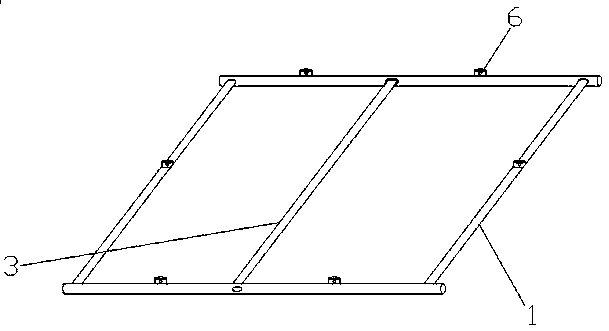

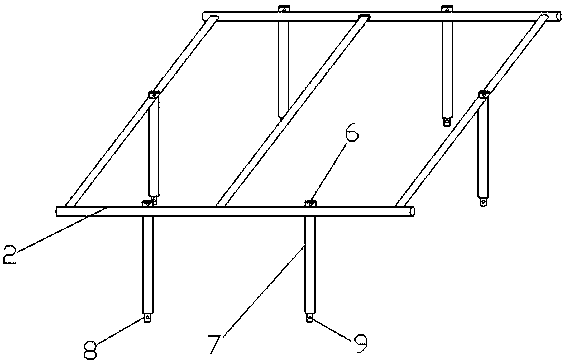

Primary truss and secondary truss spliced node structure

A node structure and main truss technology, which is applied in building construction and construction, can solve problems such as loose screws, no limit protection device setting, and unstable connection of horizontal frames, so as to improve the locking force and enhance stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

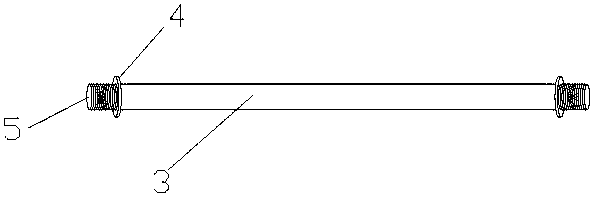

[0020] As a preferred embodiment of the present invention, the rotating disc 12, the limiting ring 13 and the threaded buckle 14 on the locking buckle 11 are a special-shaped fixed body formed by integral forging. The locking buckle formed by integral forging enhances the stability and fixity of the locking buckle when it is embedded and closed as a whole.

[0021] As a preferred embodiment of the present invention, the cylindrical diameter of the connecting post between the rotating disk 12 and the limiting ring 13 is larger than the cylindrical diameter of the threaded buckle 14 on the locking buckle 11 . The connecting column is larger than the threaded buckle, so that the limiting effect of the limiting ring is realized, and the locking force of the nut is enhanced through the limiting.

[0022] As a preferred embodiment of the present invention, the threaded hole 10 on the connecting buckle 6 is smaller than the size of the round hole on the opposite end and the through h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com