Automatic timing ball recovering device

An automatic and oil recovery technology, applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc. Reliability, lower maintenance costs, and excellent anti-theft oil performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

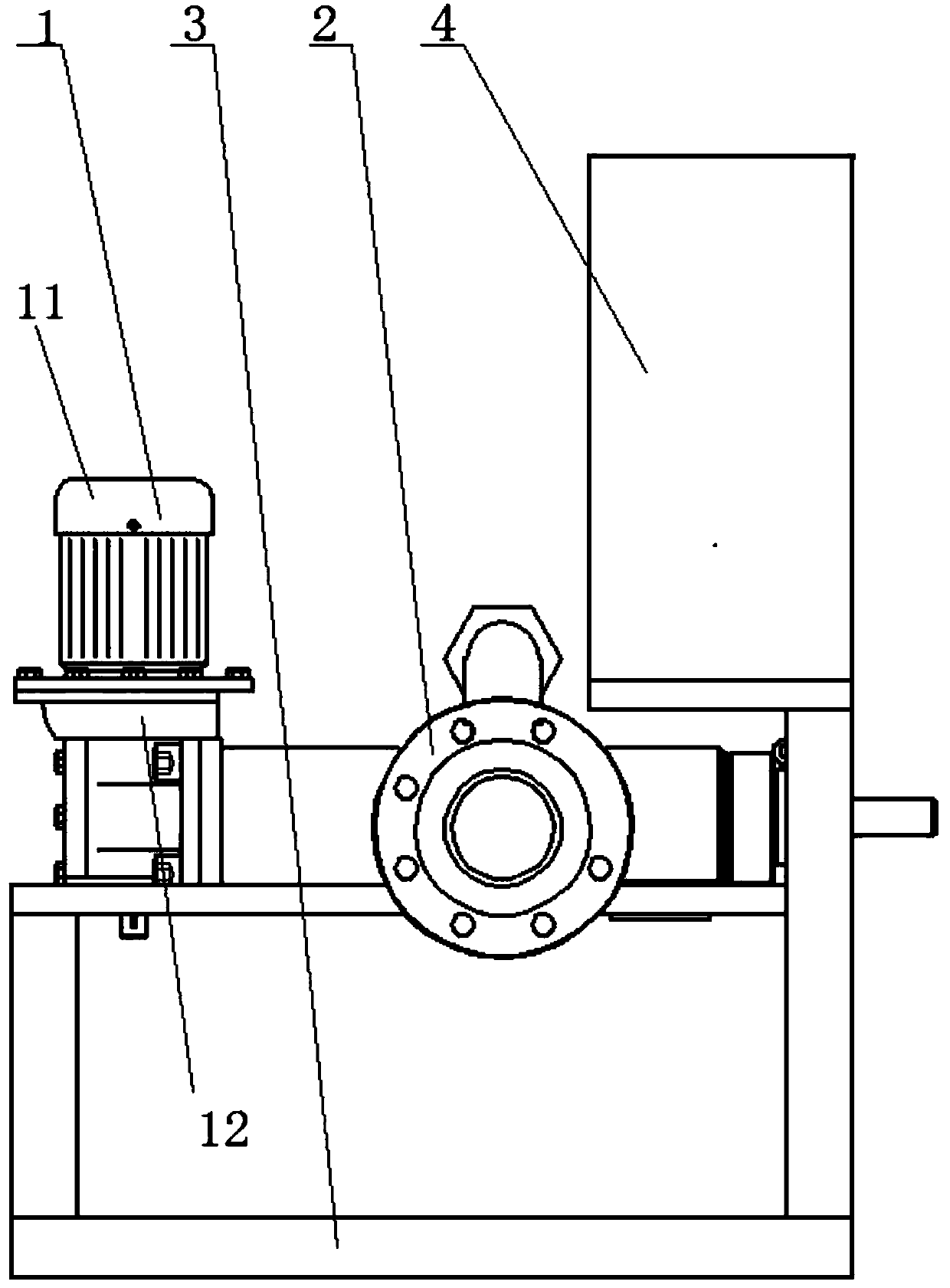

Embodiment 1

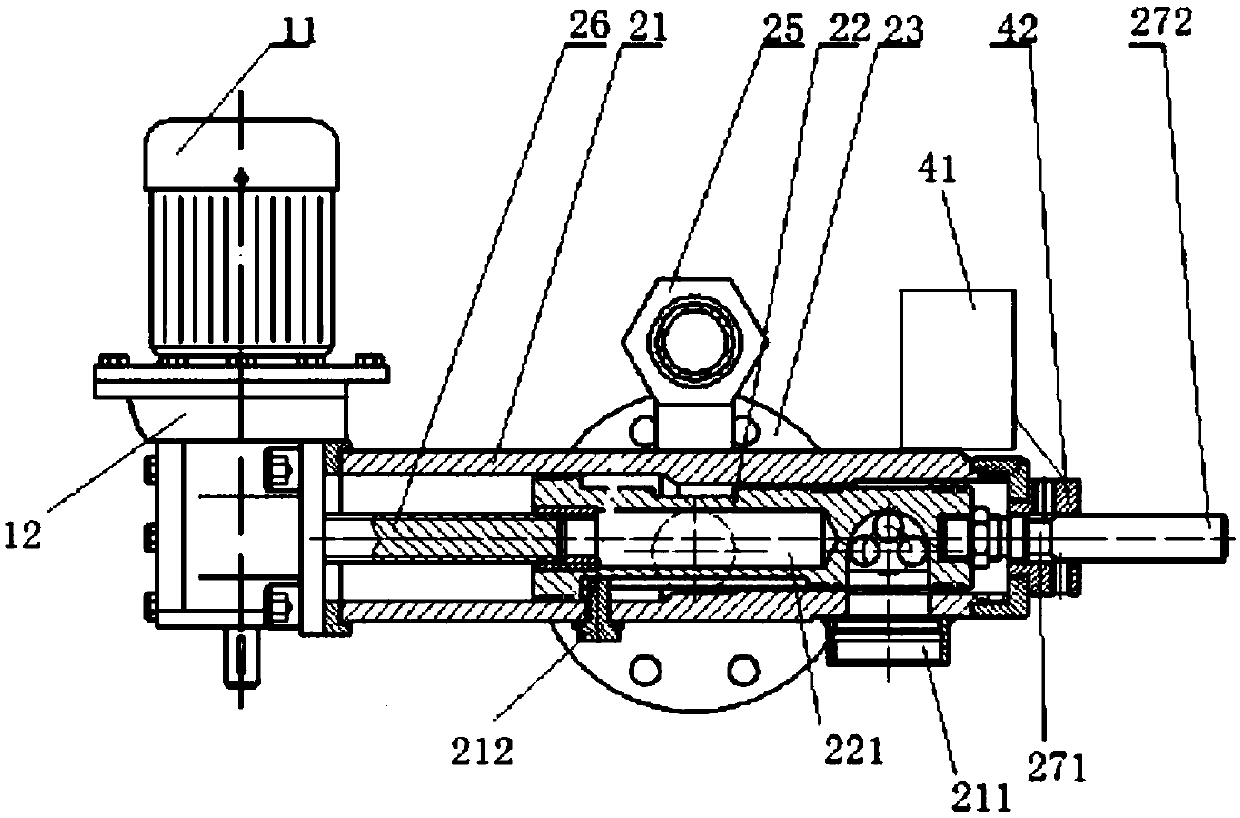

[0026] Such as image 3 As shown, in this embodiment, the travel switch 27 is composed of a connecting rod 271, a U-shaped induction switch 272 and an anti-loosening nut; one end of the connecting rod 271 is provided with an external thread, which is threaded through the anti-loosening nut and the plunger 22 , and the other end is fixedly connected with the U-shaped inductive switch 272, and the U-shaped inductive switch 272 is in point contact with the limit sensor 42.

[0027] When in use, the user sets the time and duration for the device to be turned on in the PLC controller 41. When the set time is reached, the PLC controller 41 controls the motor 11 to turn on, the motor 11 drives the reducer 12 to rotate, and the reducer 12 drives the screw rod 26 to rotate. , the plunger 22 is cylindrical to ensure that it will not rotate when moving; the plunger 22 screwed with the screw rod 26 starts to move to the left in the body 21, and the ball-taking groove 221 on the plunger 22...

Embodiment 2

[0031] Such as image 3 As shown, in this embodiment, the travel switch 27 is composed of a connecting rod 271, a U-shaped induction switch 272 and an anti-loosening nut; one end of the connecting rod 271 is provided with an external thread, which is threaded through the anti-loosening nut and the plunger 22 , and the other end is fixedly connected with the U-shaped inductive switch 272, and the U-shaped inductive switch 272 is in point contact with the limit sensor 42.

[0032] When in use, the user sets the time and duration for the device to be turned on in the PLC controller 41. When the set time is reached, the PLC controller 41 controls the motor 11 to turn on, the motor 11 drives the reducer 12 to rotate, and the reducer 12 drives the screw rod 26 to rotate. , the plunger 22 is cylindrical to ensure that it will not rotate when moving; the plunger 22 screwed with the screw rod 26 starts to move to the left in the body 21, and the ball-taking groove 221 on the plunger 22...

Embodiment 3

[0036] Such as image 3 As shown, as a preferred implementation of the above embodiment, in this embodiment, the travel switch 27 includes a connecting rod 271, a U-shaped induction switch 272 and an anti-loosening nut; the anti-loosening nut at one end of the connecting rod 271 passes through the connecting rod The connecting rod 271 and the U-shaped sensor switch 272 are screwed to the plunger 22 by the screw thread on the upper body. The connecting rod 271 passes through the body 21 and contacts with the limit sensor 42 installed on the body 21. The connecting rod 271 is in addition One end is fixedly connected with a U-shaped inductive switch 272 , and the U-shaped inductive switch 272 is in electrical contact with the limit sensor 42 .

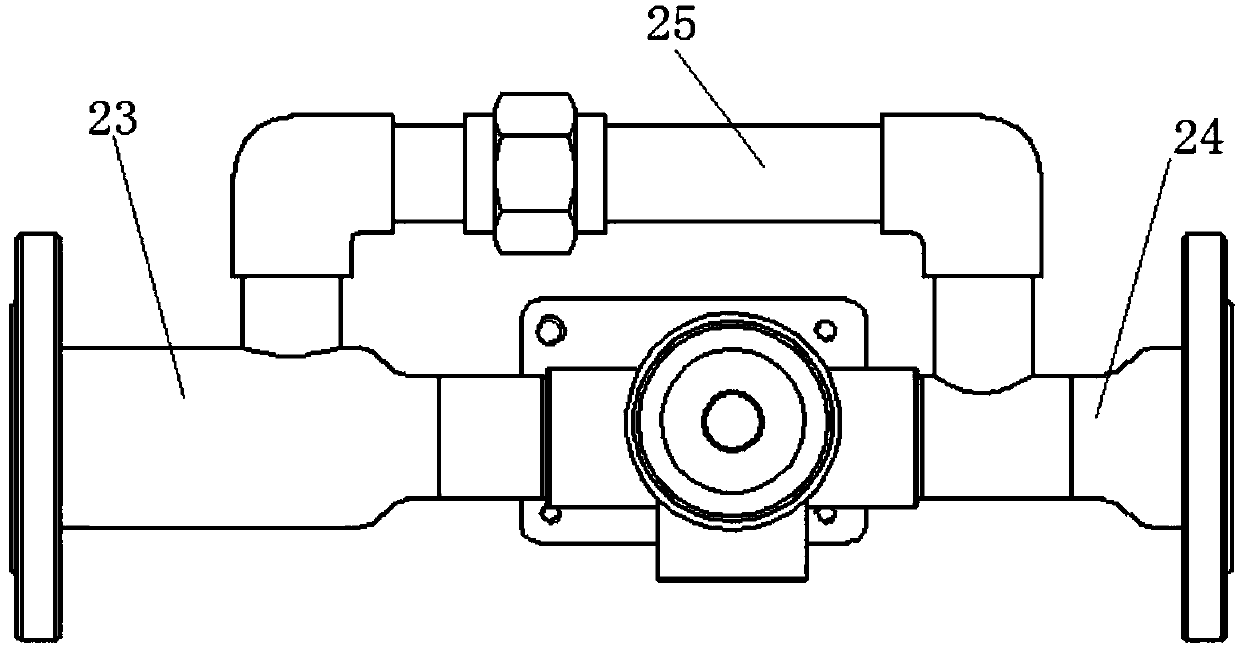

[0037] The ball-taking groove 221 is L-shaped, the inlet is at the same height as the flange nipple 23, and the outlet is at the same level as the ball outlet 211.

[0038] When in use, the user sets the time and duration for the device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com