Automatic coating equipment for storage battery case

A battery and shell technology, applied in the field of automatic coating equipment for battery shells, can solve the problems of low coating efficiency, poor coating effect, and inability to achieve battery shells, and achieve good coating effect, high work efficiency, and good effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

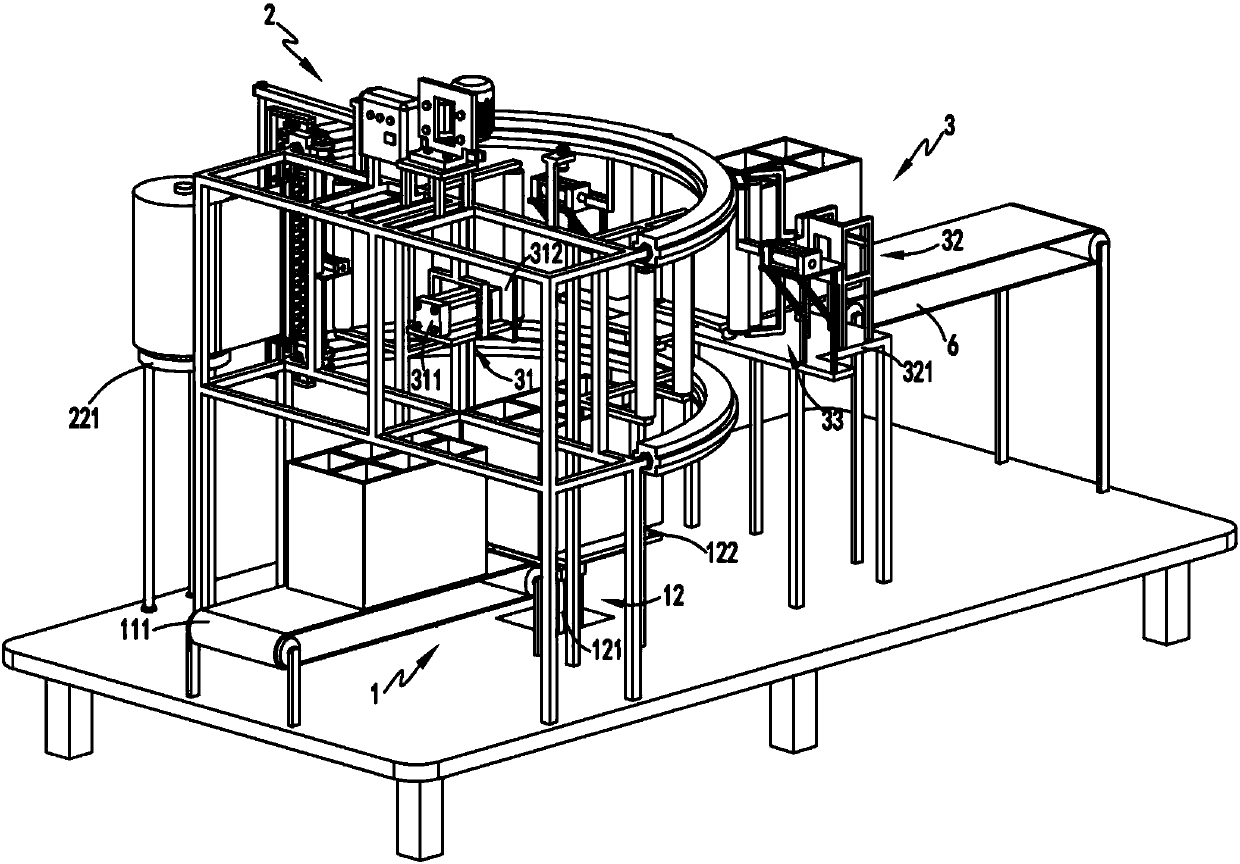

[0049] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 As shown, an automatic battery casing coating equipment includes a feeding part 1, and the feeding part 1 includes a horizontal conveying device 11 and a lifting device 12 arranged at the rear end of the horizontal conveying device 11;

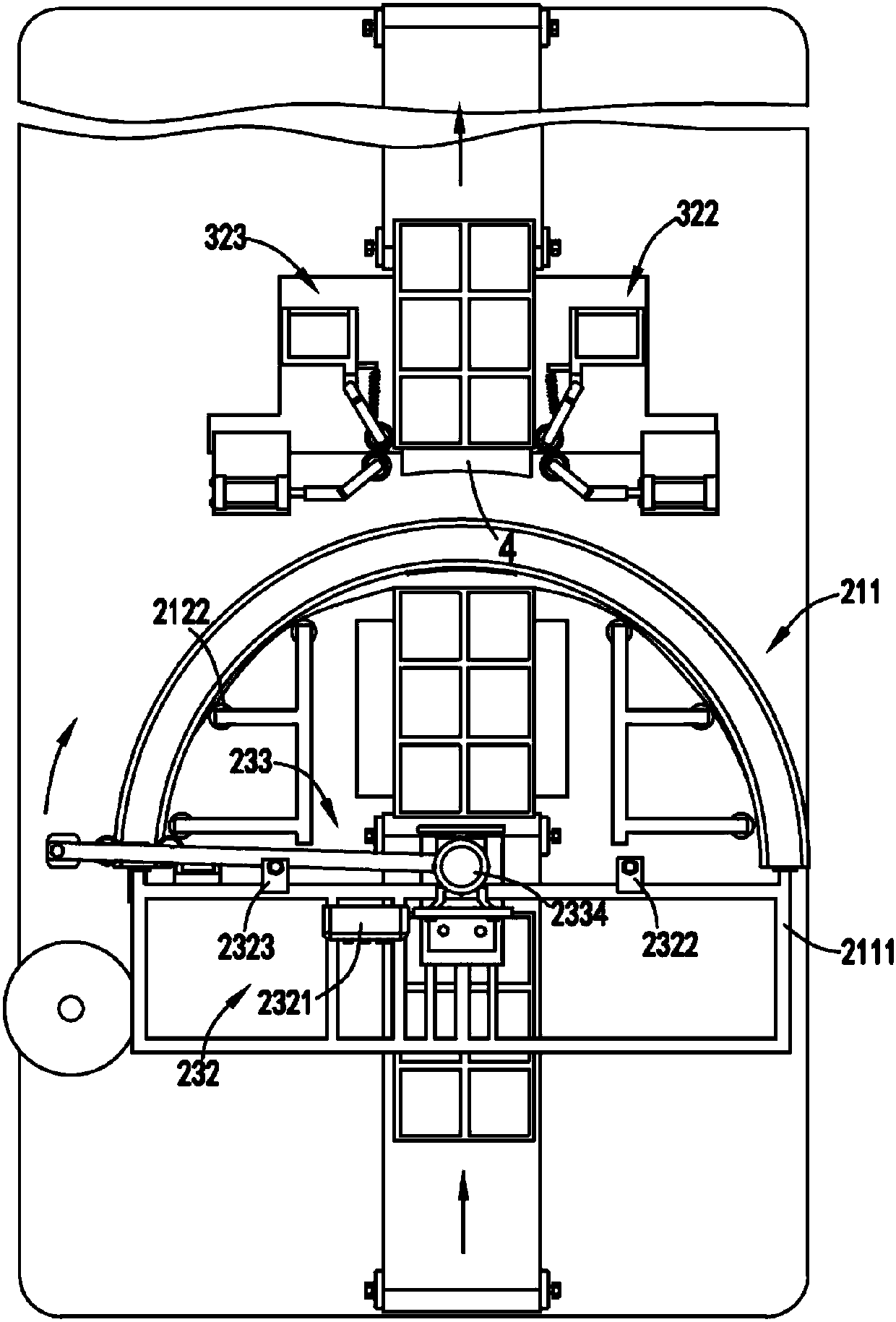

[0050] The film pulling part 2, the film pulling part 2 is arranged on the top of the lifting device 12, the film pulling part 2 includes a guide device 21, an unwinding device 22 arranged on one side of the guide device 21 and a pulling device arranged on the guide device 21 The film device 23, the film pulling device 23 is used to pull the end of the film 10 on the unwinding device 22 to move from one end of the guide device 21 to the other end;

[0051] The coating part 3, the coating part 3 includes a pushing device 31 for pushing the shell 20 transported by the lifting device 12 to move backward to complete the coa...

Embodiment 2

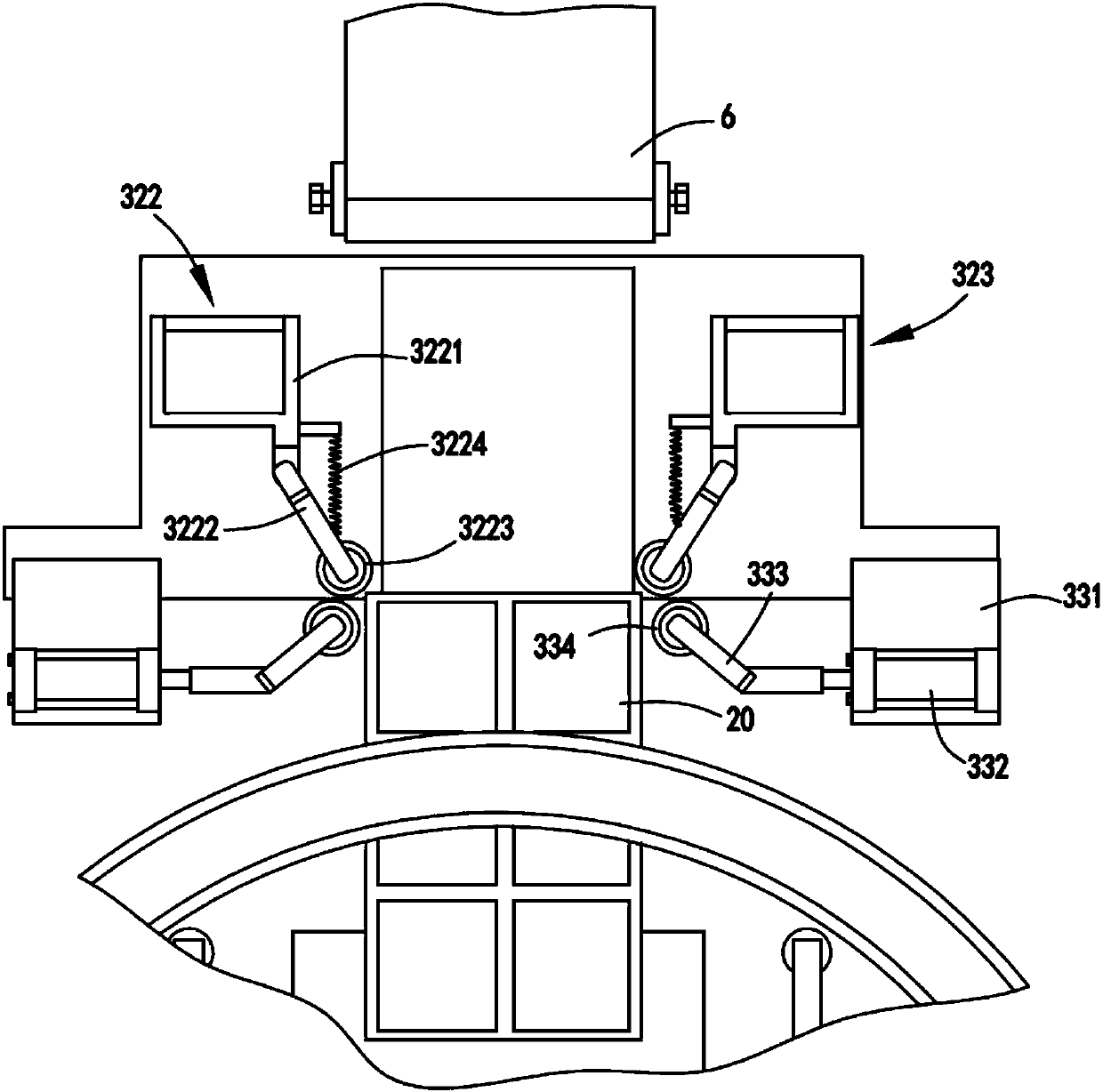

[0072] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between the second embodiment and the first embodiment is that further, the pushing device 31 includes a flat-push cylinder a311 fixed on the arc-shaped guide and slide mechanism 211 and a push cylinder a311 arranged at the end of the telescopic rod of the flat-push cylinder a311. board 312;

[0073] The rolling device 32 includes a supporting base 321 and a rolling mechanism a322 and a rolling mechanism b323 symmetrically arranged on the supporting base 321. The rolling mechanism a322 and the rolling mechanism b323 both include a turret 3221, which can be rotated The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com