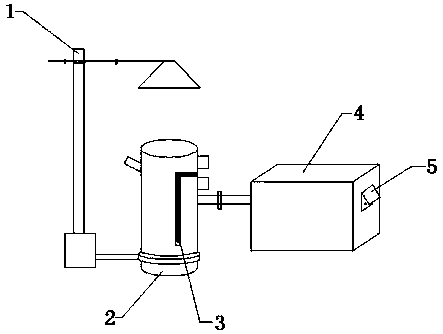

Liquid electronic chemicals quantitative filling machine

A technology for electronic chemicals and filling machines, which is used in liquid bottling, liquid processing, bottle filling, etc. The process of installing the machine, knowing the chemical liquid in the liquid storage tank, etc., to achieve the effect of improving convenience, wide application range, and convenient cleaning of the liquid storage tank

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

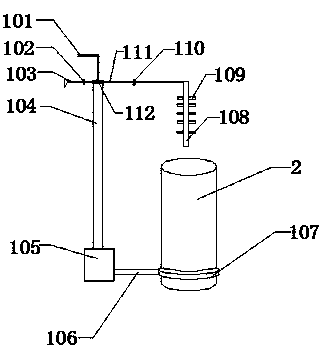

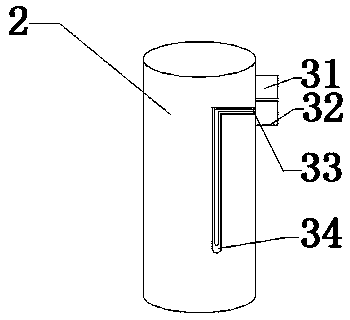

[0026] Specific implementation method: the staff starts the cylinder 105, the work of the cylinder 105 drives the straight shaft 106 to move downward, the disc 112 is driven downward by the straight shaft 106, the water pipe 2 111 is driven downward by the disc 112, the nozzle 1 103 and the water pipe The three 108 are driven downward by the water pipe two 111, and the nozzle two 109 is driven downward by the water pipe three 108. When it is necessary to clean the interior, close the on-off valve one 102, and move the water pipe three 108 down to the inside of the liquid storage tank 2. Water flows into the water pipe three 108 from the water pipe one 101 from the tap water pipe, and the water in the water pipe three 108 is sprayed out by the nozzle two 109 to clean the inside of the liquid storage tank 2. When it is necessary to clean the outside of the liquid storage tank 2, close the switch valve two 110 and work Personnel rotate water pipe two 111, make nozzle one 103 face ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com