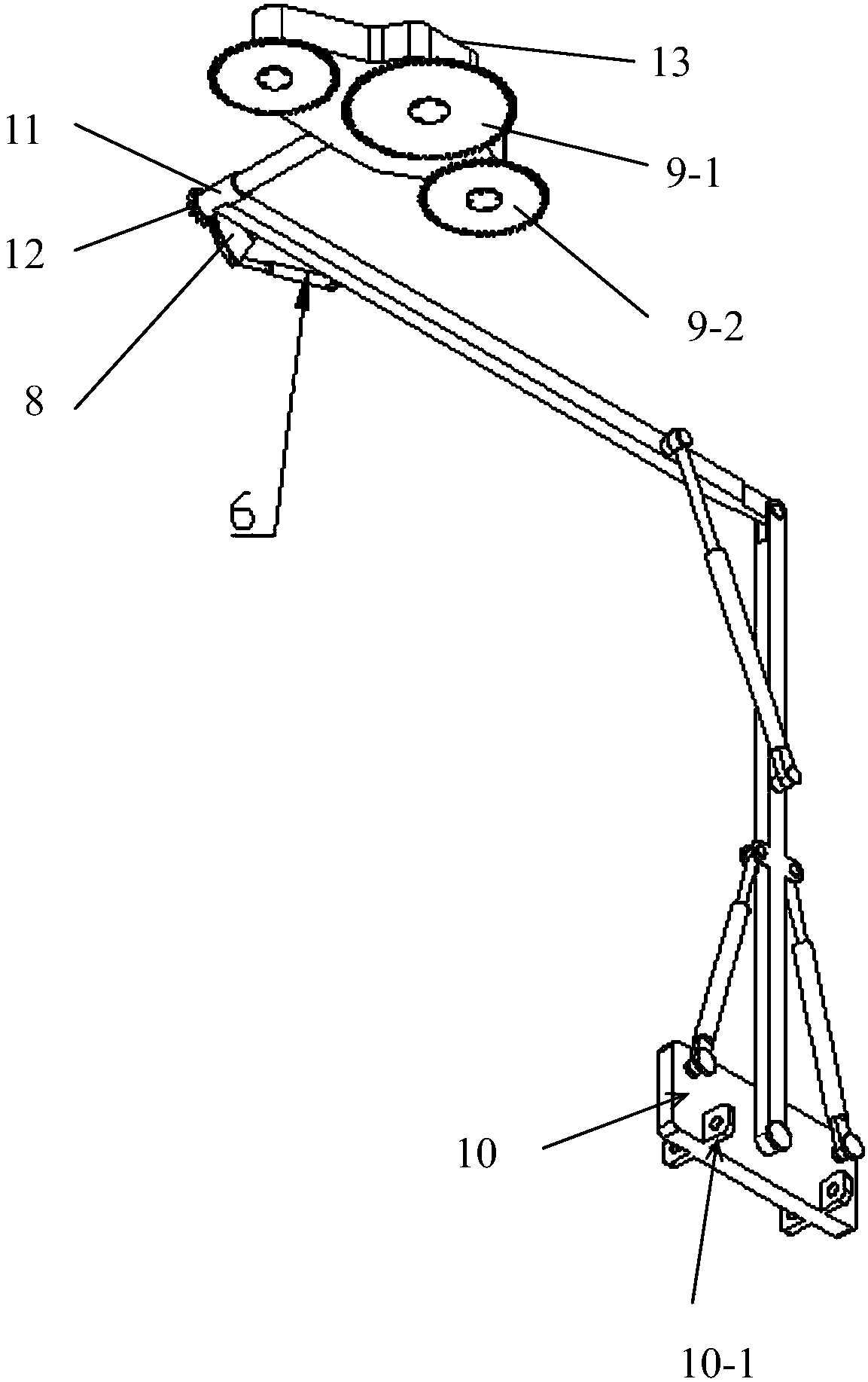

[0015] Specific implementation mode one: as Figure 1~5 As shown, a kind of self-propelled hedge trimmer described in this embodiment comprises a carrying vehicle 1 and a trimming device placed on the carrying vehicle 1, and the carrying vehicle 1 is connected with the base 10 of the trimming device (the carrying vehicle and the base can be connected by bolts fixed together); the pruning device includes a base 10, two first-stage hydraulic cylinders 2, a long arm rotating arm 3, a second stage hydraulic cylinder 4, a middle arm rotating arm 5, a third stage hydraulic cylinder 6, and a short arm rotating Arm 7, fan-shaped tooth 8 and saw blade 9, the lower end of the long-arm rotating arm 3 is hinged on the base 10 (that is, the long-arm rotating arm 3 can swing left and right along the base 10), and the two first-stage hydraulic cylinders 2 are arranged in a figure-eight shape. On both sides of the lower part of the long-arm rotating arm 3, the end of the piston rod of each fi...

specific Embodiment approach 2

[0017] Specific implementation mode two: as Figure 1~5 As shown, in the self-propelled hedge trimmer described in this embodiment, the saw blade 9 is installed on the saw disc 13, and the saw disc 13 is fixed on the end of the short-arm turning arm 7, and the saw blade can be replaced. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0018] Specific implementation mode three: as Figure 1~5 As shown, the saw disc 13 in this embodiment is fan-shaped, and the middle part of the peripheral edge of the saw disc 13 is fixed on the end of the short arm turning arm 7 . Other compositions and connections are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com