Deep-sea leakage-free underwater hydraulic joint capable of rapidly discharging seawater

A hydraulic joint, no leakage technology, applied in the direction of mechanical equipment, couplings, etc., can solve the problems of low docking efficiency, affecting the working performance of components, waste, etc., to quickly drain seawater, solve environmental pollution and oil waste Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below with reference to the accompanying drawings and specific embodiments.

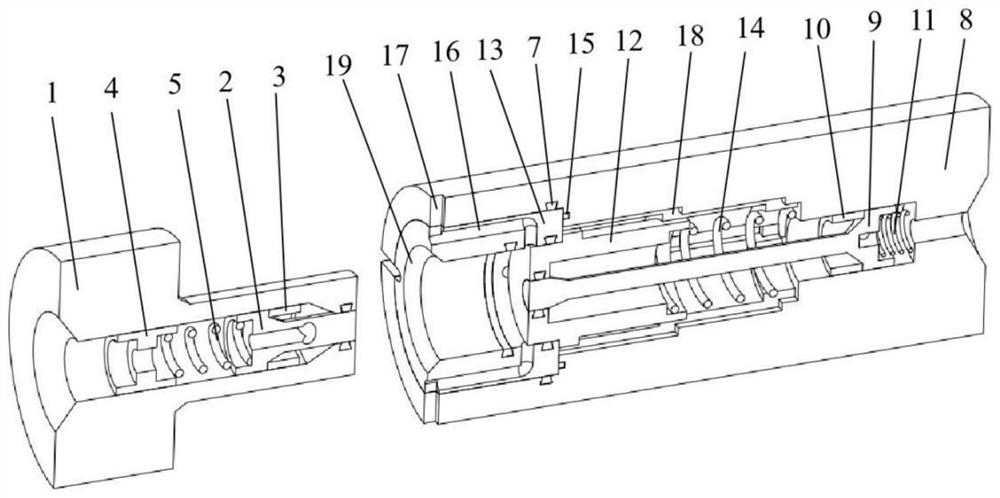

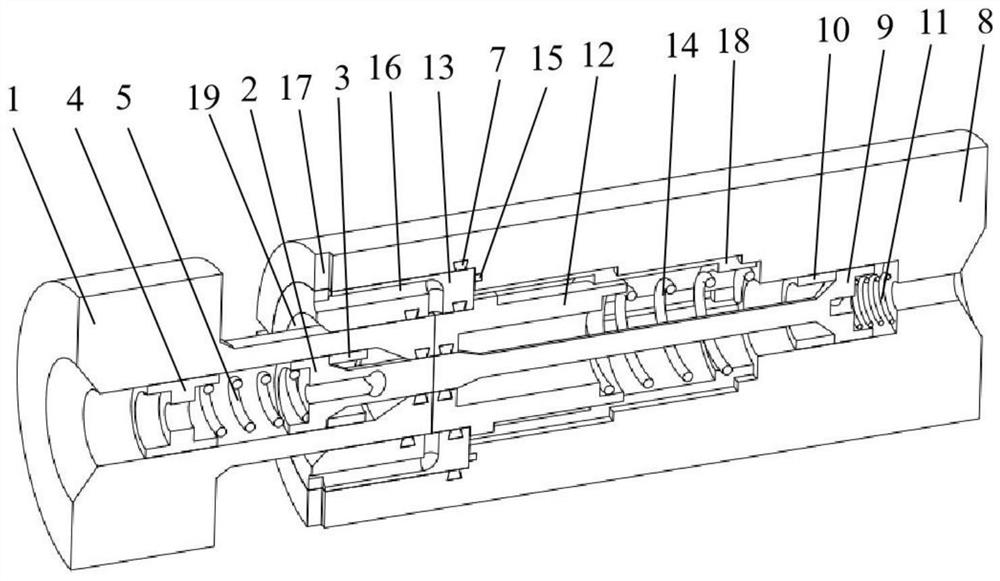

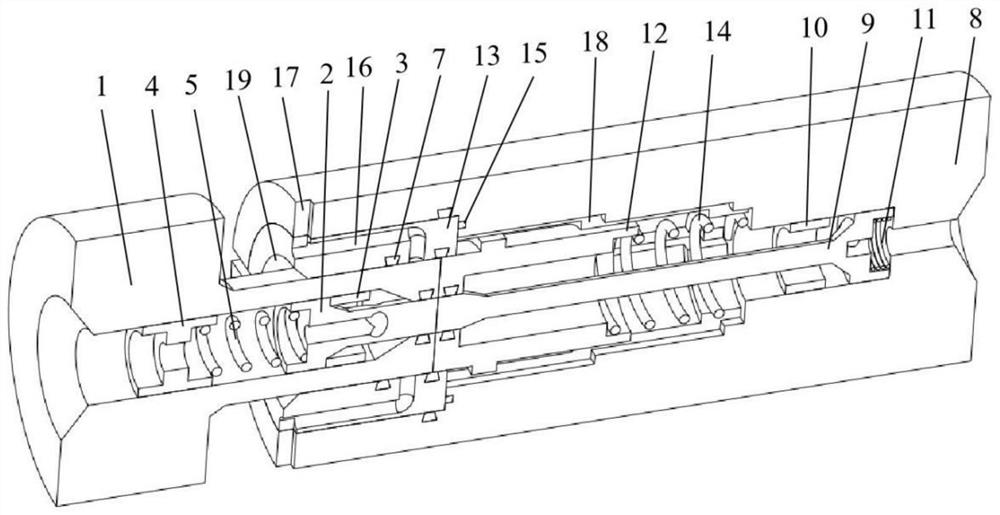

[0027] The invention relates to an underwater hydraulic joint, in particular to a high-reliability hydraulic joint with a fast-discharging seawater structure, a reasonable internal flow channel structure, a simple guiding structure, a reliable sealing structure, and a leak-free structure that can be used in deep sea environments. Sexual underwater hydraulic fittings. Including male sleeve 1, male thimble 2, male thimble upper limiter 3, male thimble lower limiter 4, male spring 5, connector 6, crown seal 7, female sleeve 8, female Head thimble 9 , female thimble limiting member 10 , female thimble spring 11 , sliding sleeve 12 , sliding sleeve limiting member 13 , sliding sleeve spring 14 , metal sealing ring 15 . The male head sleeve 1, the male head thimble lower limiter 4, the male head spring 5, the male head thimble upper limiter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com