Durable pellet feed adjuvant and its application

A pellet feed and durability technology, applied in application, animal feed, additional food elements, etc., can solve the problem of pig feed intake reduction, etc., to improve the feeding line is too long, improve durability, increase hardness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] A durable granular feed additive, comprising the following components in parts by weight: 700 parts of water-soluble lignin of 200-300 mesh, 100 parts of hydrated sodium calcium aluminosilicate, 100 parts of fine sugar below 100 mesh and 100 parts of mannan oligosaccharide share.

[0019] The preparation method of water-soluble lignin: take the wood cut within half a month, on the cross-section of the wood, take the center of the wood as the dot, and 1 / 3 of the wood radius as the radius, take the material in the circle as the raw material, add water to grind, and grind it into Slurry, use a 60-mesh sieve, filter to remove impurities on the sieve, adjust the dry matter content to 18-20%, add sulfur dioxide with a mass fraction of 0.1%, fully dissolve at 52°C, concentrate and dry at room temperature, concentrate and extract to obtain water-soluble sexual lignin.

[0020] Get 5 kilograms of durable pellet feed additives and add in 1000 kilograms of nursery pig pellet feed...

Embodiment 2

[0022] A durable granular feed additive, comprising the following components in parts by weight: 800 parts of water-soluble lignin of 200-300 mesh, 50 parts of sodium calcium aluminosilicate hydrate, 50 parts of fine sugar below 100 mesh and 100 parts of mannan oligosaccharide share.

[0023] Water-soluble lignin is the same as in Example 1.

[0024] Get 6 kilograms of durable pellet feed additives and add in the nursery pig pellet feed of 1000 kilograms.

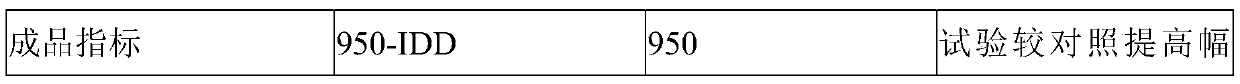

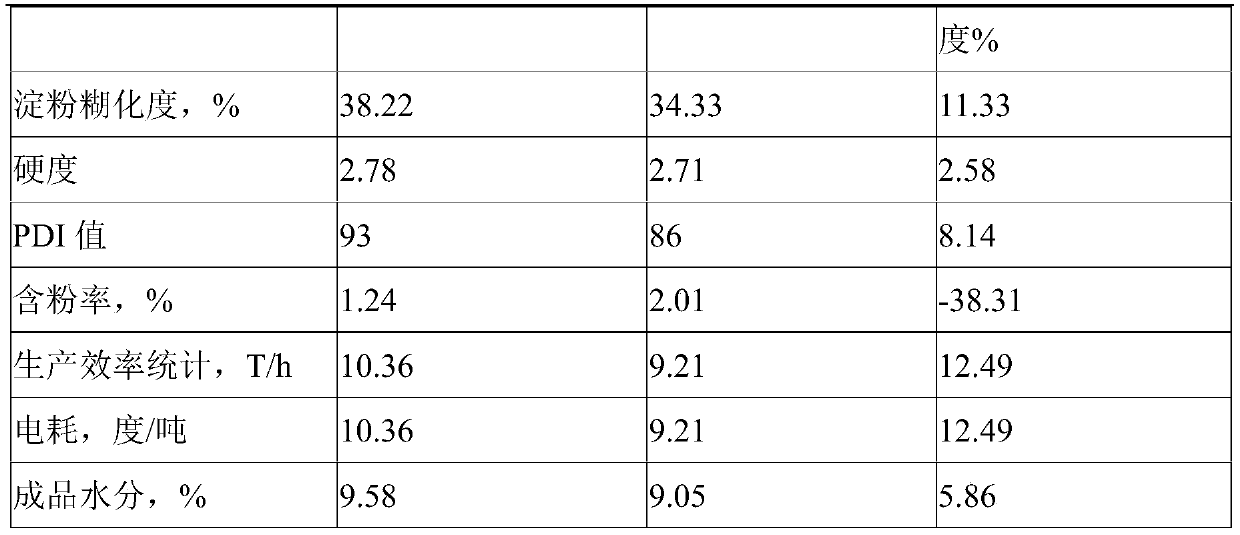

[0025] Application effect evaluation:

[0026] Bangji (Shandong) Agricultural Technology Co., Ltd. cooperated with the pig farm of Binzhou Zhongyu Group to conduct a comparative feeding test before and after adding granular adjuvants. The test results show that the addition of the durable granule feed additive of the present invention greatly improves the properties of the granules and significantly improves the feeding effect.

[0027] 1. Materials and methods

[0028] 1.1 Selection of test material: the test group is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com