A multi-metal stepped composite casting device and method

A composite casting and stepped technology, which is applied in the field of multi-metal stepped composite casting devices, can solve the problems of low productivity and poor interface quality, and achieve the effects of reasonable structure, quality assurance, and avoidance of oxidation and gas entrapment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

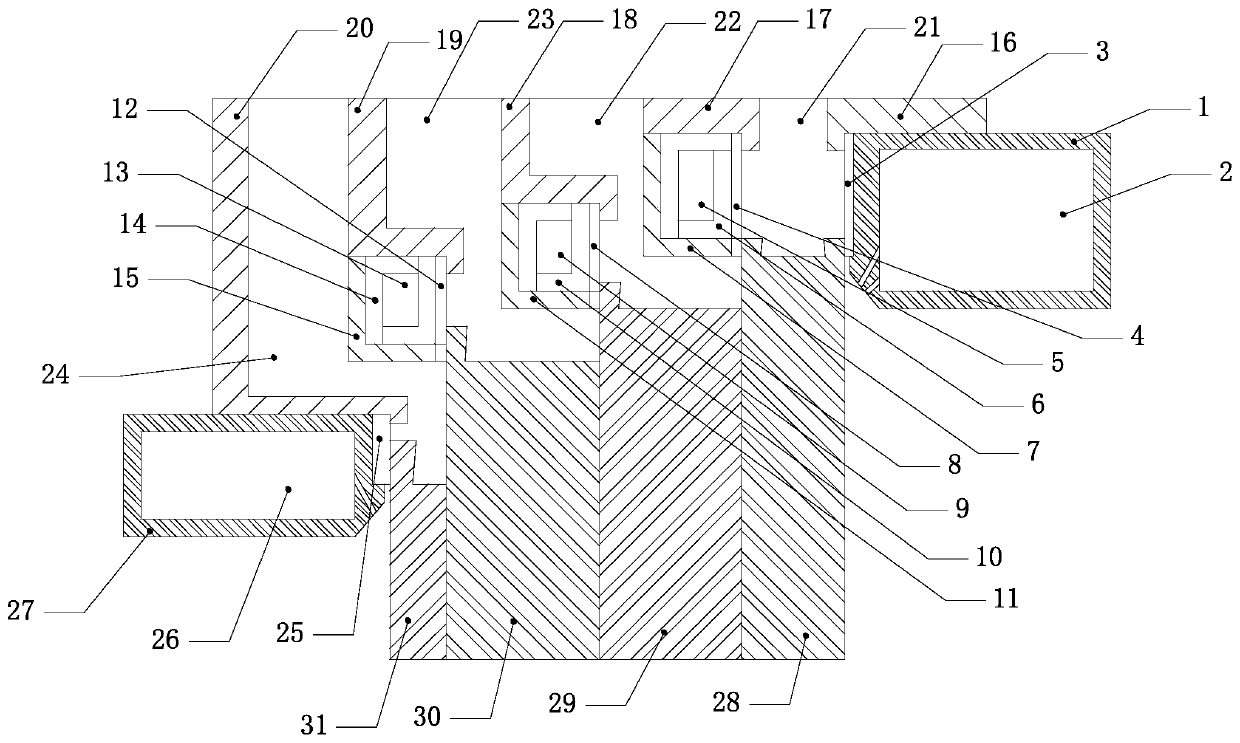

[0042] In Example 1, the first alloy is 3003 aluminum alloy, the second alloy is 6061 aluminum alloy, the third alloy is 7050 aluminum alloy, the fourth alloy is 4045 aluminum alloy, and the ingot size is 400 (width) × 200 (thickness) × 2000 (length) mm, the thickness of the four layers are 40, 70, 70, 20mm respectively.

[0043] The step casting method of the multi-metal layered composite ingot, the specific steps are as follows:

[0044] Step 1: Melting of the alloy

[0045] The four kinds of alloys were smelted, refined and kept in four smelting furnaces respectively, and kept warm for later use. Among them, the pouring temperature of 3003 aluminum alloy was controlled at 710°C (the liquidus line of 3003 aluminum alloy was 658°C, and the solidus line was 646°C). The pouring temperature of 6061 aluminum alloy is controlled at 740°C (the liquidus line of 6069 aluminum alloy is 652°C, and the solidus line is 533°C), and the pouring temperature of 7050 aluminum alloy is contro...

Embodiment 2

[0050] In Example 2, the first alloy is 4032 aluminum alloy, the second alloy is 6069 aluminum alloy, the third alloy is 7075 aluminum alloy, the fourth alloy is high-purity aluminum, and the ingot size is 400 (width) × 200 (thick) × 2000 (length) mm, the thickness of the four layers are 20, 80, 80, 20mm respectively.

[0051] The step casting method of the multi-metal layered composite ingot, the specific steps are as follows:

[0052] Step 1: Melting of the alloy

[0053] The four kinds of alloys were smelted, refined and kept in four smelting furnaces respectively, and kept warm for later use. Among them, the pouring temperature of 4032 aluminum alloy was controlled at 730°C (the liquidus line of 4032 aluminum alloy was 570°C, and the solidus line was 517°C). The pouring temperature of 6069 aluminum alloy is controlled at 750°C (the liquidus line of 6069 aluminum alloy is 647°C, and the solidus line is 511°C), and the pouring temperature of 7075 aluminum alloy is controlle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com