Deflashing device

A technology for removing flashes and workpieces, which is applied in the field of devices for removing flashes of non-metallic materials. It can solve the problems of reducing the working efficiency of the motor, affecting the appearance of the product, and troublesome disassembly and replacement. It is convenient for daily maintenance and replacement of parts, and convenient for statistical work. Quantity, the effect of improving the efficiency of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

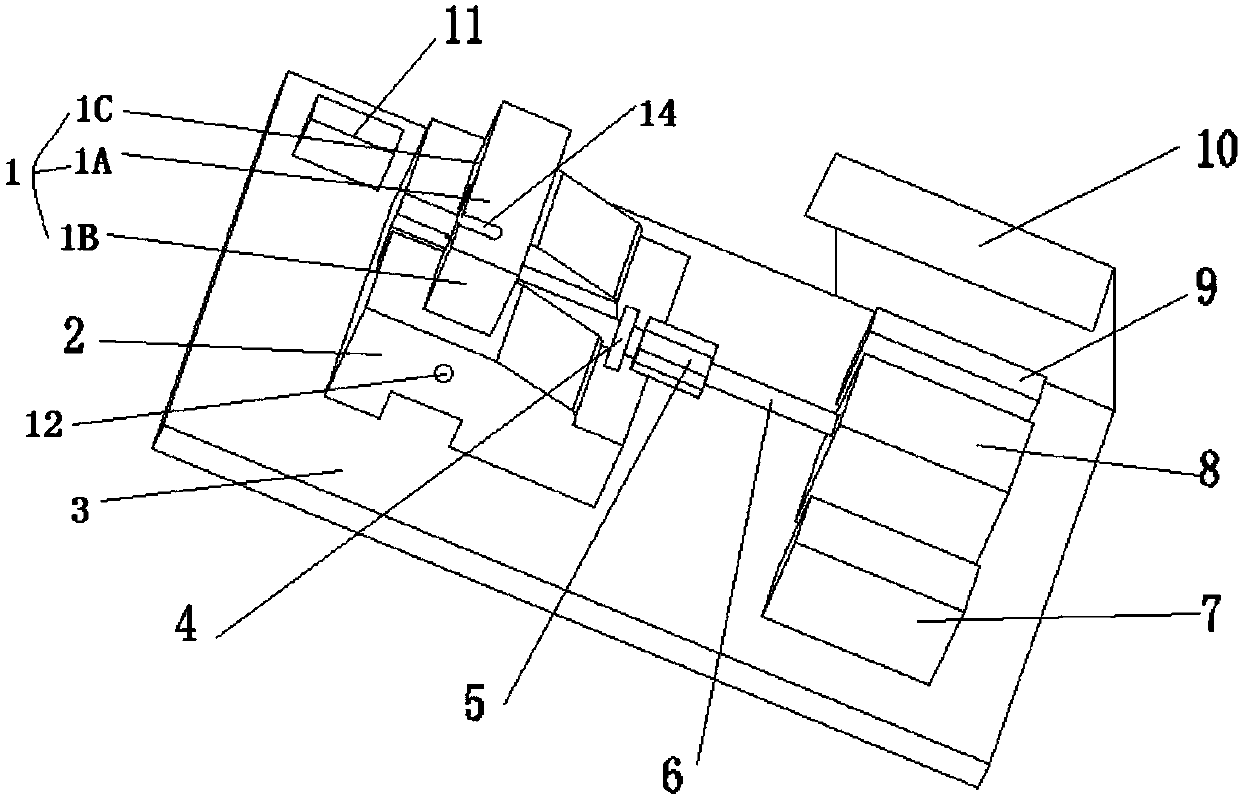

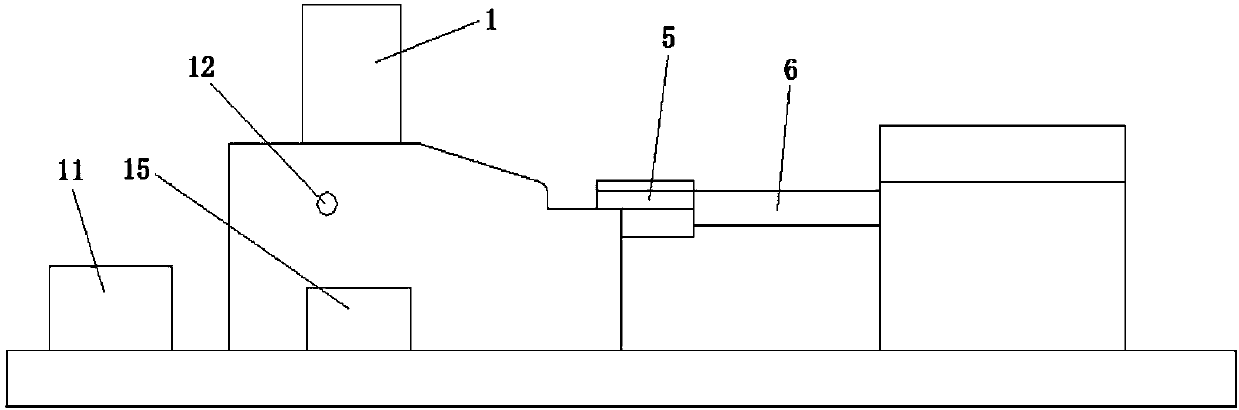

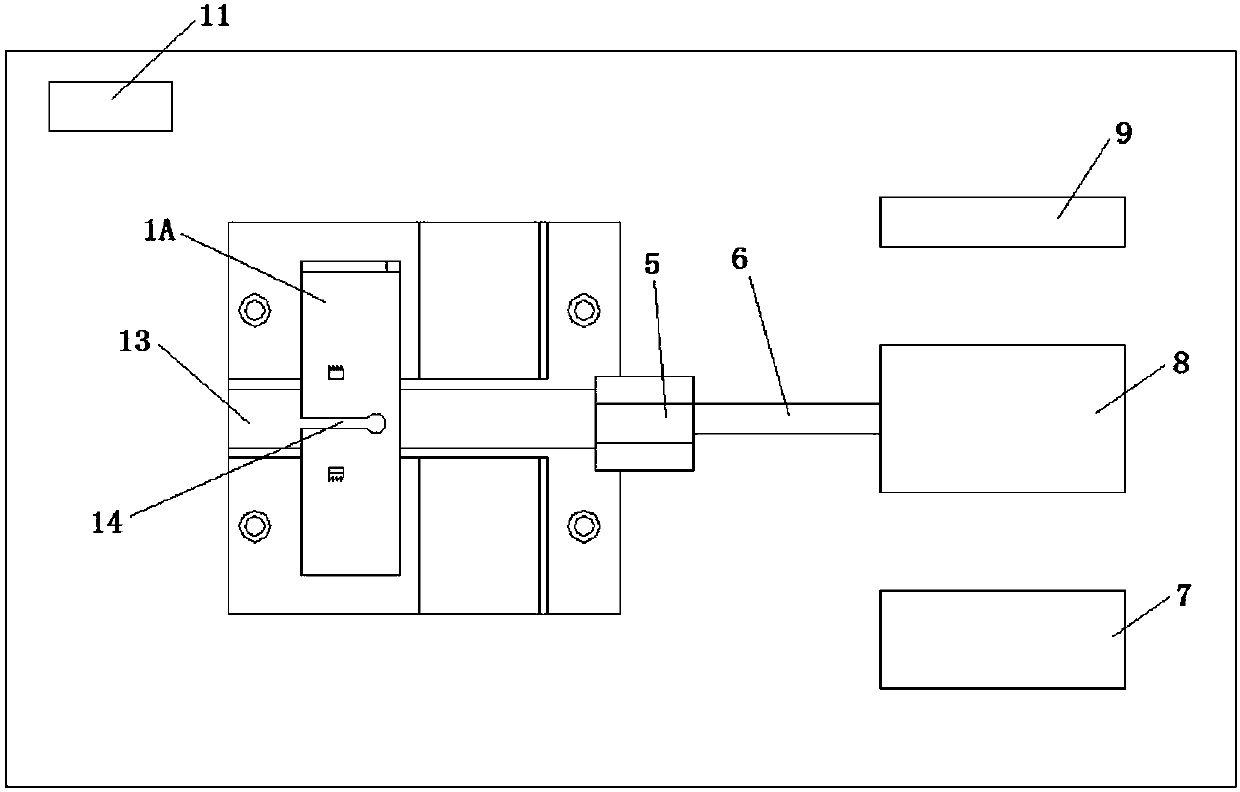

[0023] In the following detailed description, the deflashing device of the present invention will be described in detail with reference to the accompanying drawings and exemplary embodiments.

[0024] In an exemplary embodiment of the present invention, the deflashing device may include a cutting unit, a guiding unit, and a power unit for driving the guiding unit. Wherein, the cutting unit comprises a channel for the workpiece to pass through and a deburring knife positioned on the inner wall of the channel, the cutting edge of the deburring knife is arranged perpendicular to the moving direction of the workpiece and acts on the surface of the workpiece to remove the workpiece when the workpiece passes through the channel The flash on the surface, the guide unit includes a push rod and a push block for pushing the workpiece, the front end of the push rod is connected with the top block, and the rear end of the push rod is connected with the power unit. The shape of the deburri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com