Mini MSD

A mini and handle technology, applied in the direction of contacts, electrical components, electric switches, etc., can solve the problem of excessive insertion force, and achieve the effect of compact structure, novel structure and good safety performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

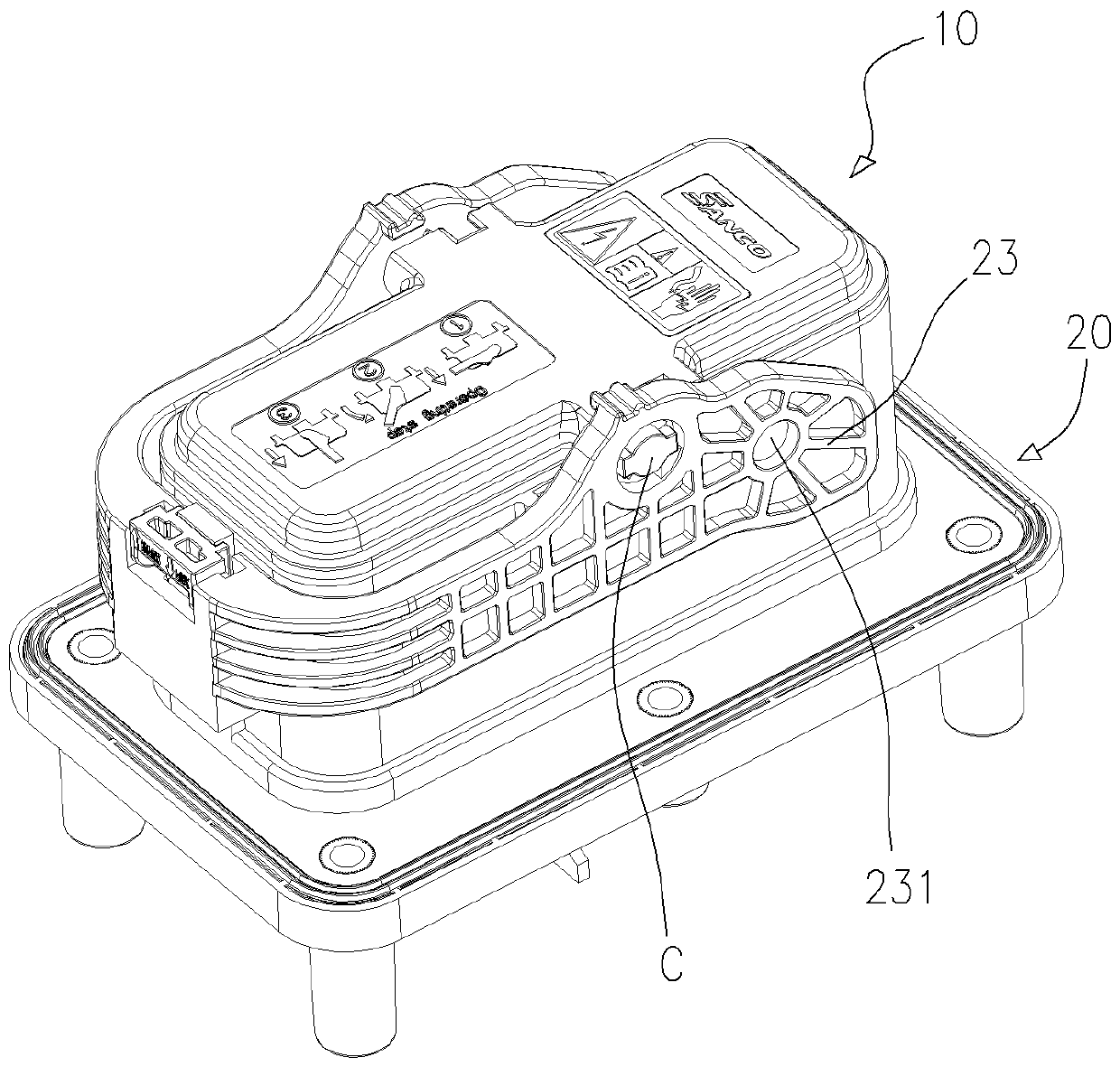

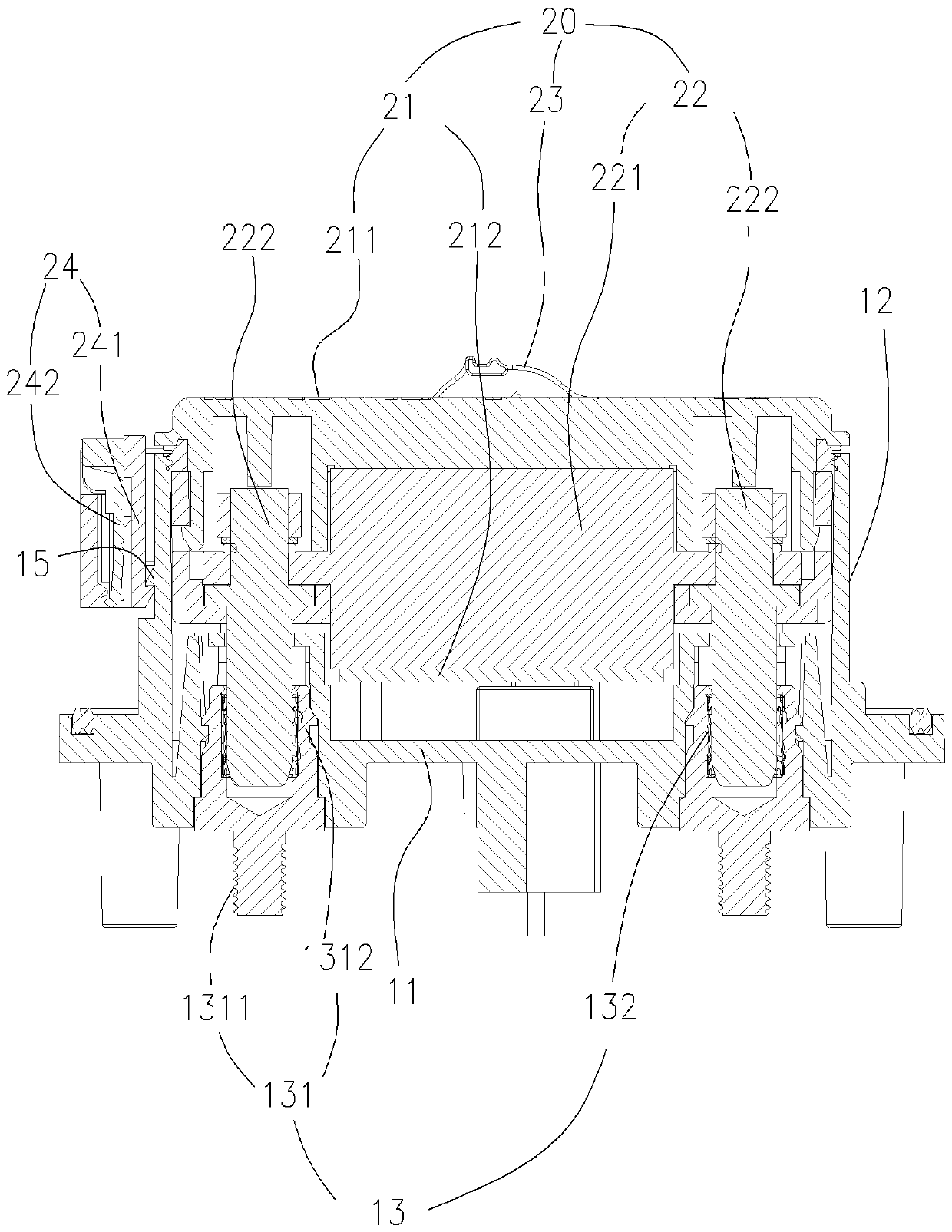

[0018] Such as Figure 1 to Figure 6 Shown is a kind of preferred concrete implementation example of the present invention, a kind of manual mini MSD, comprises:

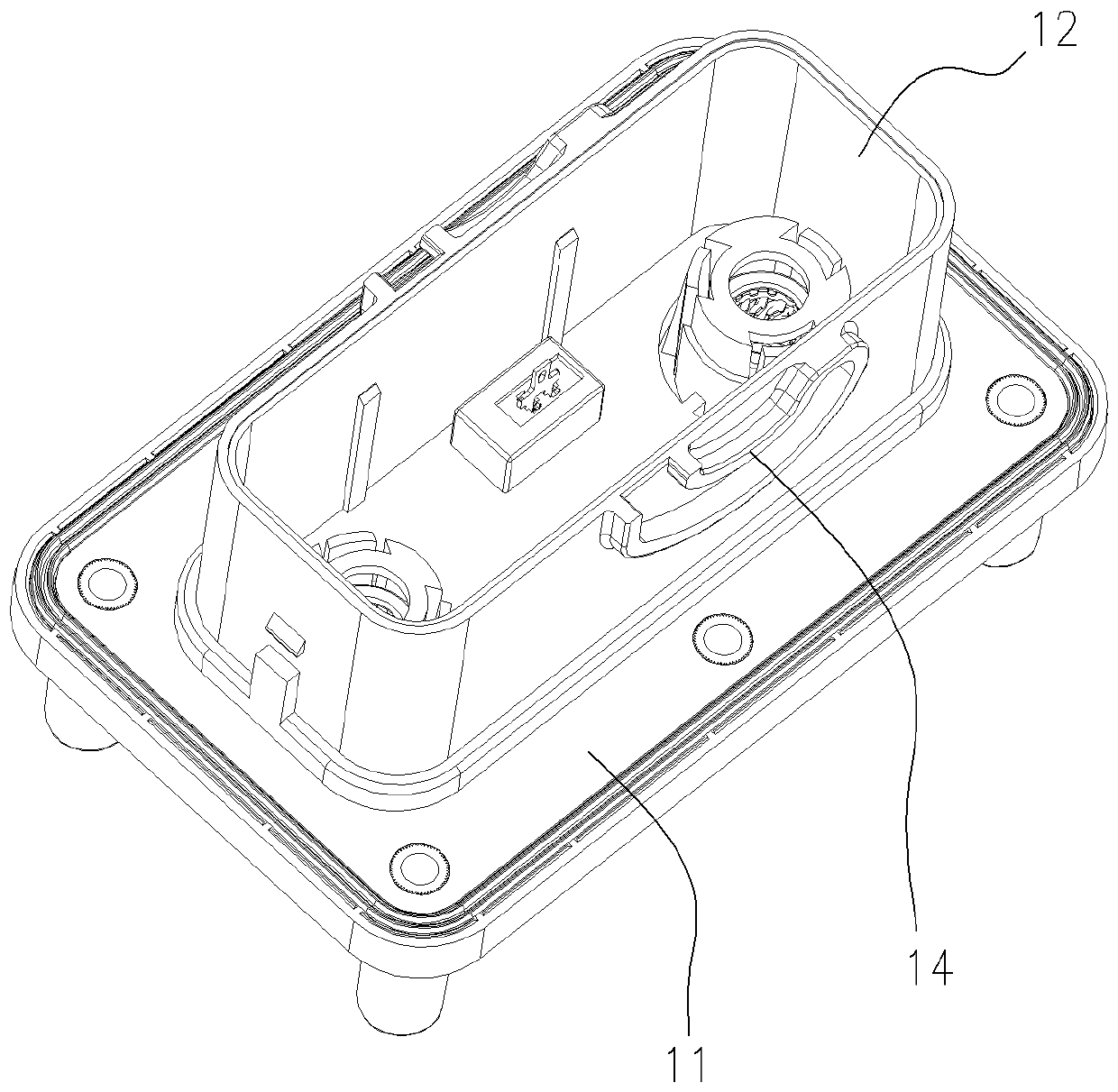

[0019] A socket 10, such as Figure 1 to Figure 5 As shown, the socket 10 includes a bottom plate 11 and a rectangular shell 12 provided with the upper side of the bottom plate 11. The bottom plate 11 inside the rectangular shell 12 is provided with a female terminal assembly 13. The outer surface of the rectangular shell 12 is provided with two Two corresponding ear-shaped guide rails 14 and undercuts 15;

[0020] A plug 20, such as figure 1 , figure 2 , Figure 6 As shown, the plug 20 includes a plug housing 21, a male terminal assembly 22 installed in the plug housing 21 and capable of being inserted into the female terminal 13, and a handle 23 sleeved on the outer surface of the plug housing 21. The handle 23 is provided with the inverted Buckle 16 locks or locks the locking device 24, the handle 23 is als...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com