Tension device for automatic pipe welder and automatic pipe welder

A tensioning device and automatic welding technology, which is applied in the direction of auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of pipe fitting welding influence, reduce welding efficiency, and cannot guarantee welding quality, so as to ensure coaxiality, welding The effect of quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

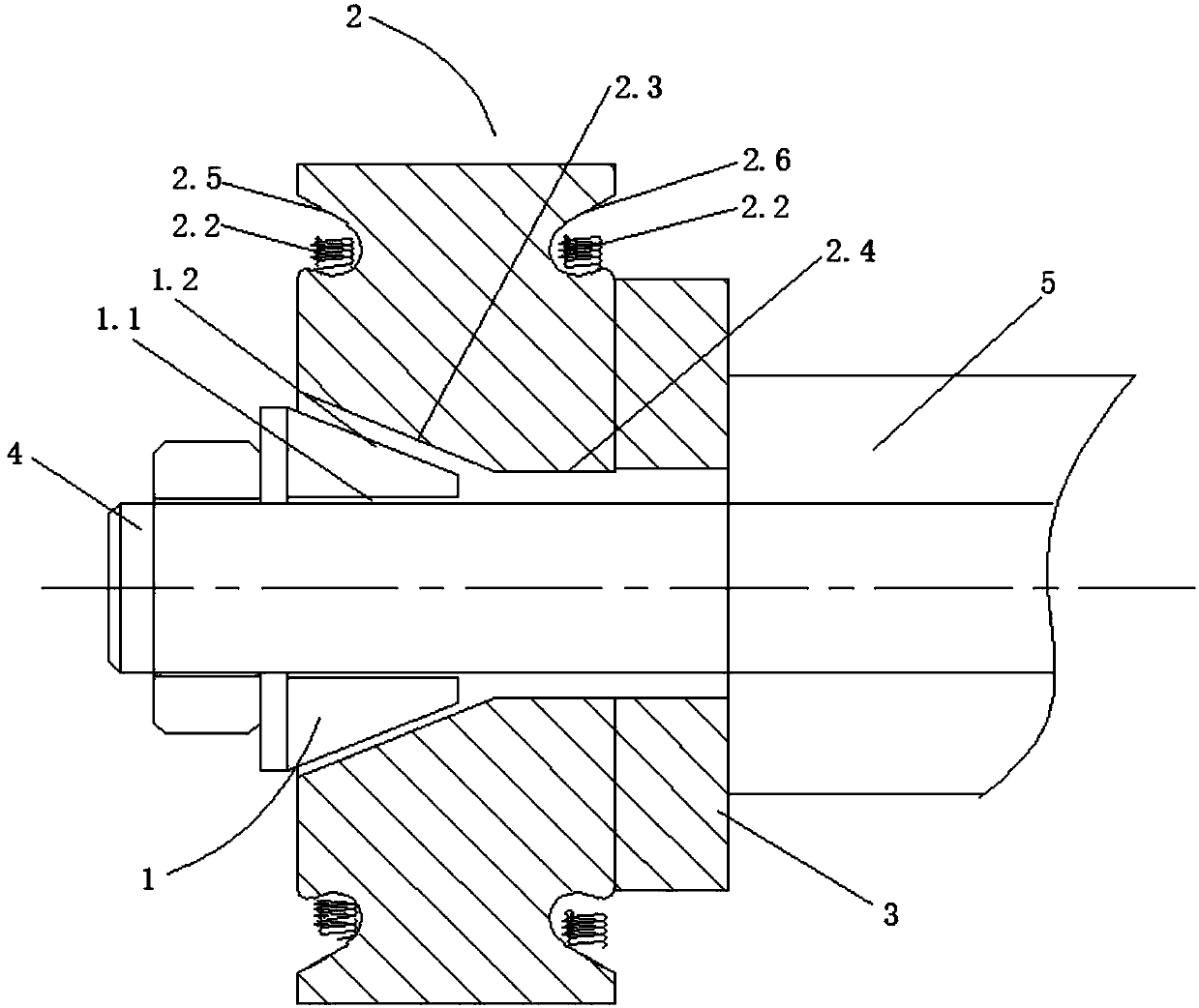

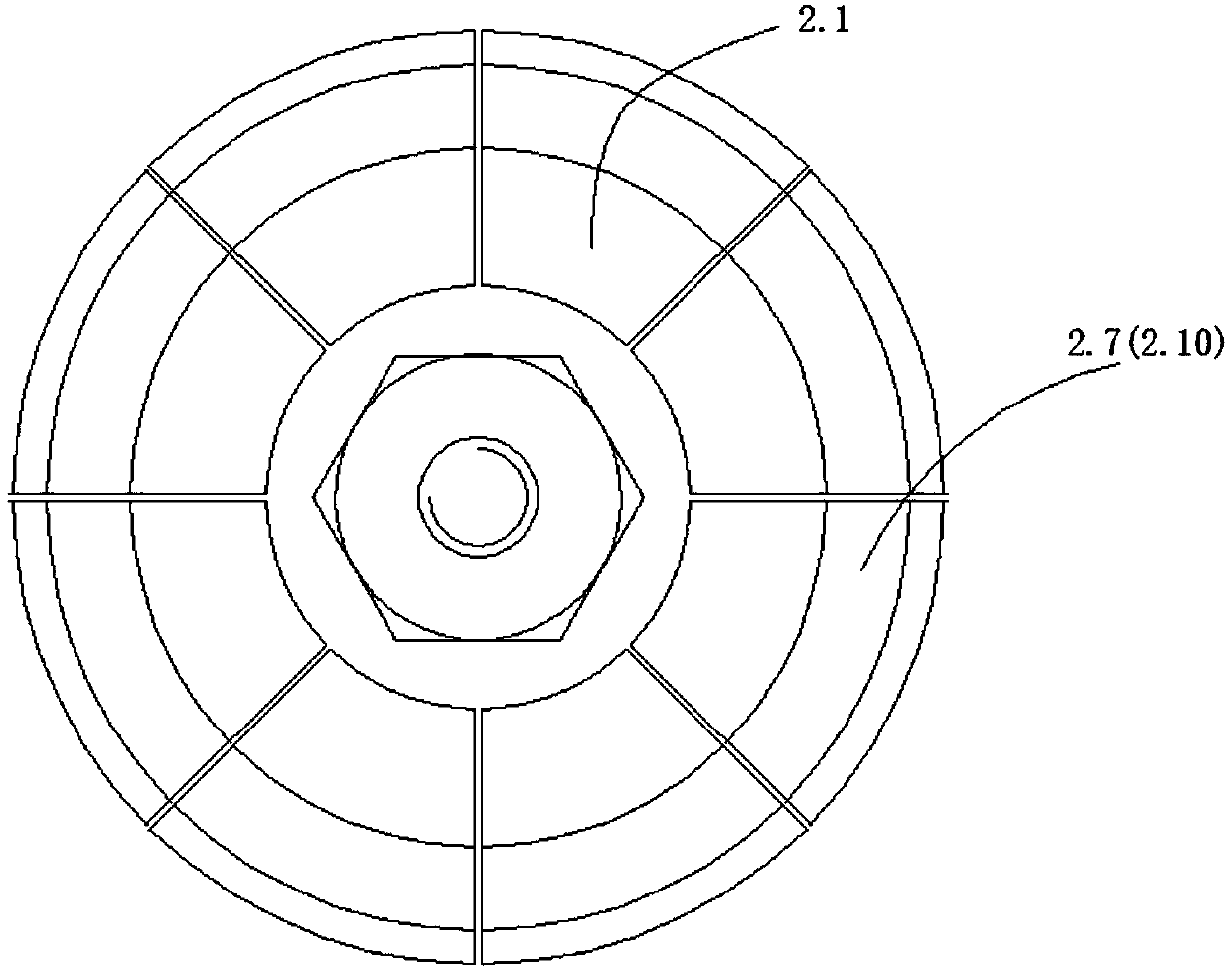

[0023] like Figures 1 to 2 As shown, the embodiment of the present invention provides a tensioning device for an automatic welded pipe machine. The tensioning device includes a conical top block 1 , an expansion sleeve 2 and a positioning platform 3 sequentially from front to back. In this embodiment, the middle part of the conical top block 1 is provided with a shaft hoop 1.1 matched with the inner rotating shaft 4 of the automatic pipe welding machine, and the rear end of the conical top block 1 is a conical body 1.2, wherein the conical top block The conical body 1.2 of 1 is sleeved into the expansion sleeve 2. The expansion sleeve 2 includes several arc-shaped expansion blocks 2.1, and several arc-shaped expansion blocks 2.1 are connected together by telescopic springs 2.2 to form the expansion sleeve 2. In this embodiment, the expansion sleeve 2 is composed of 8 arc-shaped The expansion block 2.1 is composed of 8 arc-shaped expansion blocks 2.1 through the telescopic sp...

Embodiment 2

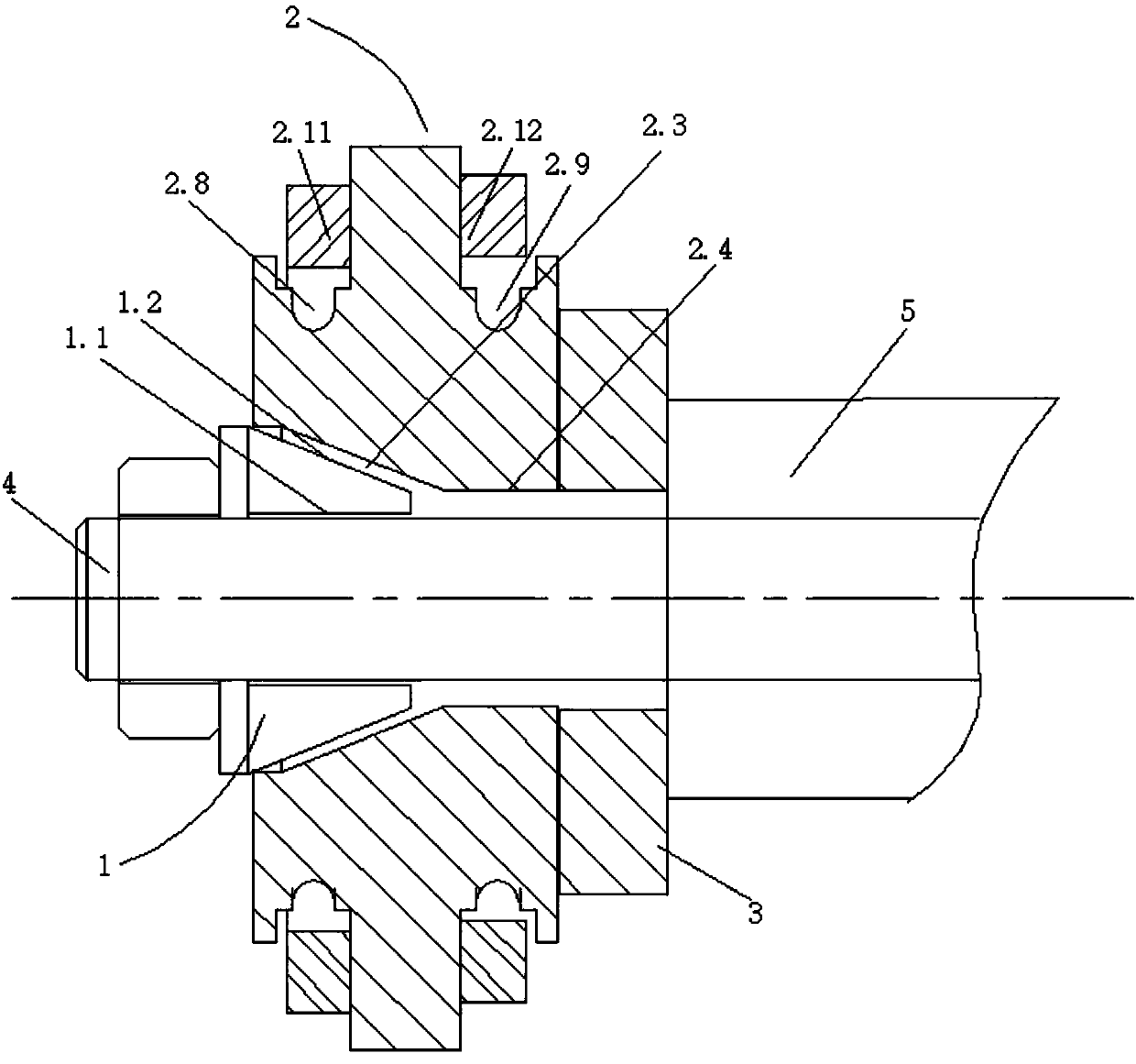

[0026] like image 3 As shown, the embodiment of the present invention provides a tensioning device for an automatic welded pipe machine. The tensioning device includes a conical top block 1 , an expansion sleeve 2 and a positioning platform 3 sequentially from front to back. In this embodiment, the middle part of the conical top block 1 is provided with a shaft hoop 1.1 matched with the inner rotating shaft 4 of the automatic pipe welding machine, and the rear end of the conical top block 1 is a conical body 1.2, wherein the conical top block The conical body 1.2 of 1 is sleeved into the expansion sleeve 2. The expansion sleeve 2 includes several arc-shaped expansion blocks 2.1, and several arc-shaped expansion blocks 2.1 are connected together by telescopic springs 2.2 to form the expansion sleeve 2. In this embodiment, the expansion sleeve 2 is composed of 8 arc-shaped The expansion block 2.1 is composed of 8 arc-shaped expansion blocks 2.1 through the telescopic spring 2....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com