Improved mailbox device

A letterbox and base technology, applied in the field of improved letterbox devices, can solve the problems of complex structure, low work efficiency, low painting efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

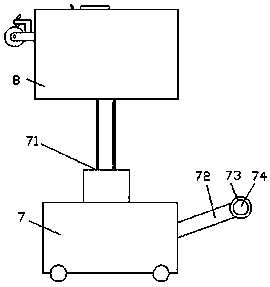

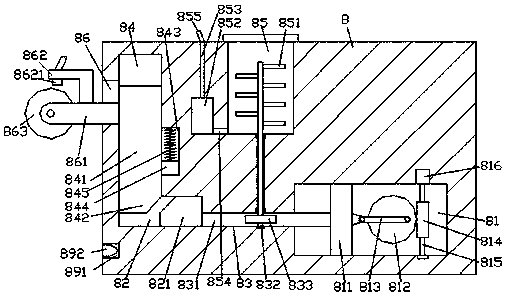

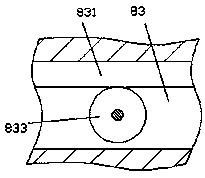

[0017] like figure 1 , figure 2 and image 3 As shown, an improved letterbox device of the present invention includes a base body 8 installed on the upper side of the trolley 7 through an oil pressure shrinking cylinder 71, and an inclined push rod 72 is fixedly installed on the upper position of the right end surface of the trolley 7, The top of the oblique push rod 72 is fixedly equipped with a hand-held rod 74 that is expanded front and rear, and the front and rear ends of the hand-held rod 74 are covered with hand-protecting rubber sleeves 73, and the inside of the base body 8 is provided with a first hole 81. The inner wall of the base body 8 on the left side of the first hole 81 is provided with a second hole 82 , and between the second hole 82 and the first hole 81 is a hole that runs through the base. The inner wall of the body 8 is connected with a connecting hole 83 provided, and the inner top wall of the left section of the second hole 82 is communicated with a f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com