Preparation method of soft-boiled eggs

A soft-boiled egg and egg technology, which is applied in the field of preparation of salted soft-boiled eggs, can solve the problems that the taste cannot meet the requirements of consumers, the boiling process is short, and the egg white and egg yolk overflow, so as to achieve complete microbial killing and good taste. Delicate and smooth, the effect of increasing the penetration speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

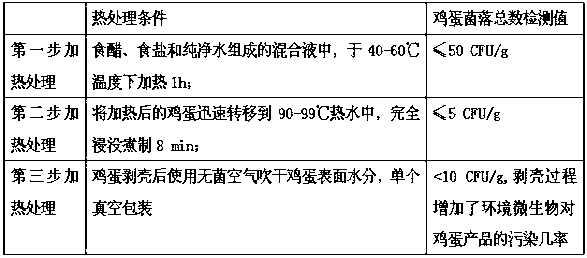

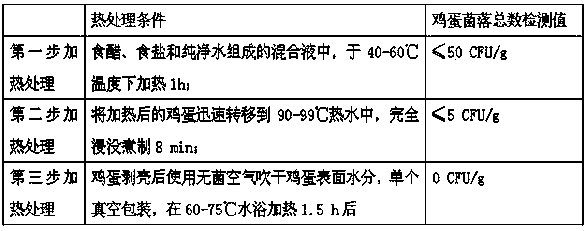

Embodiment 1

[0033] Select eggs with no cracks and no damage on the surface of the eggs, the weight range is 55-65g, the freshness is 60-70HU (egg freshness unit: Haugh Units, HU), the quantity is 30, and the blunt end is beaten with the bottom of a small steel spoon until the cracks After diverging, according to the weight ratio of eggs, salt, vinegar and purified water as 1:0.01:0.1:8, put the eggs into 14.4kg of purified water, add 180g of salt and 18g of vinegar, keep in a water bath at 40°C for 3 hours, then Quickly transfer to 97°C hot water for 5 minutes, then transfer to 0-4°C ice water to cool down for 30 minutes, then peel off the shells to obtain 29 soft-boiled eggs with shells intact, with a yield of 97%. After drying the surface of the soft-boiled eggs, A single vacuum-packed soft-boiled egg, then placed in a water bath at 75°C for 1.5 hours, cooled to 0-4°C in ice water, refrigerated at 0-4°C, stored for 6 months, tested for Escherichia coli, total bacteria and Taste: Escheri...

Embodiment 2

[0035] Select eggs with no cracks and no damage on the surface of the eggs. The weight range is 55-65g, the freshness is 60-70HU, the quantity is 40, and the blunt end is beaten with the bottom of a small steel spoon until the cracks diverge. The weight ratio with purified water is 1:0.02:0.2:9. Put eggs into 21.6kg of purified water, add 432g of salt and 43.2g of vinegar, keep in a water bath at 50°C for 2h, then quickly transfer to hot water at 94°C for 7min Then transfer to 0-4 ℃ ice water to cool down for 30 minutes and peel off the shells to obtain 39 soft-boiled eggs with shells intact, with a yield of 97.5%. After keeping it in a water bath at 65°C for 2 hours, cool it down to 0-4°C in ice water, refrigerate at 0-4°C, and store it for 6 months, then detect Escherichia coli, total bacteria and mouthfeel. Escherichia coli is less than 10MPN / g, total bacteria Less than 50CFU / g, the egg white is white and shiny, the taste is soft and elastic, the egg yolk is gelatinous, par...

Embodiment 3

[0037]Select eggs with no cracks and no damage on the surface of the eggs. The weight range is 55-65g, the freshness is 60-70HU, the quantity is 50, and the blunt end is beaten with the bottom of a small steel spoon until the cracks diverge. The weight ratio with purified water is 1:0.04:0.4:10. Put the eggs into 30kg of purified water, add 1200g of salt and 120g of vinegar, keep in a water bath at 60°C for 2 hours, then quickly transfer to hot water at 92°C for 10 minutes and then transfer Cool down in ice water at 0-4°C for 30 minutes and peel off the shells to obtain 48 soft-boiled eggs with a yield of 98%. After drying the surface of the soft-boiled eggs, vacuum-pack the soft-boiled eggs individually and place them at 60°C After keeping in a water bath for 3 hours, cool down to 0-4°C in ice water, refrigerate at 0-4°C, store for 6 months, test E. coli, total bacteria and taste, E. coli is less than 10MPN / g, total bacteria is less than 50 CFU / g, the egg white is white and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com