Automatic riveting device

An automatic riveting and riveting technology, which is applied in heat exchange equipment and other directions, can solve the problems of time-consuming and labor-intensive riveting accuracy cannot be guaranteed, and low production efficiency, so as to improve riveting accuracy, improve riveting efficiency, and save manpower cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

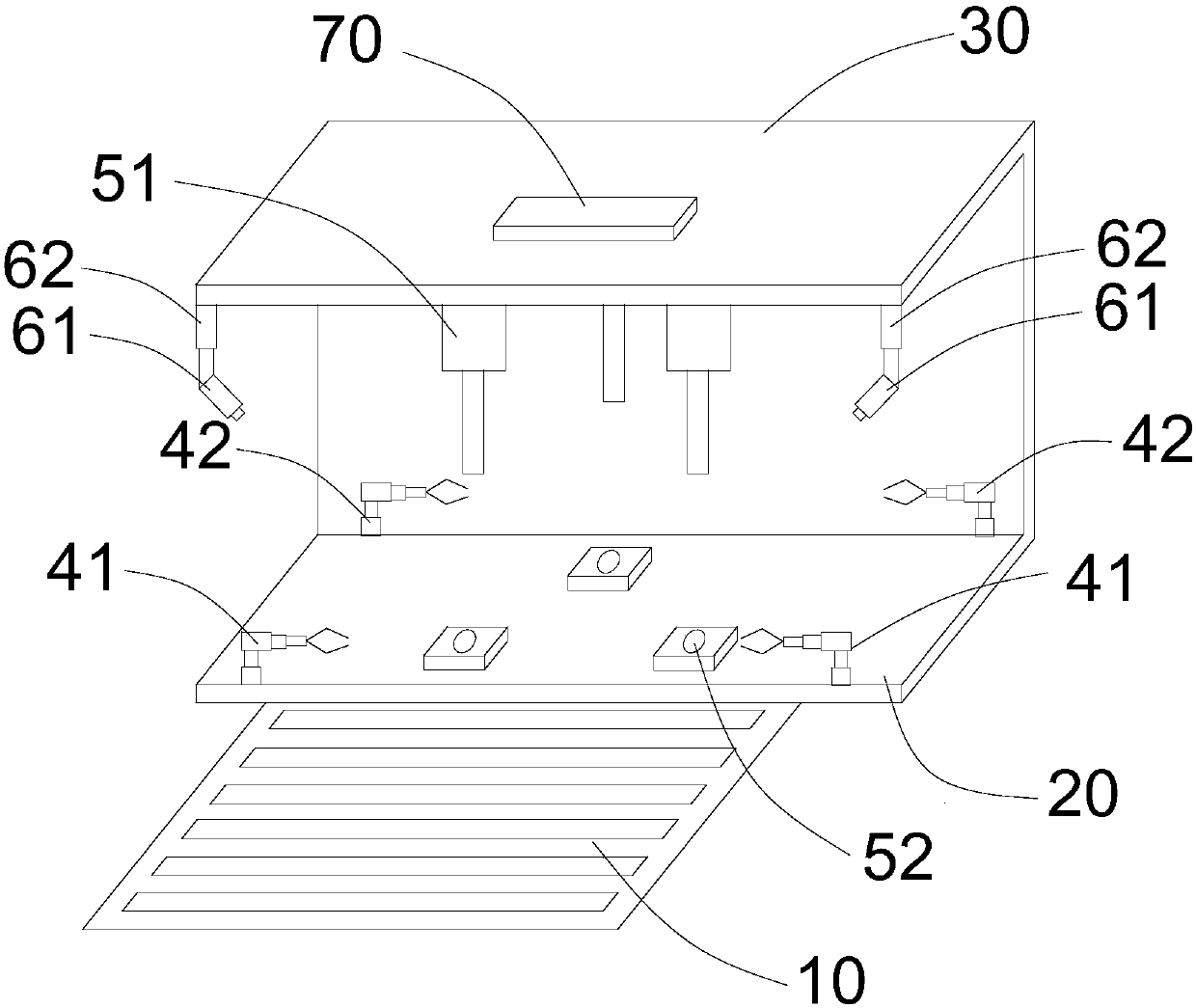

[0015] like figure 1 As shown, the automatic riveting device of the present invention includes a conveyor belt 10, a riveting platform 20 and an upper cover 30, the conveyor belt 10 is connected to the riveting platform 20, and the upper cover 30 is fixedly installed on the riveting Platform 20, the upper cover plate 30 is equipped with a riveting head 51, and the riveting platform 20 is fixedly equipped with a riveting lower die 52 matching the riveting head 51, and an upper die 52 is installed on the riveting platform 20. The material manipulator 41 and the blanking manipulator 42, the upper cover plate 30 is fixedly equipped with a positioning camera 60, the camera 60 and the upper cover plate 30 are connected by a telescopic rod 62, and the automatic riveting device also includes a control 70, the loading manipulator 41, the unloading manipulator 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com