A solid catalyst component, catalyst system and prepolymerized catalyst for olefin polymerization

A solid catalyst and olefin polymerization technology, applied in the field of olefin polymerization catalysts, can solve the problems of unstable compounds, unfavorable environmental protection and safety, strong corrosion, etc., and achieve the effect of improving polymerization activity, excellent comprehensive performance and high tacticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

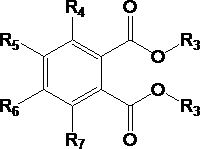

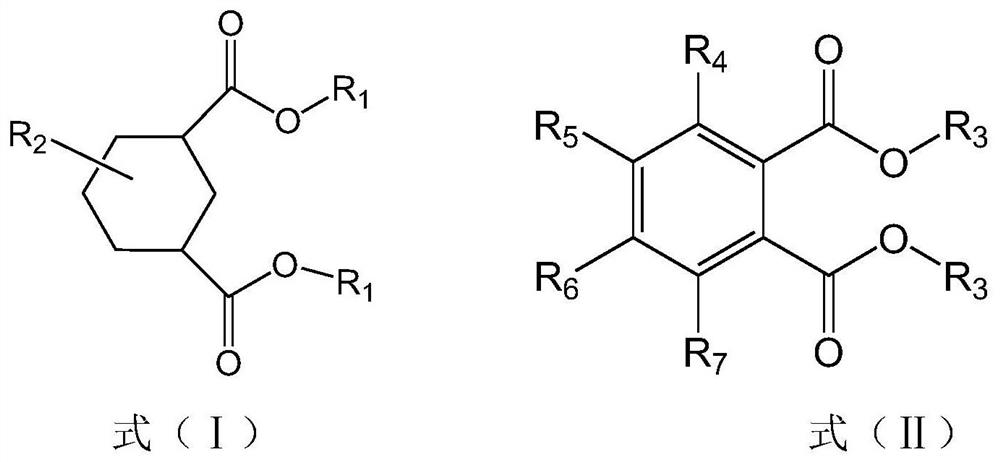

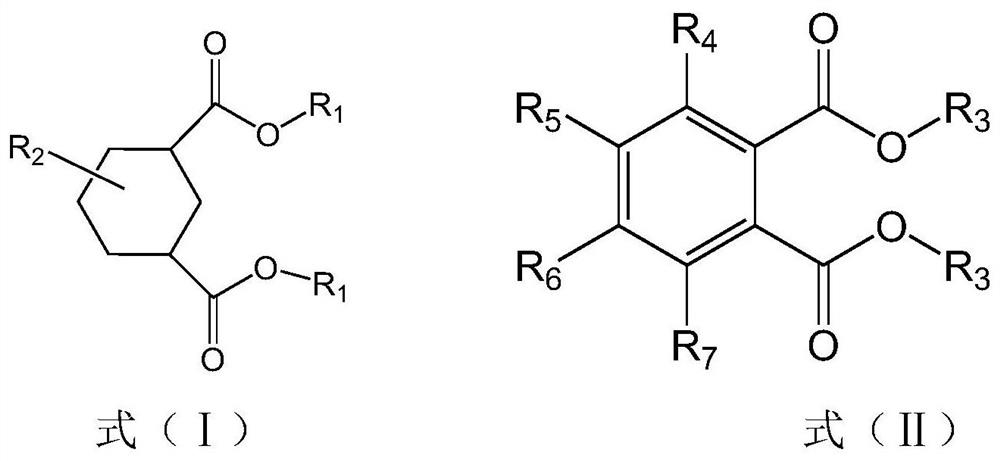

[0036] According to one embodiment, the solid catalyst component comprises a reaction product of a magnesium compound, a titanium compound, and an internal electron donor compound, wherein the molar ratio of the magnesium compound, titanium compound, and internal electron donor compound can be 1:( 0.5~150): (0.02~0.5).

[0037] Wherein, the magnesium compound can be selected from magnesium dihalide, alkoxy magnesium, alkyl magnesium, hydrate or alcoholate of magnesium dihalide, and a halogen atom in the molecular formula of magnesium dihalide replaced by alkoxy or haloalkoxy At least one of the derivatives substituted by the group.

[0038] Preferably, the magnesium compound is a magnesium dihalide and / or an alcoholate of magnesium dihalide.

[0039] Further preferably, the magnesium compound is an alcoholate of magnesium dihalide.

[0040] In the present invention, the alcoholate of magnesium dihalide can be expressed as MgX 2 pR'OH, X is a halogen, preferably Cl; p repres...

Embodiment 1~5 and comparative example 1

[0080] (1) Preparation of solid catalyst component a

[0081] In a 250mL reactor equipped with a reflux condenser, a mechanical stirrer and a thermometer and fully replaced by nitrogen, add 36.5mL of absolute ethanol and 21.3g of anhydrous magnesium chloride, heat up while stirring, and add 75mL of white oil after the magnesium chloride is completely dissolved. 75mL of silicone oil was kept at 120°C and stirred and mixed for 1 hour to obtain a mixture; in another 500mL reaction bottle with a high-speed stirrer, 112.5mL of white oil and the same volume of silicone oil were added in advance, preheated to 120°C, and the above The mixture was quickly pressed into the second reactor, maintained at 120°C and stirred at 3500rmp for 3 minutes; under stirring, the material was transferred to the third reactor that had previously added 1600mL hexane and cooled to -25°C until the transfer of the material was completed, and finally The temperature does not exceed 0°C; filter with suction,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com