Method for manufacturing longitudinal series of contact type microcircuit cards

A technology of microcircuit card and contact type, which is applied in the direction of lamination, lamination device, chemical instrument and method, etc., can solve the problem of no contact type microcircuit card, etc., and achieve less risk of accidental breakage, greater convenience, and better machinery The effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

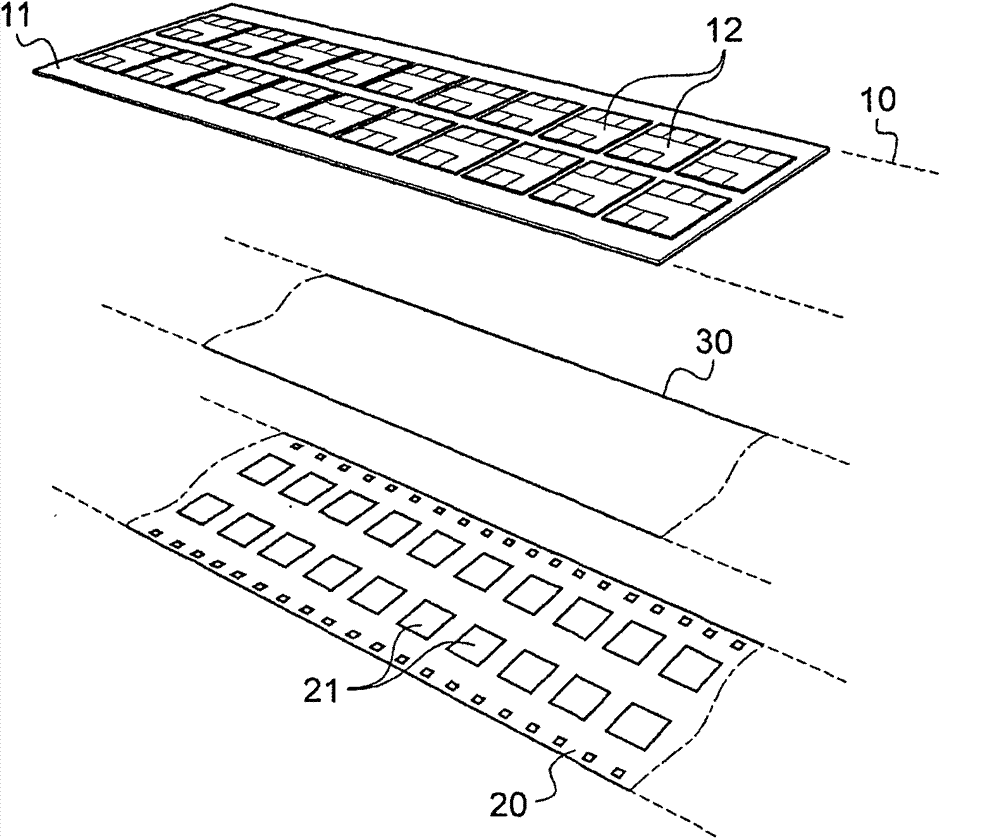

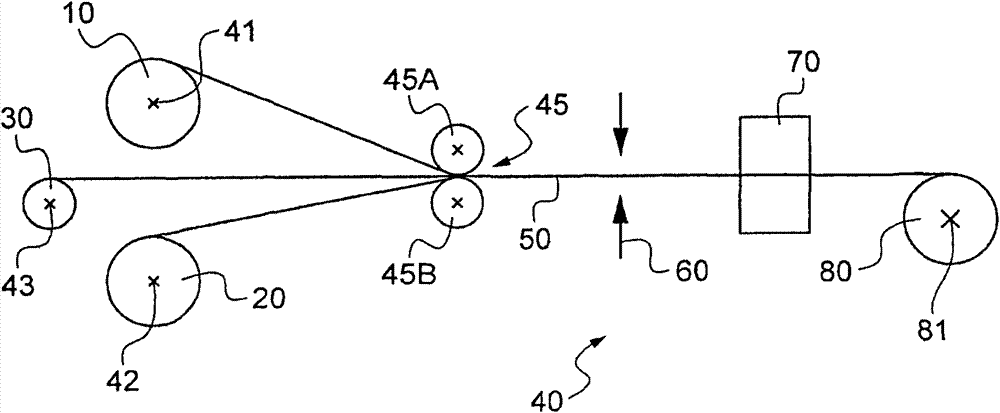

[0065] figure 1 Three bands are shown in a schematic manner, based on the three bands formed as in figure 2 Contact type cards in rolls obtained at the output of the machine shown.

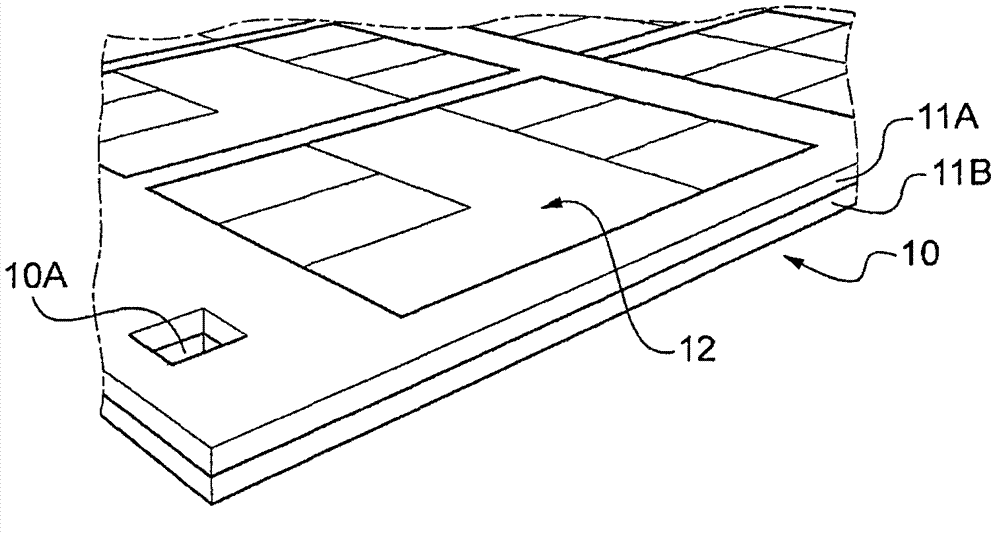

[0066] A first strip, referenced 10 , comprises a continuous (that is to say without breaks outside the positioning holes, referenced 10A, especially near the longitudinal edges) support film 11 ; this support film is electrically insulating.

[0067] Formed on this support film are contact surfaces marked 12; each of these contact surfaces is formed by a plurality of contact areas defined in practice at least in part by a standard such as ISO standard 7816 provided by the given pattern; in fact, it is by means of these contact areas that the future microcircuit card will communicate with the outside by means of a card reader.

[0068] From image 3 It can also be seen that, image 3 Showing a portion of belt 10, each contact surface has at least six contact areas, corresponding to areas C1 t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com