Liquid crystal screen detection method

A detection method and liquid crystal screen technology, applied in nonlinear optics, instruments, optics, etc., can solve problems such as inaccurate detection results and inability to judge all problems, and achieve the effects of improving detection efficiency, fast judgment speed, and accurate judgment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings.

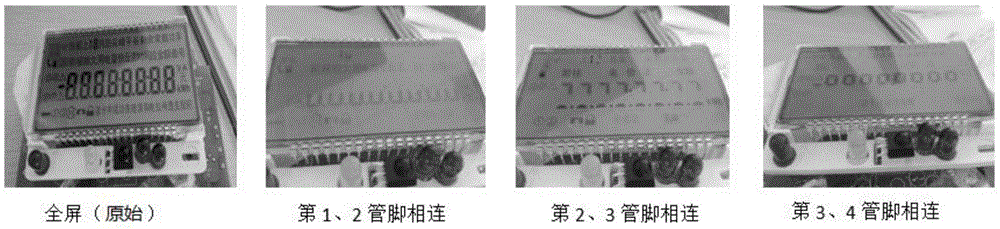

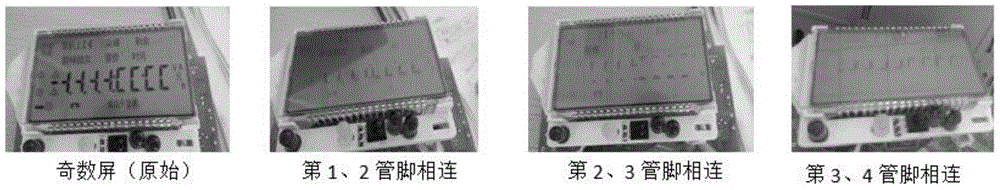

[0019] A method for detecting an electric meter liquid crystal screen: including: storing a standard image, the standard image is determined in a pre-experiment, in the full-screen image, the first screen image and the second screen image under no error welding and various error welding situations At least two types; the image output by all pins is defined as a full-screen image, the image output by only a part of the pins is defined as the first screen image, and the image output by only the rest of the pins is defined as the second screen image.

[0020] For the liquid crystal screen to be detected, obtain the image to be inspected, the image to be inspected is at least two images corresponding to the above-mentioned standard image; the image to be inspected is compared with the standard image, and when each type of image behaves the same, the welding corres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com