Steel structure welding seam generating method

A technology for steel structures and steel components, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as inability to obtain welds, achieve accurate and reliable results, fast judgment speed, and reduce production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

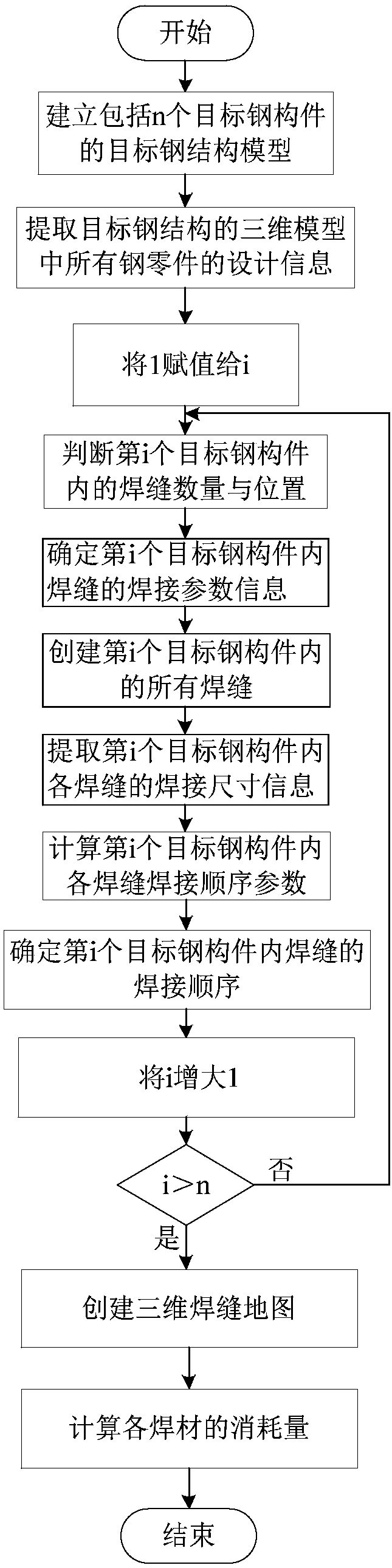

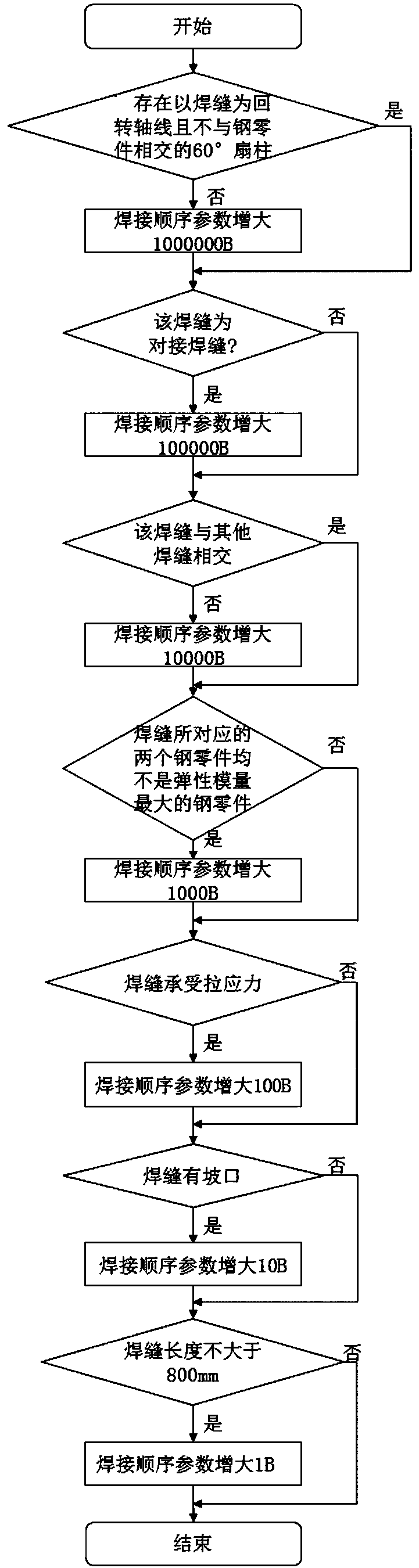

[0042] The present invention will be further described below in conjunction with the drawings.

[0043] A method for generating welds in steel structures, the specific steps are as follows:

[0044] Step 1: Use steel structure design software to build a three-dimensional model of the target steel structure. Steel structure design software can use Tekla. The target steel structure is composed of n target steel components. Number n target steel components. And the steel parts in the n target steel components are respectively numbered secondary.

[0045] Step 2: Extract the design information F of all steel parts in the three-dimensional model of the target steel structure ik , I represents the number of the target steel component where the corresponding steel part is located, and k represents the number of the corresponding steel part in the i-th target steel component. The design information includes steel part number i-k, steel part material, steel part stress size, steel part str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com